Powder spreading device and additive manufacturing device

A powder spreading device and additive manufacturing technology, which is applied in the field of 3D printing, can solve the problems of low powder spreading efficiency and achieve the effect of avoiding waste and improving powder spreading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

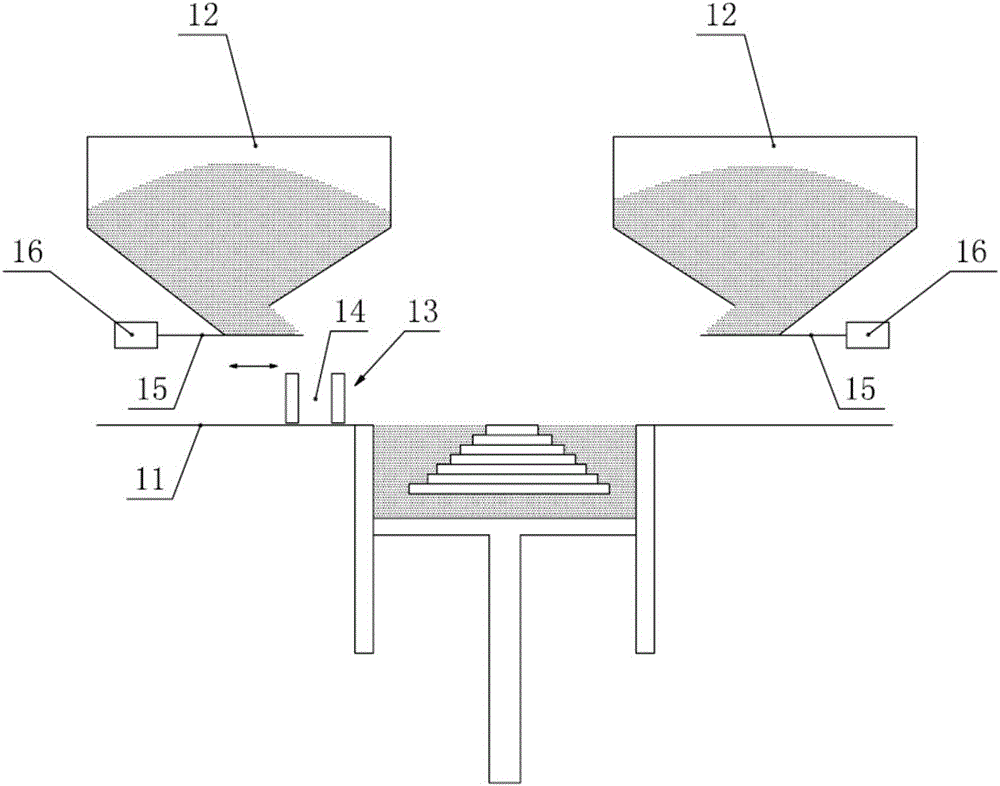

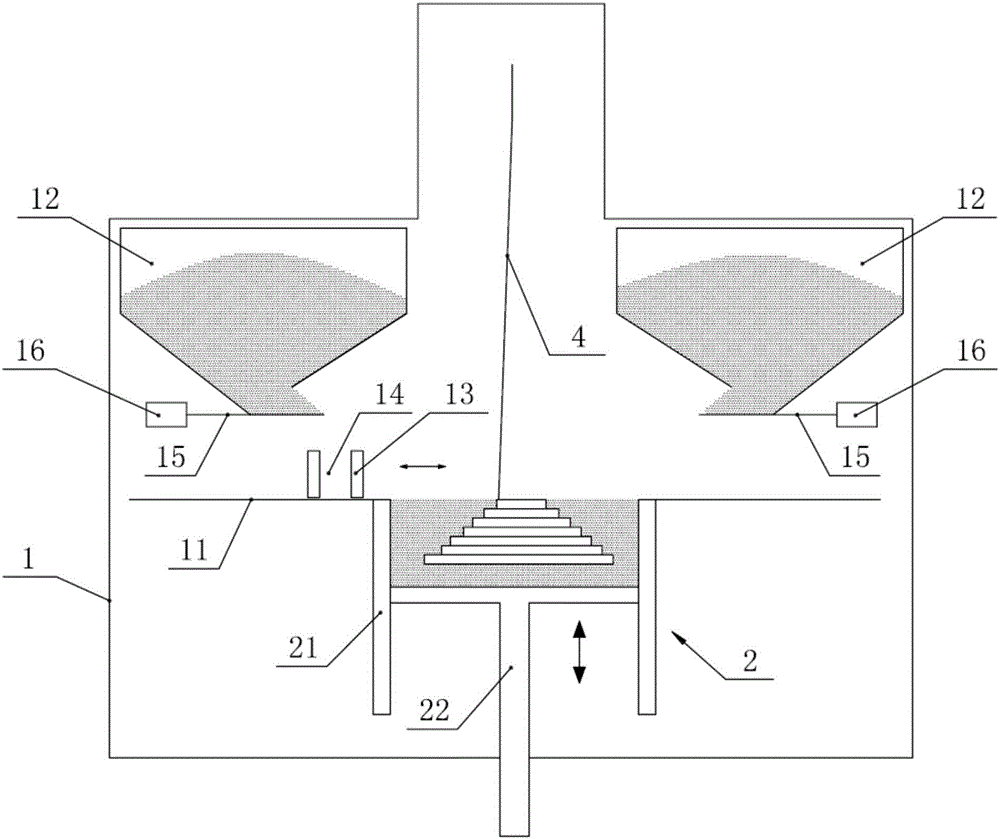

[0031] This embodiment provides a powder spreading device, such as figure 1 As shown, the powder spreading device includes a powder spreading platform 11, a hopper 12, a powder conveying mechanism (not shown) and a scraper 13, wherein powder material is placed in the hopper 12, which is arranged above the powder spreading platform 11 both sides, The powder conveying mechanism is located below the hopper 12 and connected to the hopper 12 for conveying the powder material in the hopper 12 to the powder spreading platform 11 . The scraper 13 is arranged on the powder spreading platform 11 and can move along the horizontal direction for laying the powder material.

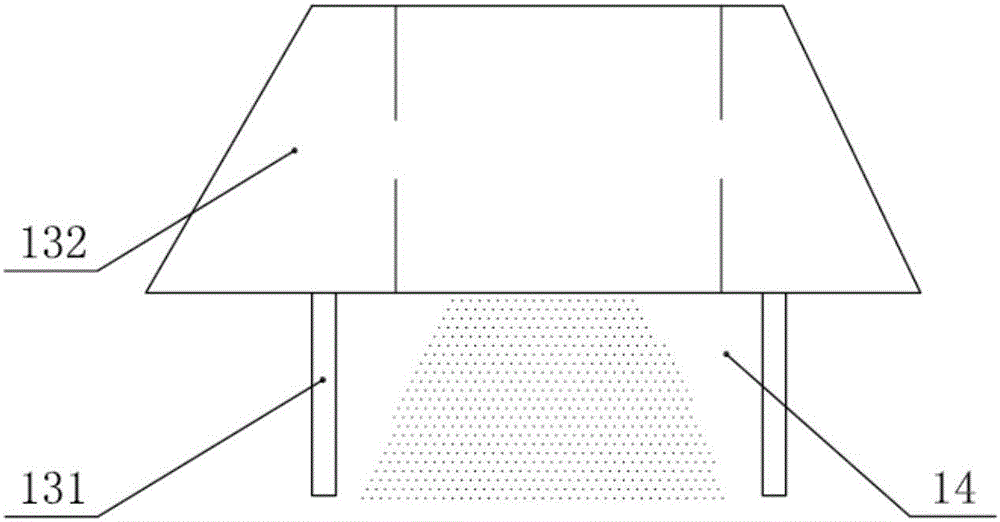

[0032] In this example, refer to figure 1 and figure 2 Above-mentioned scraper 13 is arranged vertically, and it comprises two groups of blades 131 that are vertically and parallelly arranged, and the connection structure 132 that connects two groups of blades 131, is formed with placement cavity 14 between above-me...

Embodiment 2

[0052] In this embodiment, a detection device 3 is added on the basis of the additive manufacturing device in Embodiment 1, specifically, as Figure 8 As shown, the detection device 3 is arranged in the forming chamber 1 and symmetrically arranged on both sides of the forming cylinder 