Cloth flaw detection control system on cloth spreading machine

A defect detection and control system technology, applied in the direction of spreading thin soft materials, analyzing materials, measuring devices, etc., can solve the problems of high labor intensity for workers, missing inspections, inaccurate inspections, etc., to improve spreading efficiency, Guarantee the pass rate and avoid the effect of high error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

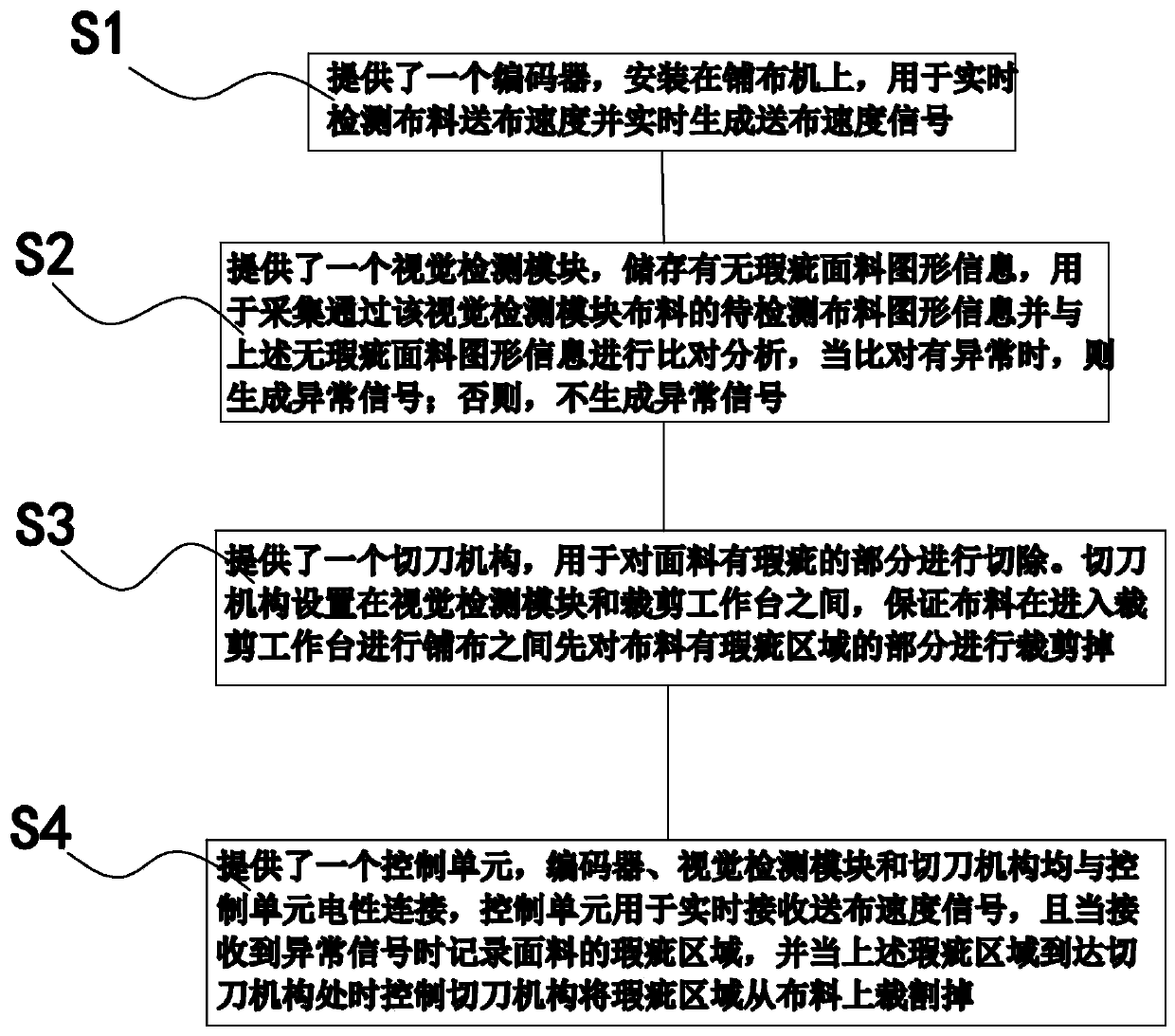

[0034] Such as figure 1 As shown, the cloth defect detection and control method on the spreading machine includes the following steps:

[0035] S1. An encoder is provided, which is installed on the cloth spreading machine, and is used to detect the cloth feeding speed of the cloth 1 in real time and generate a cloth feeding speed signal in real time.

[0036] Generally, an encoder is installed on the cloth spreading machine to detect the cloth feeding speed. Since the cloth has different materials, the requirements for the cloth feeding speed are different. The cloth of the same material is not always uniform during the whole cloth feeding process. , the speed is variable. The encoder can detect the current feeding speed of the cloth in real time to the control system of the spreading machine, so that the spreading machine can understand the current feeding speed of the cloth in real time for more accurate control. The detection principle is the existing technology and will n...

