Method for preparing iron-based amorphous and nanocrystalline coating

An iron-based amorphous and nanocrystalline technology, which is applied in coating, metal material coating process, transportation and packaging, etc., can solve the problems of unstable coating quality and high preparation cost, and achieve low price advantage and low equipment price , The effect of high powder utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

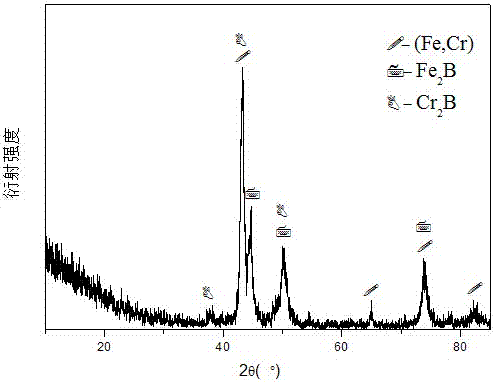

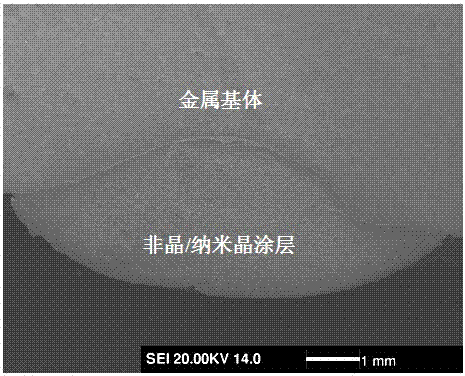

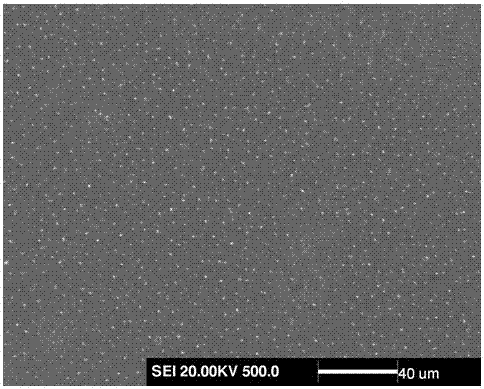

[0012] Specific Embodiment 1: This embodiment describes a method for preparing iron-based amorphous and nanocrystalline coatings, using elemental powdered iron powder, chromium powder, boron powder, silicon powder, and niobium powder as raw materials. Powder, chromium powder, boron powder, silicon powder, and niobium powder have a mass-to-number ratio of (64-2X): 13: (2X+16): 3: 4, where X is 1, 2 or 3, and all elemental powders Put them together with cemented carbide balls into a ball milling tank for ball milling, fully mix, and use argon to protect during the ball milling process; add an organic binder to the homogeneously mixed elemental powder and hard metal balls, and the amount of organic binder added 10g of organic binder is added to every 100g of elemental powder, and the alloy powder is pressed into a rod shape by using a cylindrical mold (YQ32-250t powder forming hydraulic press produced by Nantong Dawo Heavy Industry Machine Tool Co., Ltd.) to obtain a composite mat...

specific Embodiment approach 2

[0013] Specific embodiment two: a method for preparing iron-based amorphous and nanocrystalline coatings described in specific embodiment one, the purity of the iron powder is 99.0%, and the particle size is 325 mesh; the purity of niobium powder is 99.9%, and the particle size is 500 mesh; the purity of boron powder is 99.99%, and the particle size is 180 mesh; the purity of chromium powder is 99.95%, and the particle size is 325 mesh; the purity of silicon powder is 99.95%, and the particle size is 300 mesh.

specific Embodiment approach 3

[0014] Specific embodiment three: a method for preparing iron-based amorphous and nanocrystalline coatings described in specific embodiment one, the balls in the ball mill tank are zirconia, the diameter of the balls is 10mm, and the ball-to-material ratio is 20 : 1, the ball milling speed is 300r / min, the ball milling time is 5h, the protective gas is high-purity argon, and the purity can reach 99.99%.

[0015] Embodiment 4: Embodiment 1 describes a method for preparing iron-based amorphous and nanocrystalline coatings, wherein the organic binder is glue or water glass.

[0016] Embodiment 5: Embodiment 1 describes a method for preparing iron-based amorphous and nanocrystalline coatings, wherein the metal substrate is low-carbon steel, medium-carbon steel or low-alloy steel.

[0017] Embodiment 6: Embodiment 1 describes a method for preparing iron-based amorphous and nanocrystalline coatings, the parameters of the cladding process are: cladding current: 120A, cladding speed: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com