A ceramic production waste recycling device

A technology for producing waste materials and recycling devices, which is applied in ceramic material production, plastic recycling, recycling technology, etc. It can solve the problems of incomplete crushing of ceramic waste and large labor input, so as to avoid manual crushing, improve crushing quality, and improve grinding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

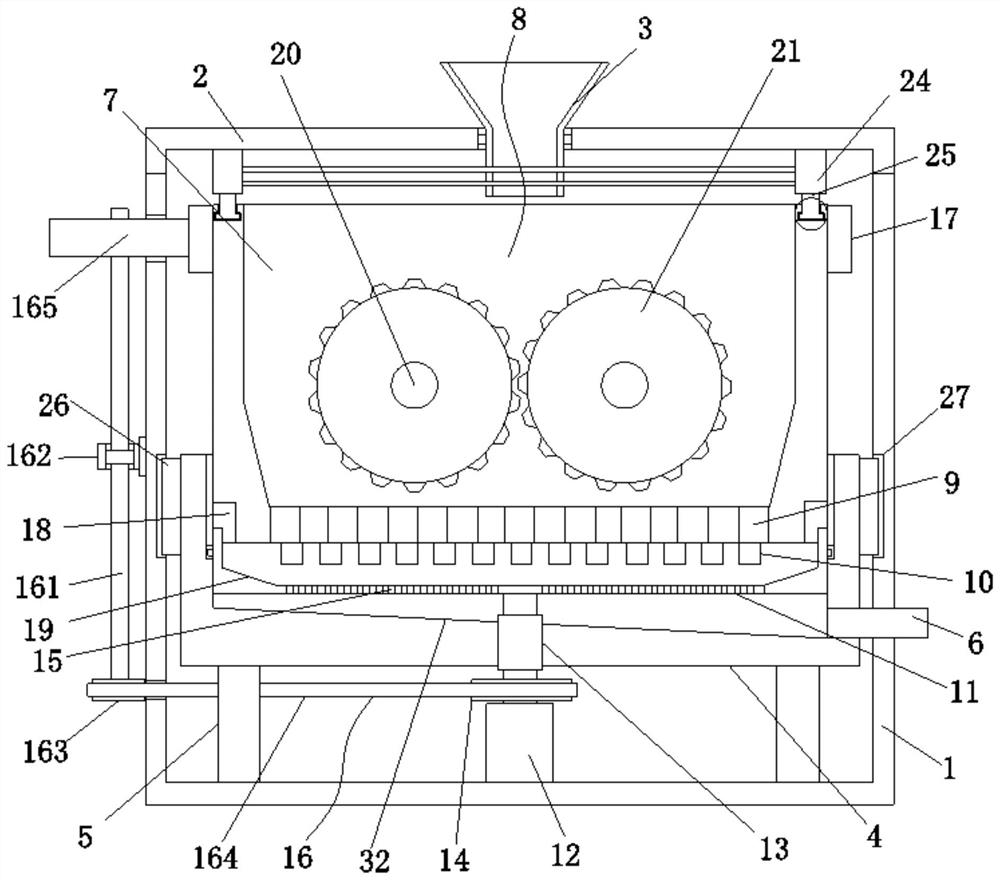

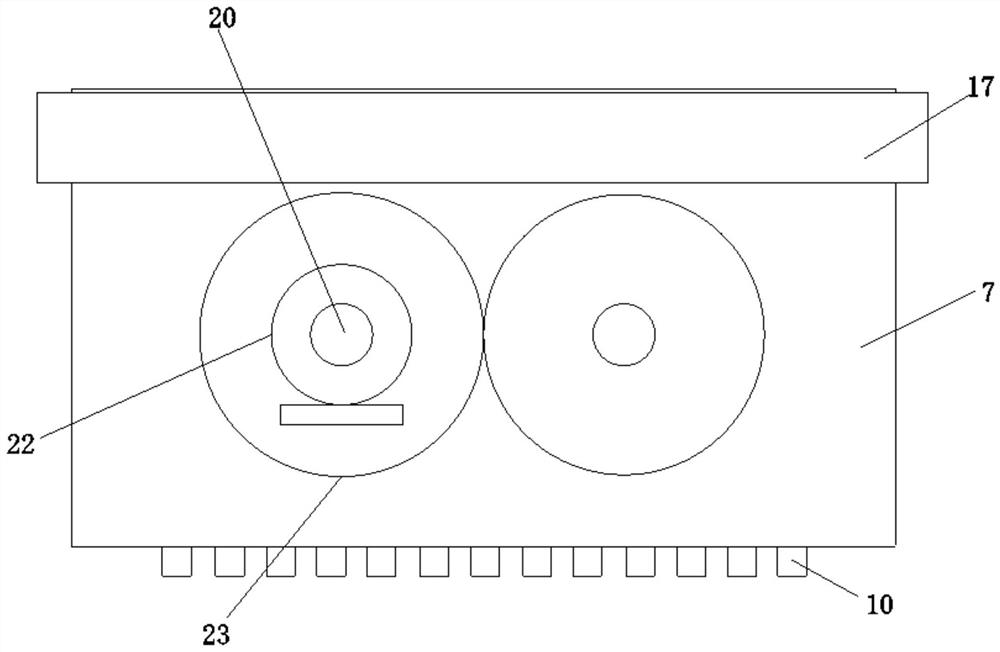

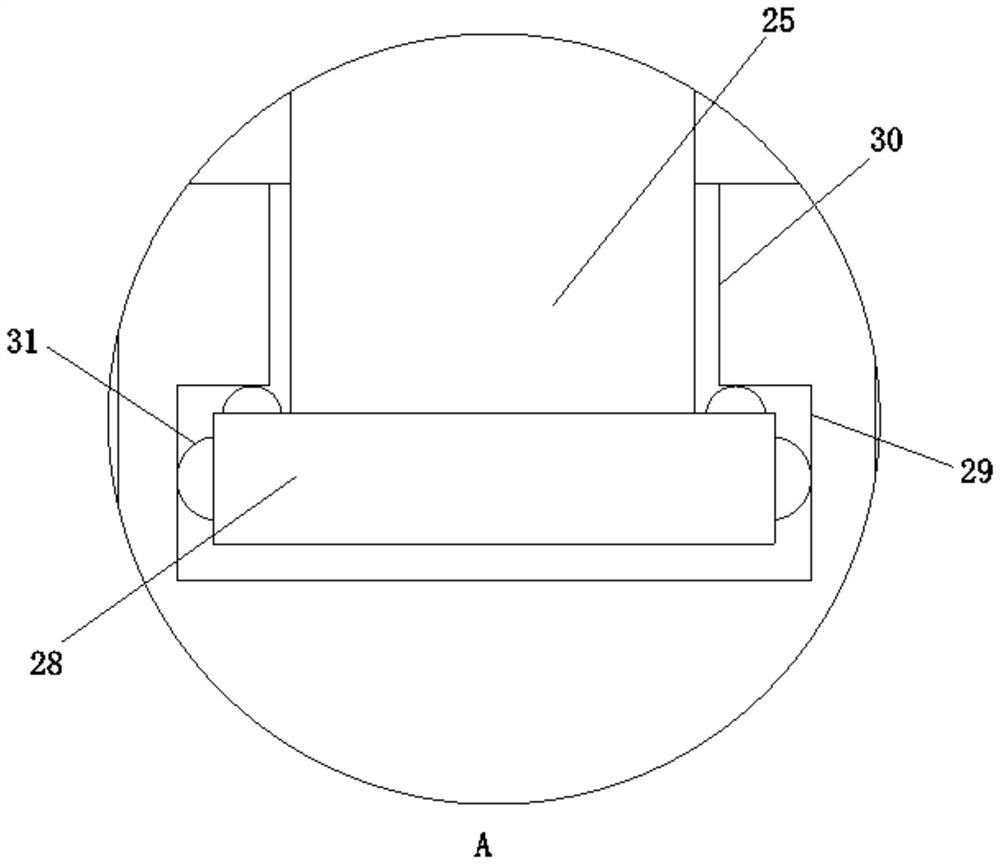

[0031] Example one, by Figure 1 to Figure 6Given, the present invention includes a recovery box body 1 and a recovery box cover 2, the recovery box cover 2 is installed on the top of the recovery box body 1, the top of the recovery box cover 2 is provided with a feeding port 3 in the middle position, and the inside of the recovery box body 1 A discharge box 4 is provided, and the bottom end of the discharge box 4 is provided with a support column 5 located at the inner bottom end of the recovery box 1, and one side of the discharge box 4 is provided with a side wall that runs through the recovery box 1 and extends to the recovery box 1. The discharge pipe 6 outside the box 1, it should be noted here that one end of the discharge pipe 6 is connected to the external suction pump. Through the design of the discharge pipe 6, it is convenient to realize the extraction of the screened waste. The upper part of the body 1 is provided with a crushing box 7 located at the top of the di...

Embodiment 2

[0038] Embodiment 2, on the basis of Embodiment 1, by figure 1 It is given that the aperture of the first screening hole 9 is larger than that of the second screening hole 15, and the inner wall of the grinding seat 11 is provided with a chute 19, thereby realizing the function of double screening.

Embodiment 3

[0039] Embodiment 3, on the basis of Embodiment 1, by figure 1 Given, the inner bottom end of the discharge box 4 is provided with a material guide plate 32, the output shaft of the motor one 12 and the bottom end of the discharge box 4 are connected by a bearing sleeve 13, and the outer wall of the discharge box 4 is symmetrically provided with The stabilizer 26 , the inner wall of the recovery box 1 is provided with a stabilization groove 27 that is clamped with the stabilizer 26 , so as to control the stability of the discharge box 4 and avoid displacement of the discharge box 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com