Cooking utensil and preparation method thereof

A technology for cooking utensils and substrates, applied in the field of kitchen utensils, can solve the problems of low coating gloss, hardness, adhesion, poor labor hygiene environment, public hazards, etc., and achieves improved labor hygiene conditions, high spraying efficiency, and electromagnetic heating. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

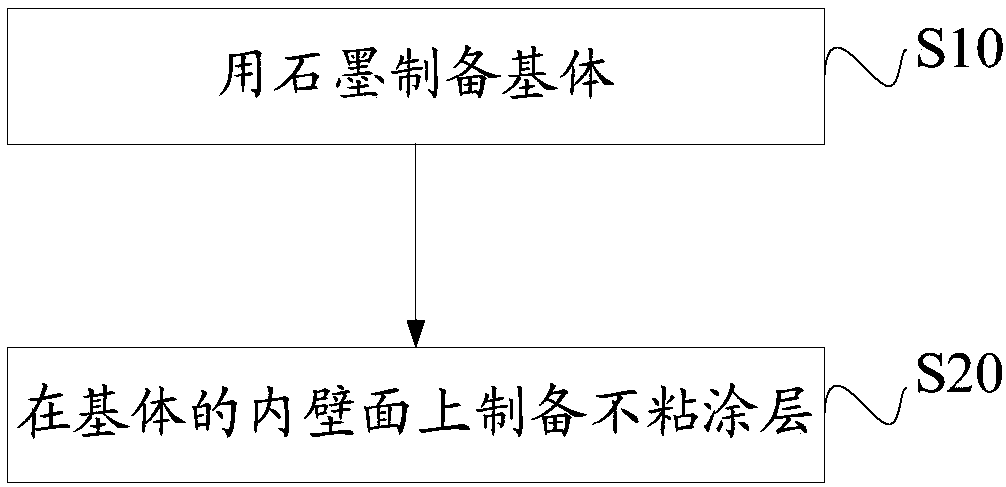

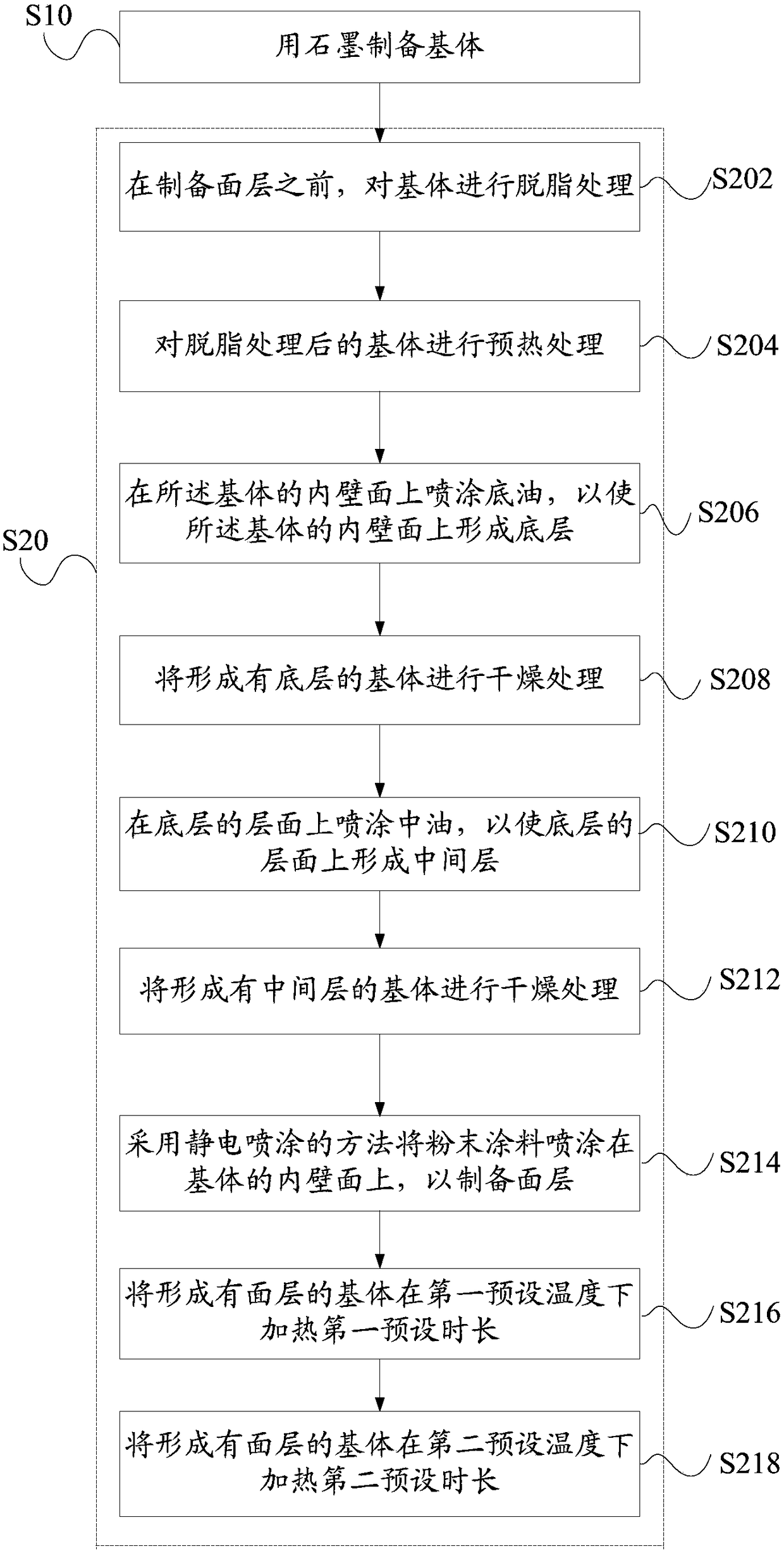

[0055] Such as figure 1 , image 3 and Figure 4 As shown, according to a preparation method of a cooker 100 provided in some embodiments of the present invention, the cooker 100 includes a base 10 and a non-stick coating 30, the base 10 is made of graphite, and the non-stick coating 30 is attached to the inner wall of the base 10 Above, the non-stick coating 30 includes a surface layer 303, and the preparation method of the cooker 100 includes: step S10, preparing the substrate 10 with graphite; step S20, preparing the non-stick coating 30 on the inner wall surface of the substrate 10, wherein the step S20 specifically It includes: step S214, spraying powder paint on the inner wall surface of the base body 10 by electrostatic spraying method, so as to prepare the surface layer 303.

[0056] The preparation method of the cooker 100 provided by the above-mentioned embodiments of the present invention includes preparing the substrate 10 with graphite, and preparing a non-stick...

Embodiment 1

[0093] Graphite products are made by hot pressing and sintering graphite powder;

[0094] Use compressed air to remove surface dust before spraying base oil such as graphite pans and graphite plates, the air pressure is 6kg; and perform degreasing treatment to remove oil stains and impurities on the surface of the base 10. The degreasing process is 350 ° C for 15 minutes;