Embodiment 2

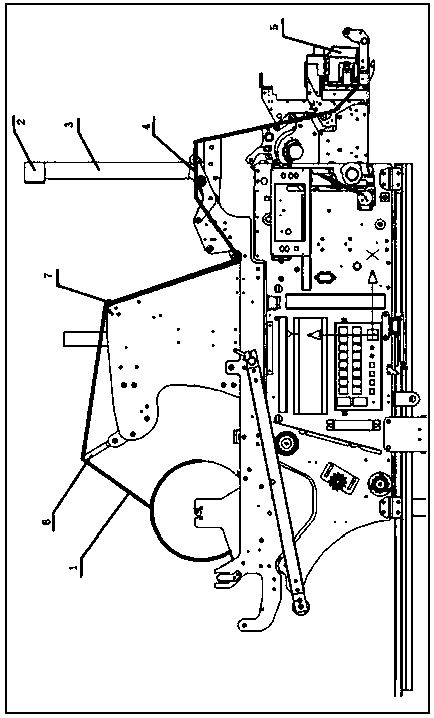

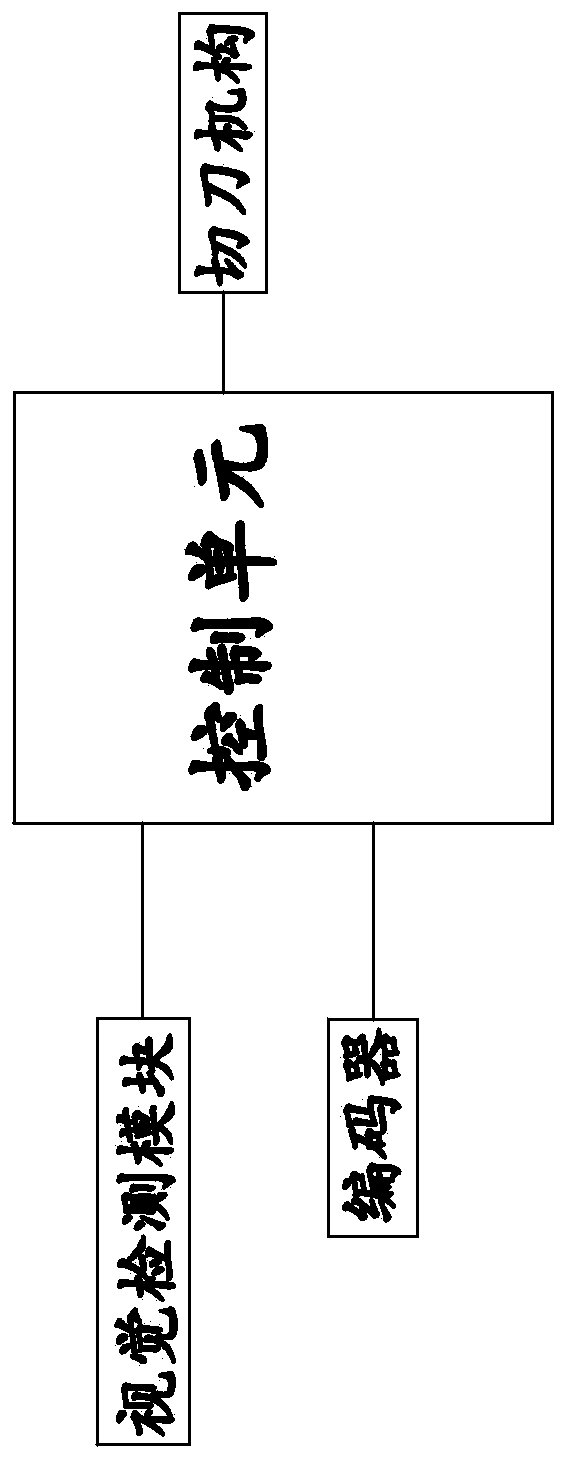

[0048] Such as figure 2 and 3 As shown, the cloth spreader includes a spreader rod 6 and a cloth feed rod 7. The blue line in the figure is the cloth. The cloth defect detection and control system on the cloth spreader includes:

[0049] The encoder is installed on the spreading machine and is used to detect the cloth feeding speed in real time and generate a cloth feeding speed signal in real time;

[0050] The visual inspection module stores the graphic information of the fabric with or without defects, and is used to collect the graphic information of the fabric to be inspected through the visual inspection module and compare and analyze it with the graphic information of the above-mentioned flawless fabric. When there is an abnormality in the comparison, an abnormality is generated signal; otherwise, no exception signal is generated;

[0051] The cutter mechanism 5 is used to cut off the defective part of the fabric;

[0052] The control unit, the encoder, the visual d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com