Mechanical contact-type bidirectional switching powder laying system based on powder bed

A technology of mechanical contact and powder laying, which is applied in the improvement of process efficiency, additive manufacturing, additive processing, etc., can solve the problems of increasing the weight of the powder laying trolley, insufficient mechanical stability, and increasing energy consumption, so as to reduce manufacturing Cost, accurate and high-efficiency reversing powder coating, reducing the effect of redundant actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

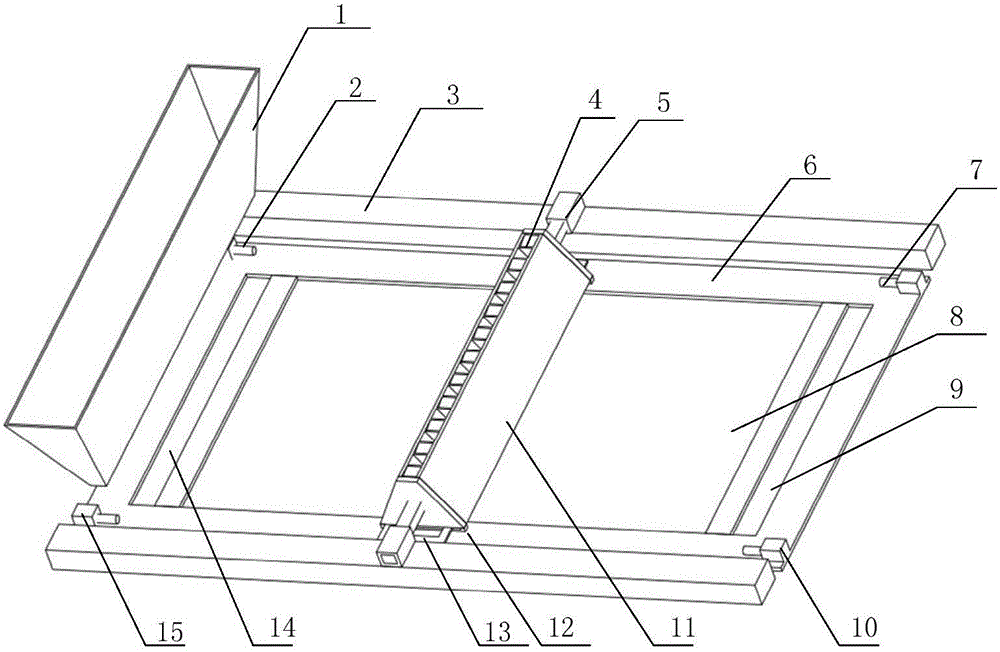

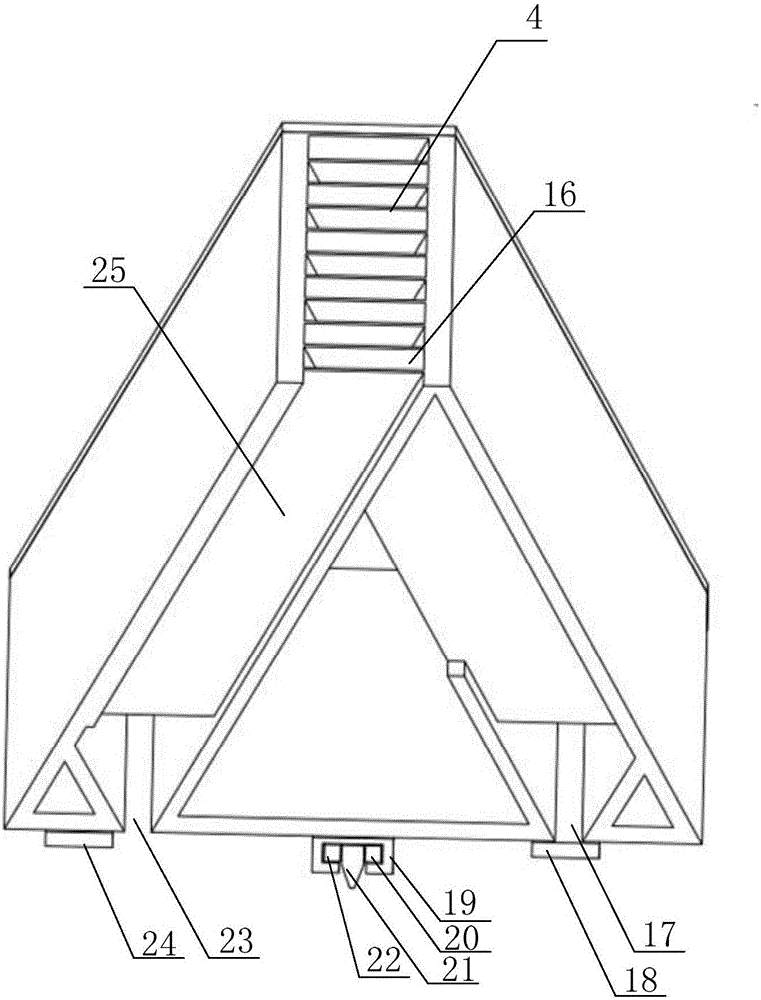

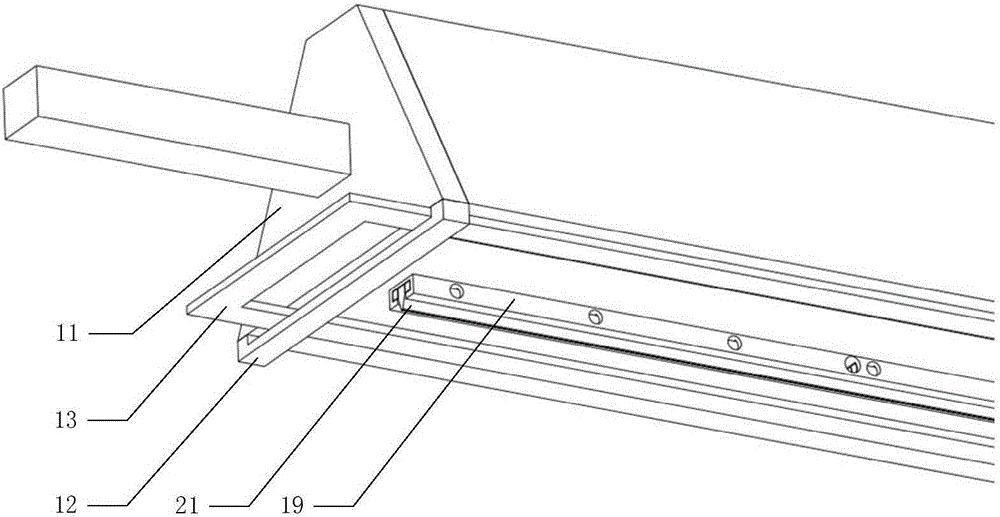

[0029] Such as Figure 1-Figure 4 As shown, the present embodiment is based on a mechanical contact type two-way switching powder spreading system of a powder bed, including a forming horizontal plate 6, a linear guide rail 3 is provided on the forming horizontal plate 6, and a two-way switching powder spreading system is erected on the linear guide rail 3 The main body 11, the left and right sides of the powder spreading main body 11 are provided with linear motor sliders 5, and the two-way switching powder spreading main body 11 includes a powder spreading device powder inlet 4, a limit plate 12, a contact back-shaped sealing plate 13, Powder spreading feeding port and scraper 21, the powder feeding device powder inlet 4 is arranged above the two-way switching powder spreading main body 11, and the powder spreading feeding port and scraper 21 are arranged on the top of the two-way switching powder spreading main body 11 Below, the limit plate 12 is located on both sides belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com