Two-dimensional motion platform

A two-dimensional motion platform, motion platform technology, applied in electric components, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problem of affecting the positioning accuracy and stable speed of the motion platform, the vibration of the motion platform base, and the decrease in the positioning accuracy of the motion platform. and other problems, to achieve the effects of improving positioning accuracy, smoothing fluctuations, and shortening vibration time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

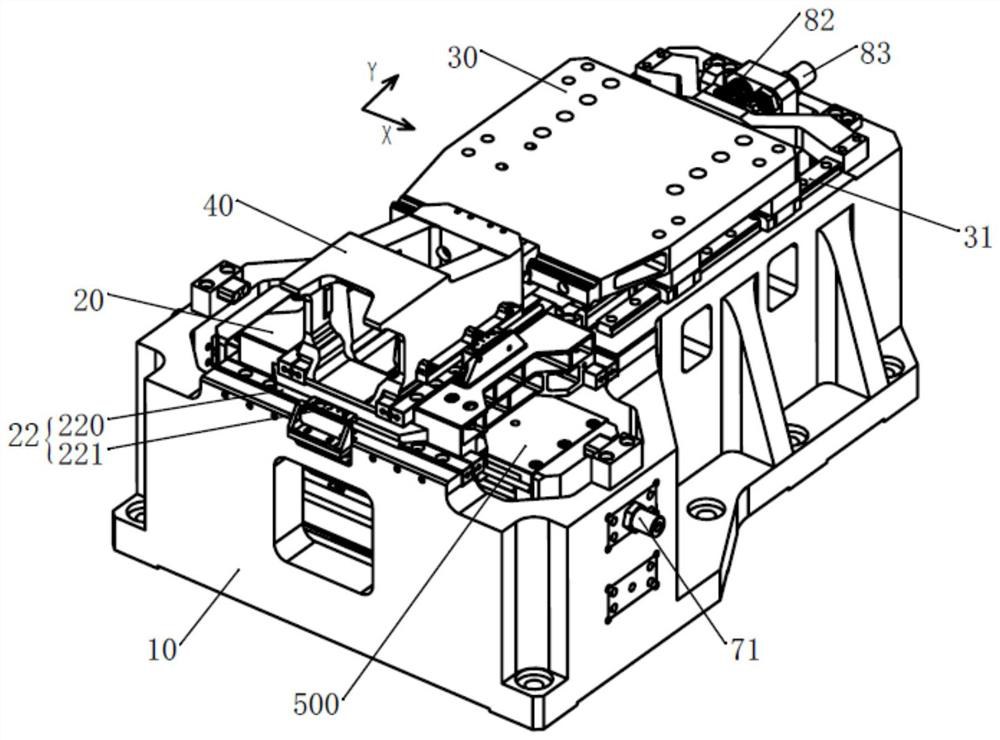

[0048] as Figures 1 to 5 As shown in the figure, in an embodiment provided by the invention, a two-dimensional motion platform is provided, including:

[0049] Base 10;

[0050] The x-direction motion platform 20 is installed on the base 10 through the x-direction guide rail 21 and can move linearly in the x-direction relative to the base 10;

[0051] The y-direction moving platform 30 is installed on the base 10 through the y-direction guide rail 31 and can move linearly in the y-direction relative to the base 10;

[0052] The working motion platform 40 is installed on the x-direction motion platform 20 through the motion platform guide rail 41 and connected with the y-direction motion platform 30 through the decoupling guide rail 32. The working motion platform 40 can make linear movement in the XY plane driven by the x-direction motion platform 20 and the y-direction motion platform 30;

[0053] The x-direction driving linear motor 50 is used to drive the x-direction moving pla...

