High precision laser cutting device

A technology of laser cutting and laser cutting head, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of rapid tool passivation, high fuel consumption, rough cutting surface, etc., and achieve the effect of fast and accurate cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

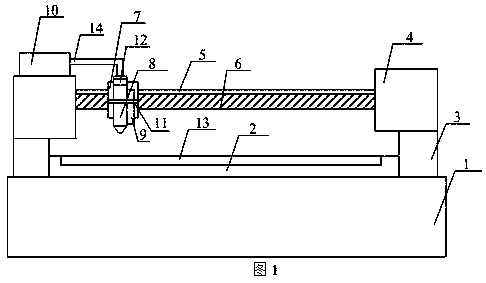

[0013] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0014] Such as figure 1 As shown, a high-precision laser cutting device includes: a workbench 2 is installed on the frame 1, and transmission belts 3 are installed on both sides of the workbench 2, so that the laser cutting head 8 can move horizontally along the Z axis, and the transmission belt 3 is installed Limiting column 4, limiting column 4 is connected by rail beam 5, rail groove 6 is installed on rail beam 5, rail car 7 is installed on rail groove 6, laser cutting head 8 and infrared positioning mechanism 9 are installed on rail car 7 , so that the laser cutting head 8 can move horizontally along the Y axis, and the laser emitter 10 is installed on the limit post 4 on one side.

[0015] The infrared positioning mechanism 9 and the laser cutting head 8 are fixed on the rail car 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com