Tracer particle sowing device for two-phase flow field PIV measurement and operation method

A technology of tracer particles and operation methods, which is applied in the directions of measuring devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve problems such as measurement result deviation and wrong measurement results, and achieve easy processing, improve spreading efficiency, and solve Effects of Blending and Interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

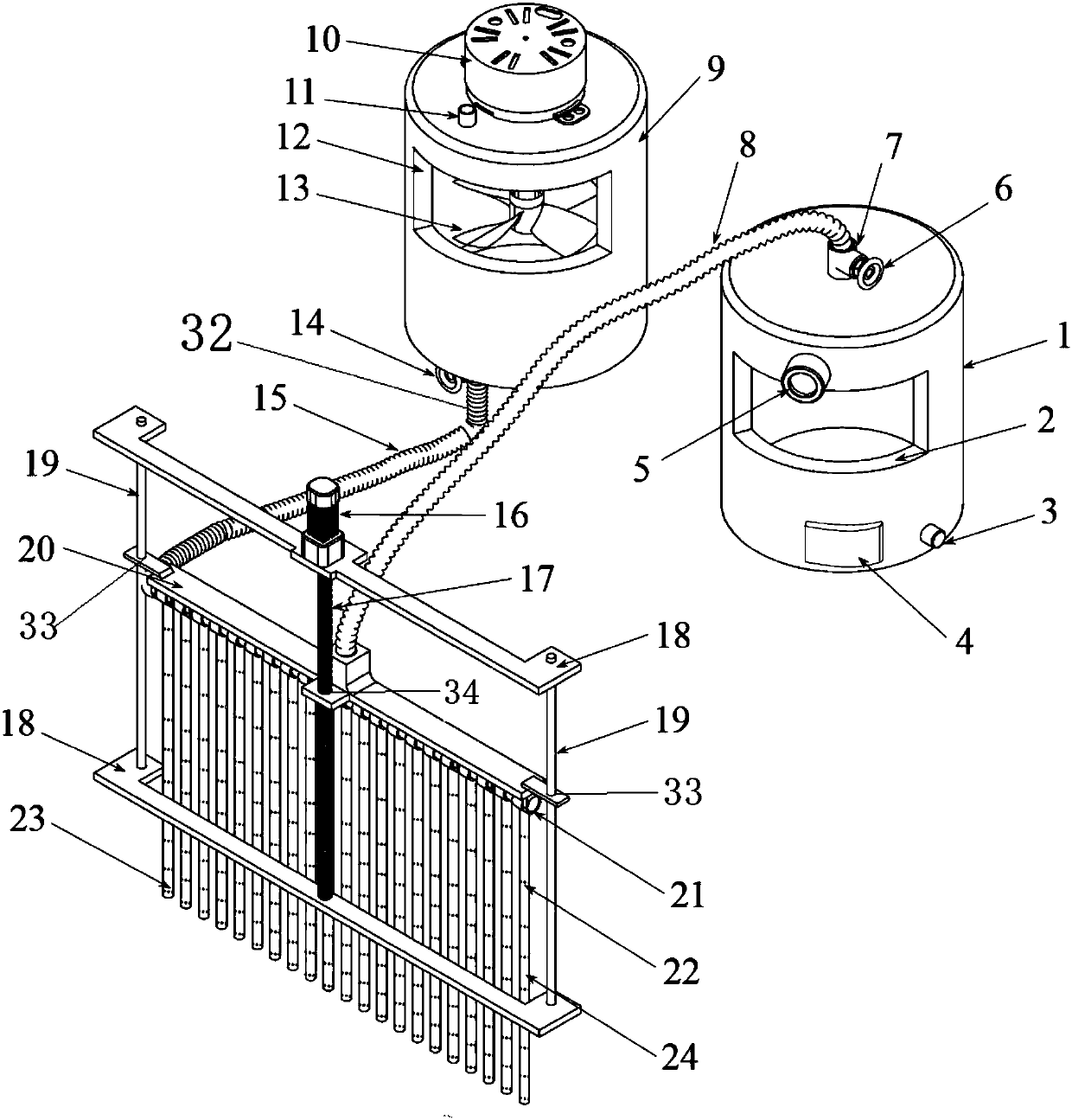

[0044] When used for the PIV measurement of two-phase flow field, a certain amount of tracer particles are injected into the cylindrical pressure-holding tank 1 and the tank 9 with a mixer through the funnel-shaped guide pipe from the air inlet 3 and the water inlet 11 respectively. At this time, both the first valve 6 and the second valve 14 are in the closed state. Remove the funnel-shaped guide pipe then, and air and water are sent into the tank body from the air inlet 3 and the water inlet 11 respectively by the air compressor and the water pump. When the pressure value shown by the pressure gauge 5 on the cylindrical pressure-holding tank 1 reaches the predetermined pressure, remove the air compressor and close the air inlet 3; when the water level in the tank 9 with the mixer reaches the predetermined water level, remove the The water pump closes the water inlet, and opens the stirring device 13 for stirring. After a certain period of time, the first motor 10 is turned ...

Embodiment 2

[0046] When used in a single-phase flow field, only one corresponding tank body is used in Embodiment 1, and the other tank is closed.

[0047] The given examples are given only to aid in the illustration of the invention and are not intended to be limiting.