2 . In this embodiment, a number of through holes 111 located on both sides of the forming cylinder 2 are opened on the powder spreading platform 11. When the scraper 13 lays the powder material, part of the powder material will fall into the through hole 111, and the detection device 3 will detect the falling. The amount of powder material entering the through hole 111 is detected, and the amount of powder material to be transported next time is adjusted according to the detected result, so as to avoid waste of powder material.

[0053] Specifically, the detection device 3 includes a pipeline 31 with one end connected to the through hole 111 , a recovery box 32 located at the other end of the pi...

Embodiment 3

[0057] The difference between this embodiment and Embodiment 2 is that the structure of the detection device 3 is different, specifically, refer to Figure 9 , the detection device 3 of this embodiment includes a pipeline 31 connected to the through hole 111 at one end, a recovery box 32 located at the other end of the pipeline 31 , and a proximity switch 33 a located on the pipeline 31 . In this embodiment, the detection of the amount of powder material is carried out through the proximity switch 33a. Specifically, when the powder material passes through the pipeline 31, it will block the proximity switch 33a, and the proximity switch 33a will generate a pulse signal, and the amount of powder material falling into the through hole 111 The larger the value is, the longer the time of flowing through the pipeline 31 is, the longer the time of blocking the proximity switch 33a is, and the larger the width of the pulse is.

[0058] The detection process of the above-mentioned dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com