An impact testing device

A technology of testing device and impact force, which is applied in the direction of impact test, measuring device, force/torque/power measuring instrument, etc., can solve the problems of low precision, high cost, and difficult realization, so as to prevent excessive instantaneous displacement and reduce Small amplitude and time, reducing the effect of pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

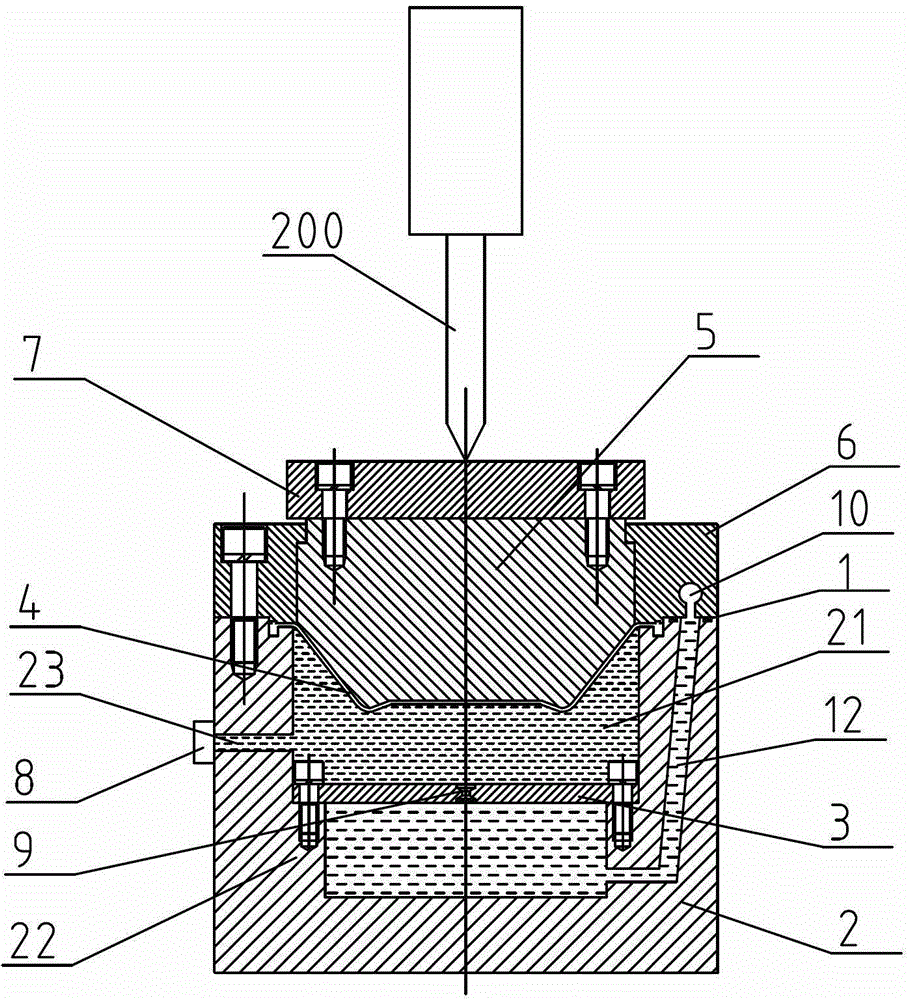

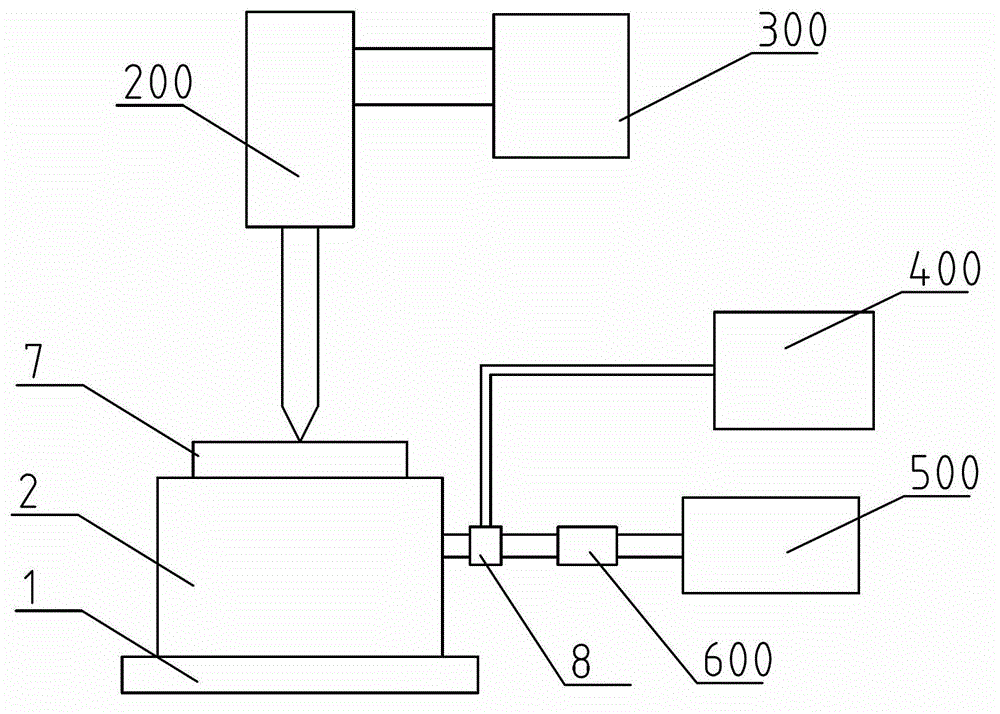

[0024] Embodiment 1, figure 1 A device for testing impact force is given, which includes a cylinder body 2, a cavity is provided in the cylinder body 2, and a damping orifice plate 3 fixed by bolts is arranged in the cavity, and the damping orifice plate 3 divides the cavity into two parts. Chamber I21 and chamber II22 (the upper chamber is chamber I21, and the lower chamber is chamber II22). The damping orifice 3 is provided with at least one damping hole 9, such as figure 1 or image 3 As shown, what is adopted in this embodiment is a damping hole 9 . The upper end of the chamber I21 is