Embodiment 2

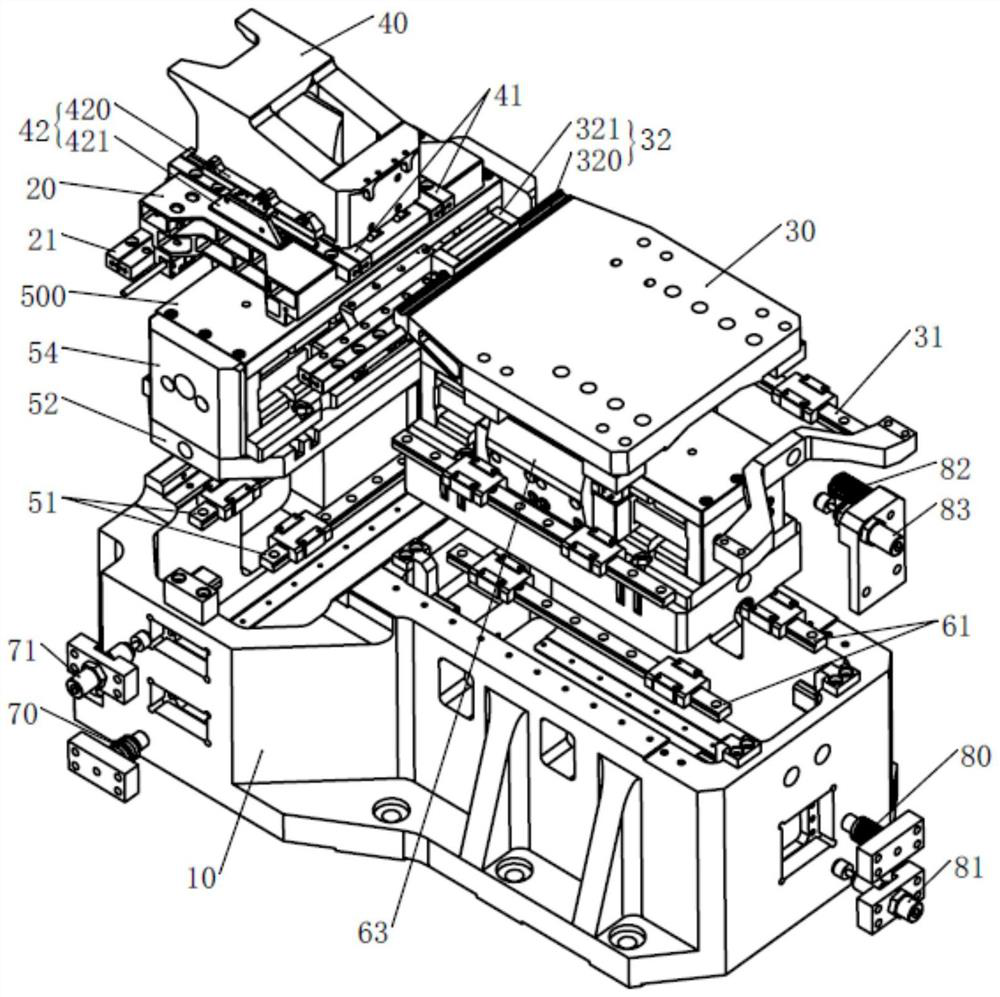

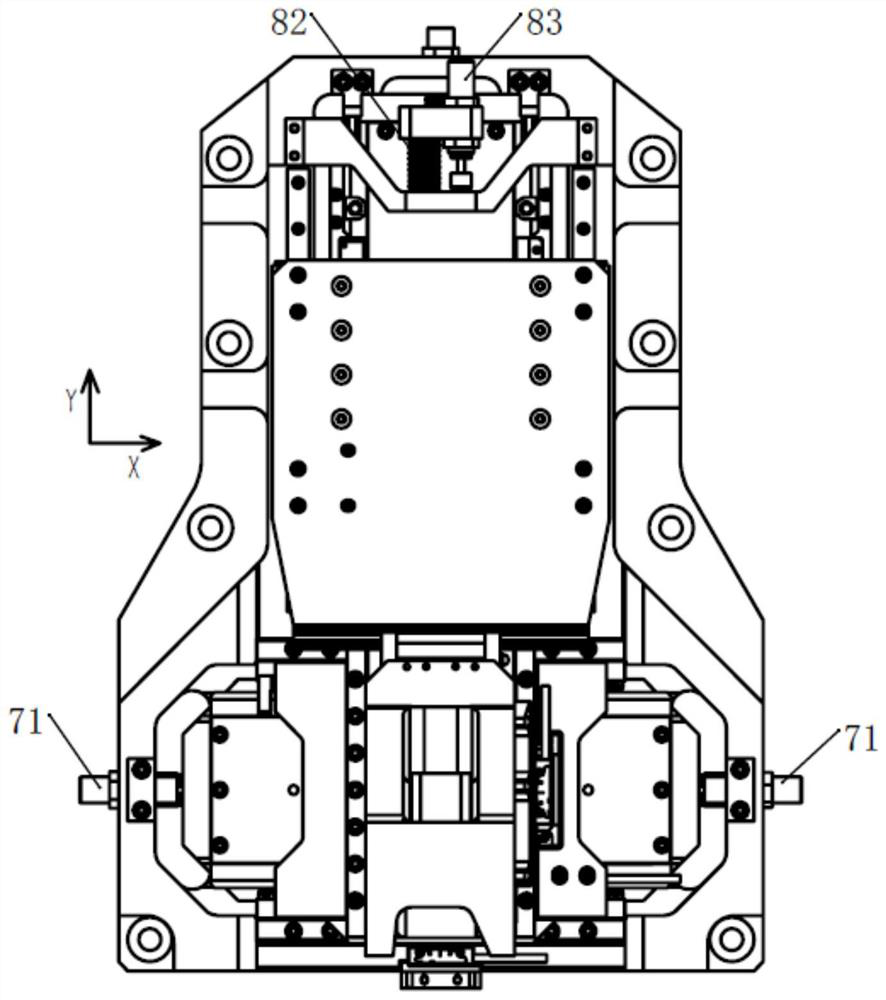

[0075] as Figures 6 to 11 As shown in the figure, in an embodiment provided by the invention, a two-dimensional motion platform is provided, including:

[0076] Base 10;

[0077] The x-direction motion platform 20 is installed on the base 10 through the x-direction guide rail 21 and can move linearly in the x-direction relative to the base 10;

[0078]The y-direction moving platform 30 is installed on the base 10 through the y-direction guide rail 31 and can move linearly in the y-direction relative to the base 10;

[0079] The working motion platform 40 is installed on the x-direction motion platform 20 through the motion platform guide rail 41 and connected with the y-direction motion platform 30 through the decoupling guide rail 32. The working motion platform 40 can move linearly in the XY plane driven by the x-direction motion platform 20 and the y-direction motion platform 30;

[0080] The x-direction driving linear motor 50 is used to drive the x-direction moving platform 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com