Steel bar cutting machine

A steel bar cutting machine and rotating motor technology, applied in the field of cutting machines, can solve the problems of loose locking, clogged cutting head, cutting position deviation, etc., and achieve the effect of simple and reasonable structure, accurate and fast cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

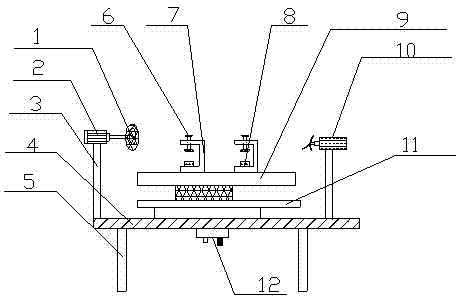

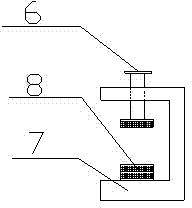

[0011] Such as figure 1 Shown, a kind of steel bar cutting machine, it comprises cutting device, workbench 4 and the slide rail 9 that is arranged on workbench 4, guide rail 11, and described cutting device is arranged on described workbench 4 by support bar 3 The rotary motor 2 and the grinding wheel 1 connected to the output end of the rotary motor 2 are composed; the slide rail 9 realizes the sliding displacement through the slider provided on the bottom surface of the slide rail 9 and the guide rail 11, and the mutual cooperation between the slide rail, the slide block and the guide rail , the sliding movement of the steel bar to be cut is realized, which is convenient for cutting in the next step; an electric fan 10 is arranged on the other side of the workbench 4 relative to the rotating motor 2, and the electric fan 10 is set by a support rod 3 On the workbench 4, the electric fan provided can not only blow off the residue generated when cutting the steel bar, but also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com