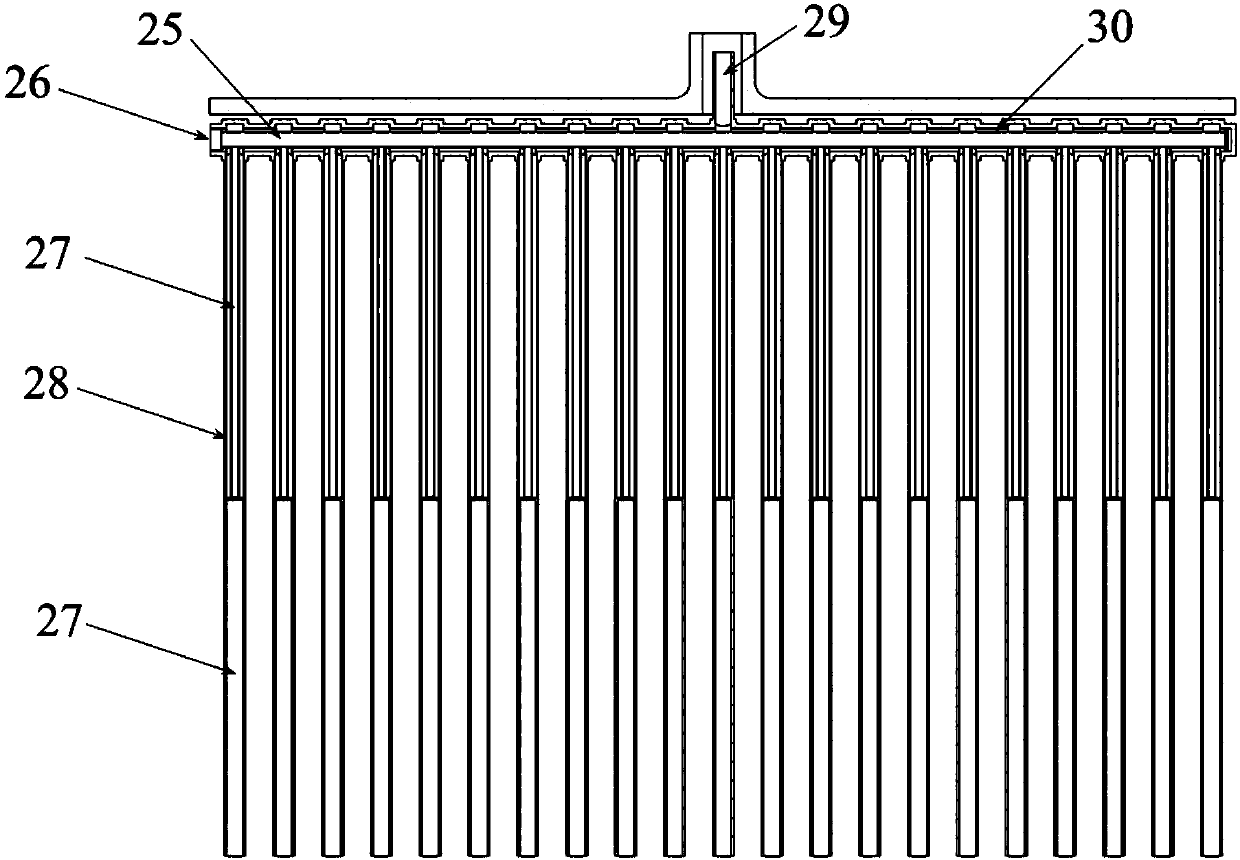

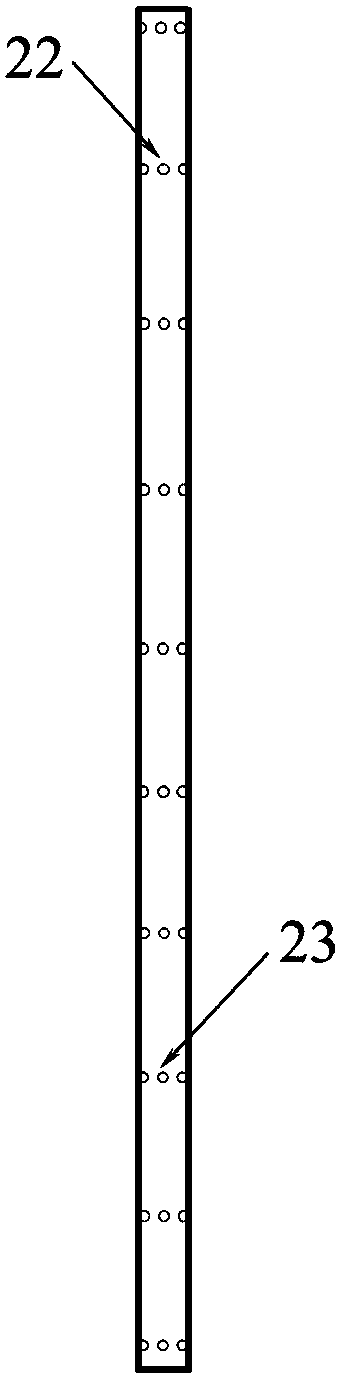

[0048] Compared with the prior art, the tank premixing device adopted in the present invention can premix the tracer particles in the gas phase and the liquid phase synchronously, which greatly saves time and cost. The cylindrical pressure-holding tank body can realize the pressure-holding delivery of particles, and the structure is simple, safe and reliable. The liftable particle releaser realizes the free lifting of the particle releaser through the simple structure of the motor and the screw rod, ensuring that the particles can be delivered to the measurement area quickly and accurately. The special pipeline structure adopted by the particle releaser effectively solves the problem of mutual mixing and interference of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com