Agricultural centrifugal fertilizer-spreading device

A centrifugal, chemical fertilizer technology, applied in fertilization devices, fertilizer spreaders with centrifugal wheels, applications, etc., can solve the problems of uneven spreading of chemical fertilizers, hurting hands, and inability to change the spreading range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

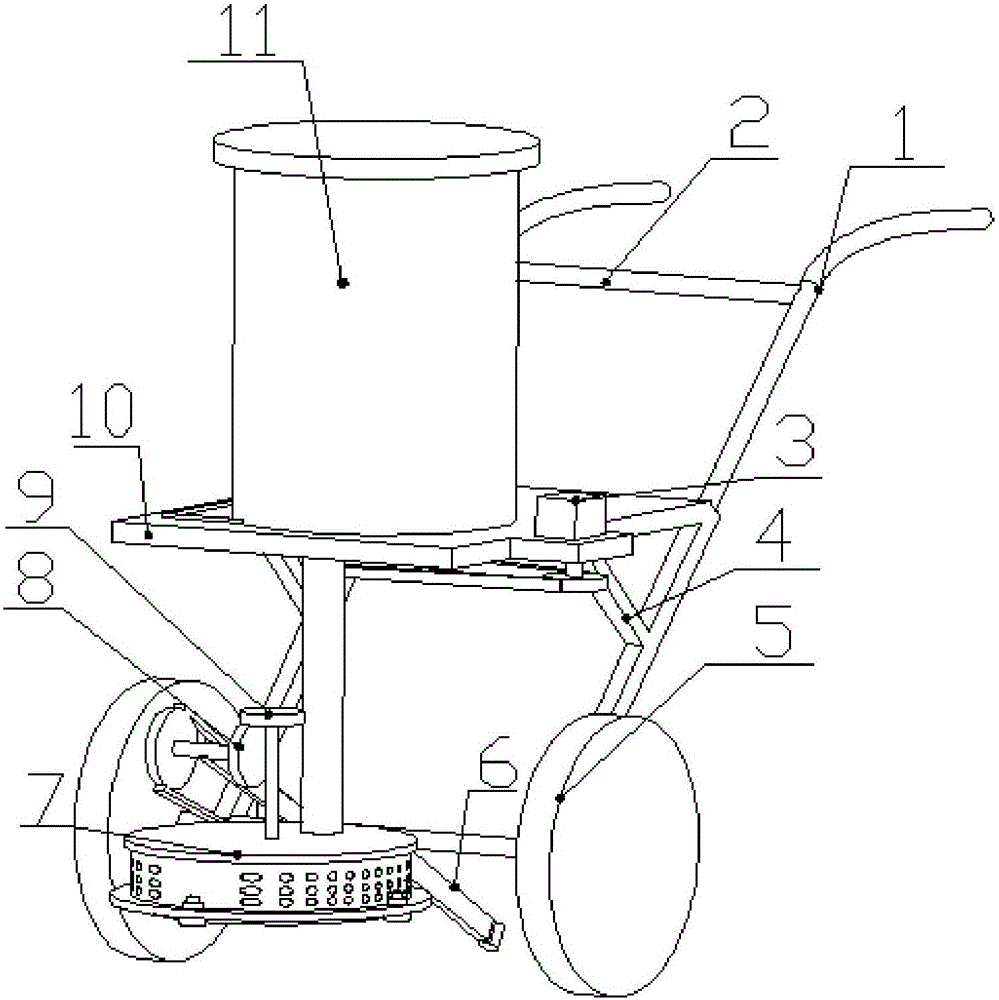

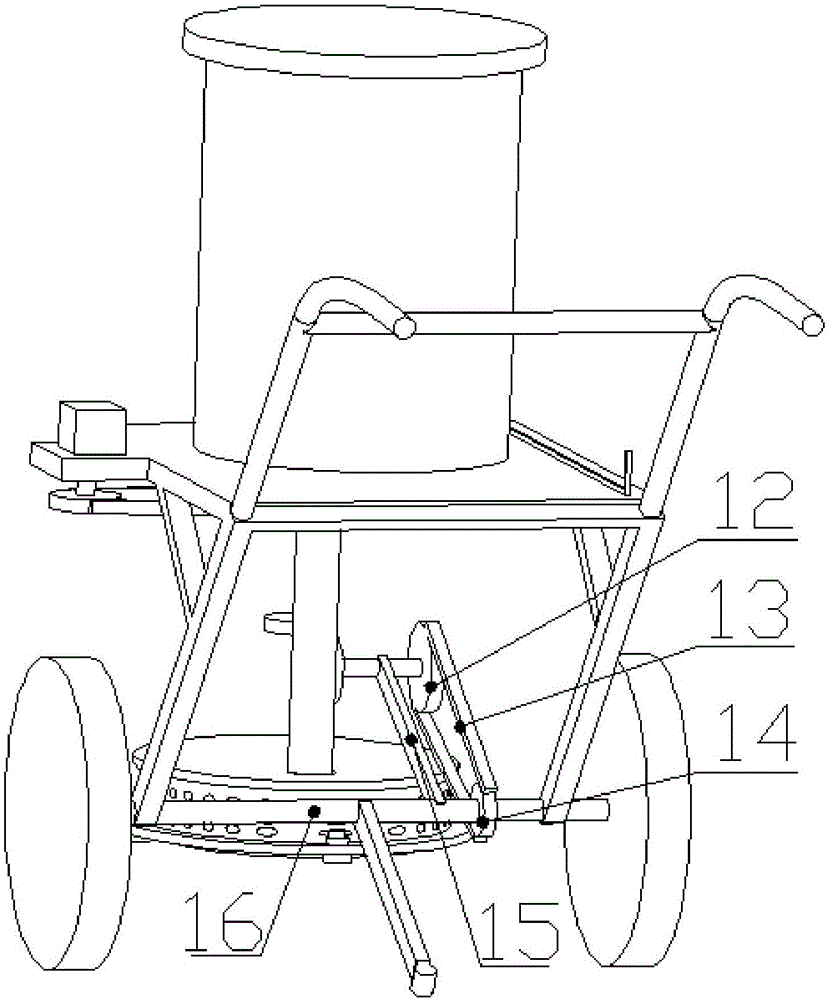

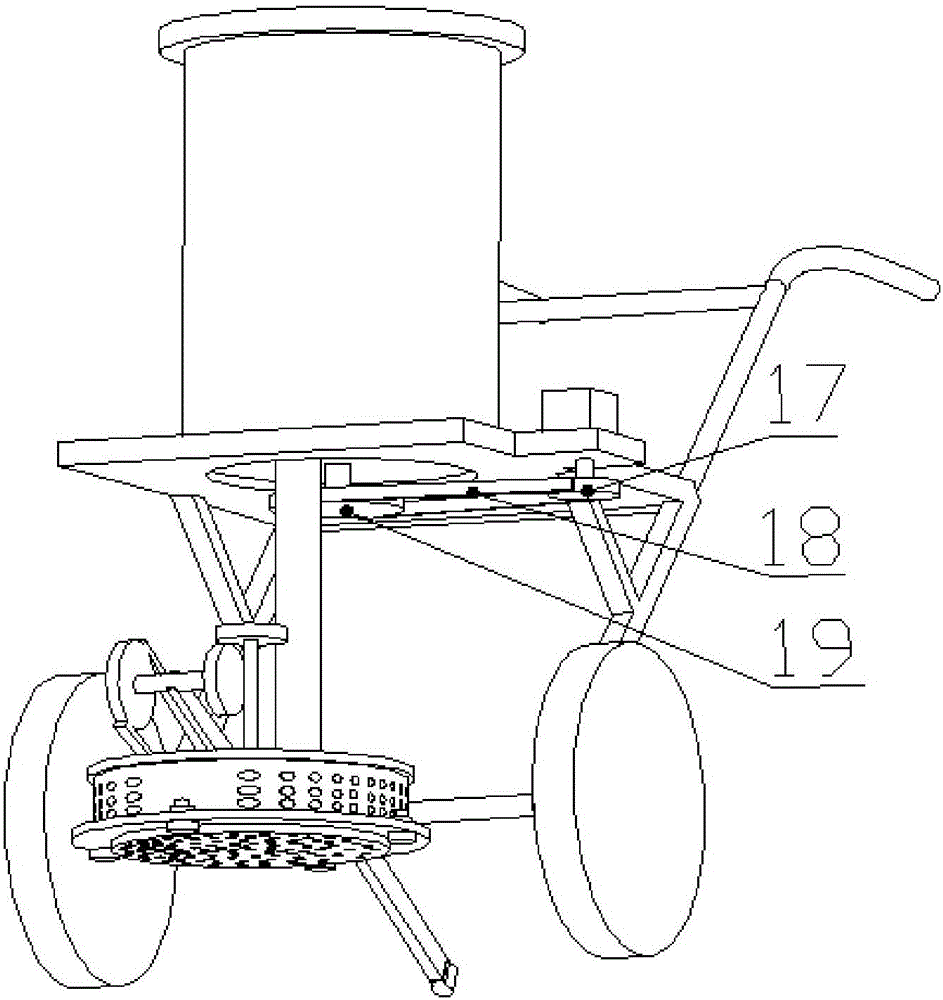

[0009] An agricultural centrifugal fertilizer spreading device is composed of a handlebar 1, a handrail rod 2, a motor 3, ribs 4, wheels 5, a balance bar 6, a secondary storage barrel cover 7, a driving bevel gear 8, Driven bevel gear 9, support plate 10, primary material storage barrel 11, lower large sprocket 12, lower chain 13, lower small sprocket 14, rotating support rod 15, main rotating shaft 16, upper small sprocket 17, upper Chain 18, upper large sprocket 19, rotating shaft 20, connecting plate 21, secondary storage barrel 22, chassis 23, connecting nut 24, primary storage barrel lid 25, spiral sheet 26, feeding pipe 27, lower The material handle 28 and the inner rotating disc 29 are characterized in that: a handrail bar 2 is installed between the two handlebars 1, and the handlebar 1 is fixedly installed on the main rotating shaft 16 through bearings, and on both sides of the main rotating shaft 16 Two wheels 5 are fixedly installed, the balance bar 6 is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com