[0095] Sandblasting is not required before spraying, because graphite has good adsorption properties, and the sprayed primer, medium oil, PFA powder (powder coating) and the like can be well attached to the inner wall surface of the substrate 10;

[0096] Preheat the substrate to 50°C;

[0097] Before spraying, the powder is dispersed by a ball mill at a speed of 40 rpm for 60 minutes, and filtered by a filter screen. The base oil is filtered by 140 mesh, and the medium oil and powder coating are filtered by 100 mesh;

[0098] Spraying the bottom layer 301: the spraying paint is a special primer for PFA, t...

Embodiment 2

[0103] Graphite products are made by hot pressing and sintering graphite powder;

[0104] Graphite pans, graphite plates and other cooking utensils 100 use compressed air to remove surface dust before spraying the primer, and the air pressure is 8kg; and perform degreasing treatment to remove oil stains and impurities on the surface of the substrate 10. The degreasing process is 380 ° C for 10 minutes;

[0105] Sandblasting is not required before spraying, because graphite has good adsorption properties, and the sprayed primer, medium oil, PFA powder (powder coating) and the like can be well attached to the inner wall surface of the substrate 10;

[0106] Preheat the substrate to 70°C;

[0107] Pre-treatment of coatings. Before spraying, the powder is dispersed by a ball mill at a speed of 60rpm for 20 minutes, and filtered by a filter. The base oil is filtered by 160 mesh, and the middle oil and top oil are filtered by 120 mesh;

[0108] Spraying the bottom layer 301: The sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com