fixed with a rubber cup 4, and the chamber I21 and the chamber II22 are sealed through the rubber cup 4 (that is, the oil in the chamber I21 and the chamber II22 can be sealed through the rubber cup 4, so that the chamber I21 And the oil in the chamber II22 will not overflow). A piston 5 is arranged above the rubber cup 4; an upper cover 6 (that is, an annular upper cover 6) that matches ...

Embodiment 2

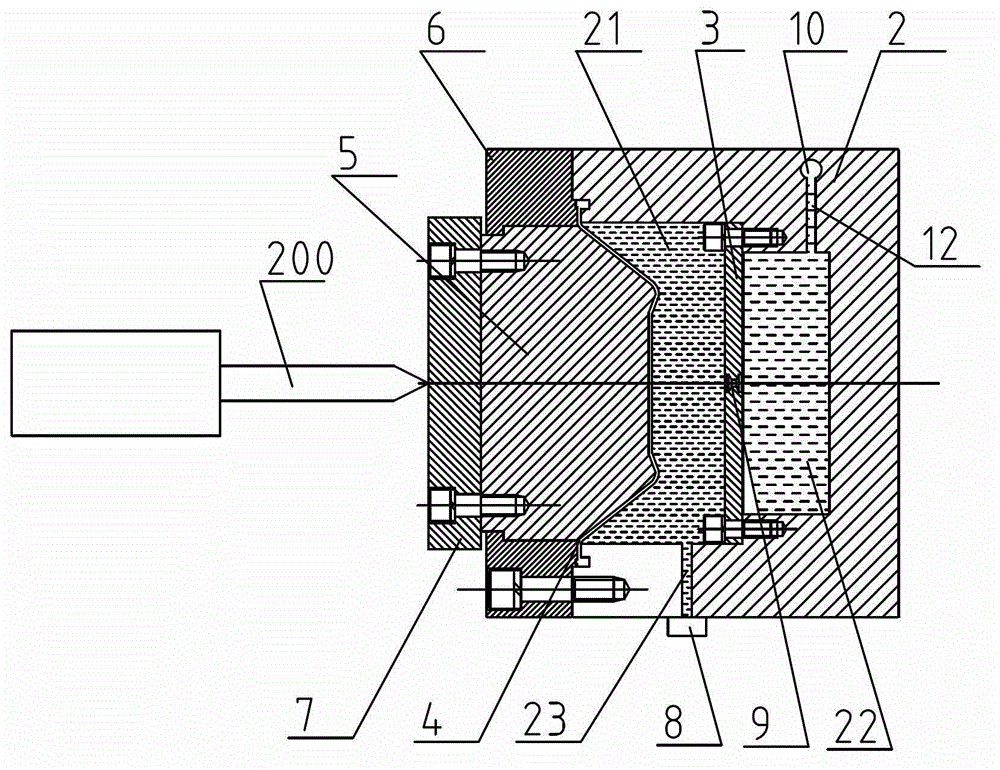

[0038] For some impact devices that strike in the horizontal direction, the present invention proposes Embodiment 2;

[0039] Embodiment 2, image 3 A kind of impact force testing device is provided, and the concrete structure except air bubble 10, oil channel 12 and sealing device 1 is exactly the same as embodiment 1; image 3 As shown, when the impact force is applied to the side of the device, the bubble 10 is still located at the top of an impact test device of the present invention, and the gas in the bubble 10 will not enter the oil. The specific implementation process of this embodiment is exactly the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com