Multi-axis laser cladding anti-gravity deflection ring cone focusing powder feeding nozzle

A laser cladding and anti-gravity technology, applied in metal material coating process, coating and other directions, can solve problems such as gravity segregation of powder feeding nozzle of cladding head, and achieve the effect of life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

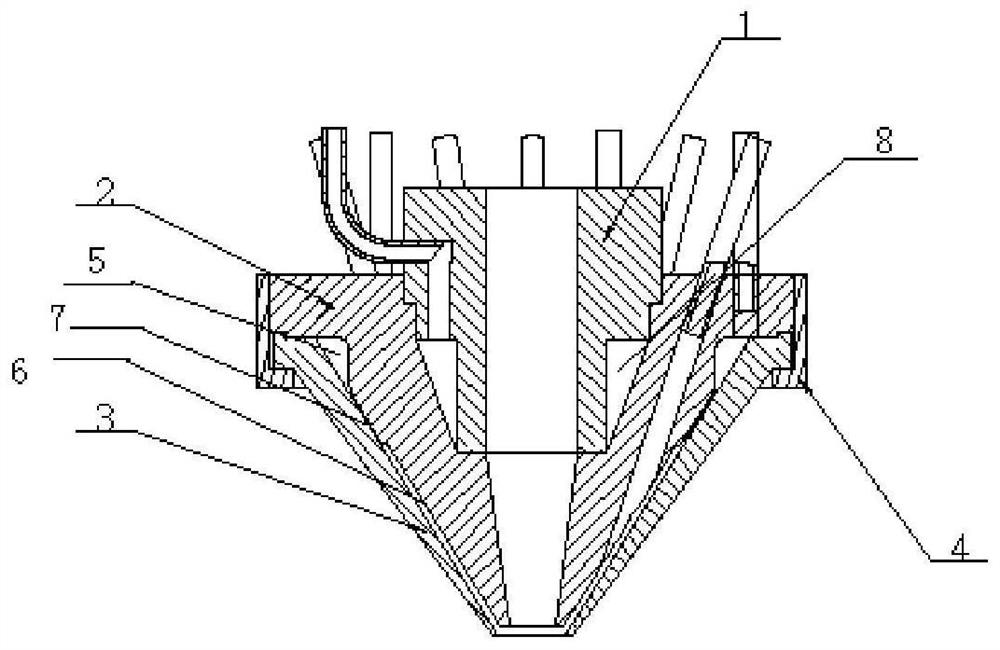

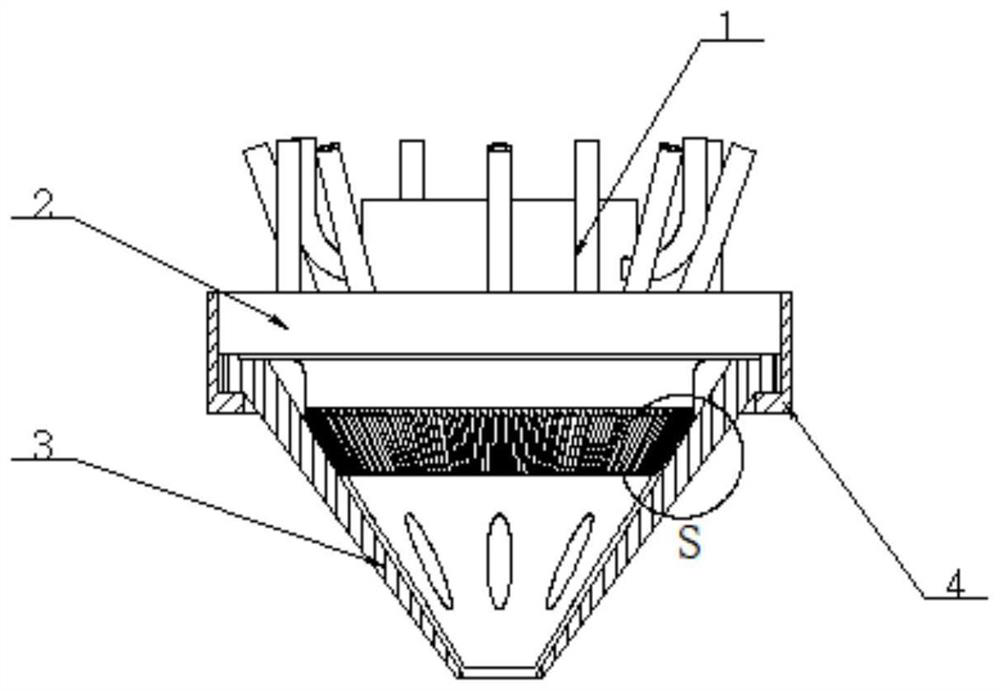

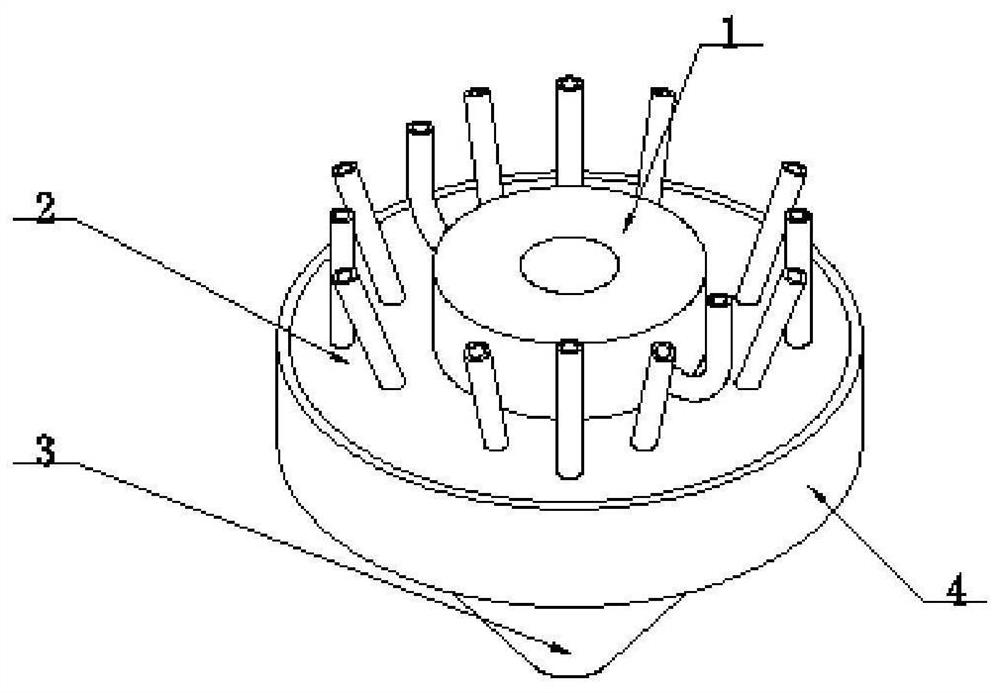

[0075] The multi-axis laser cladding anti-gravity deflection ring cone focusing powder feeding nozzle and laser cladding equipment of the present invention are composed of a water-cooled connection part 1; a uniform gas powder feeding cone core 2; an outer thin converging cone cover 3; a cone cover lock ring 4; The shielding gas annular cavity 5; the powder inverted conical truncated annular seam converging cavity 6; the triangular inverted conical annular equal distribution air channel 7; the cooling water annular cooling structure cavity 8.

[0076] The water-cooling connection 1 is composed of 1-1-1 water inlet pipe, 1-1-2 water outlet pipe, 1-2 water inlet and outlet channel, 1-3 radially outer circular sealing surface, and 1-4 cylindrical cavity that penetrates up and down, Axial circular ring seal outward convex ring surface 1-5, the first inner hole thread 1-6, the first outer circular thread 1-7, the inner half of the annular cooling water channel 1-8, wherein the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com