A damping material and preparation method thereof, and piezoelectric ceramic ultrasonic probe

A technology of piezoelectric ceramics and damping materials, which is applied in the analysis of materials, material analysis using sonic/ultrasonic/infrasonic waves, and instruments, etc., can solve the problem of increasing the high-frequency conductivity of the damping layer, affecting the high-frequency performance of the probe, and curing the damping layer. Time extension and other problems, to achieve the effect of improving resolution, shortening vibration time, and conducive to absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0046] The invention provides a damping material, which comprises 60-120 parts of high molecular polymer, 30-60 parts of sheet-like structure inorganic filler, 5-15 parts of spherical structure inorganic filler, and 0.5 parts of silane additives in proportion by weight. -5 parts, solvent 10-30 parts.

[0047]The high molecular polymer is at least one of polyacrylic resin, polyacrylic resin copolymer, epoxy resin or polyurethane resin.

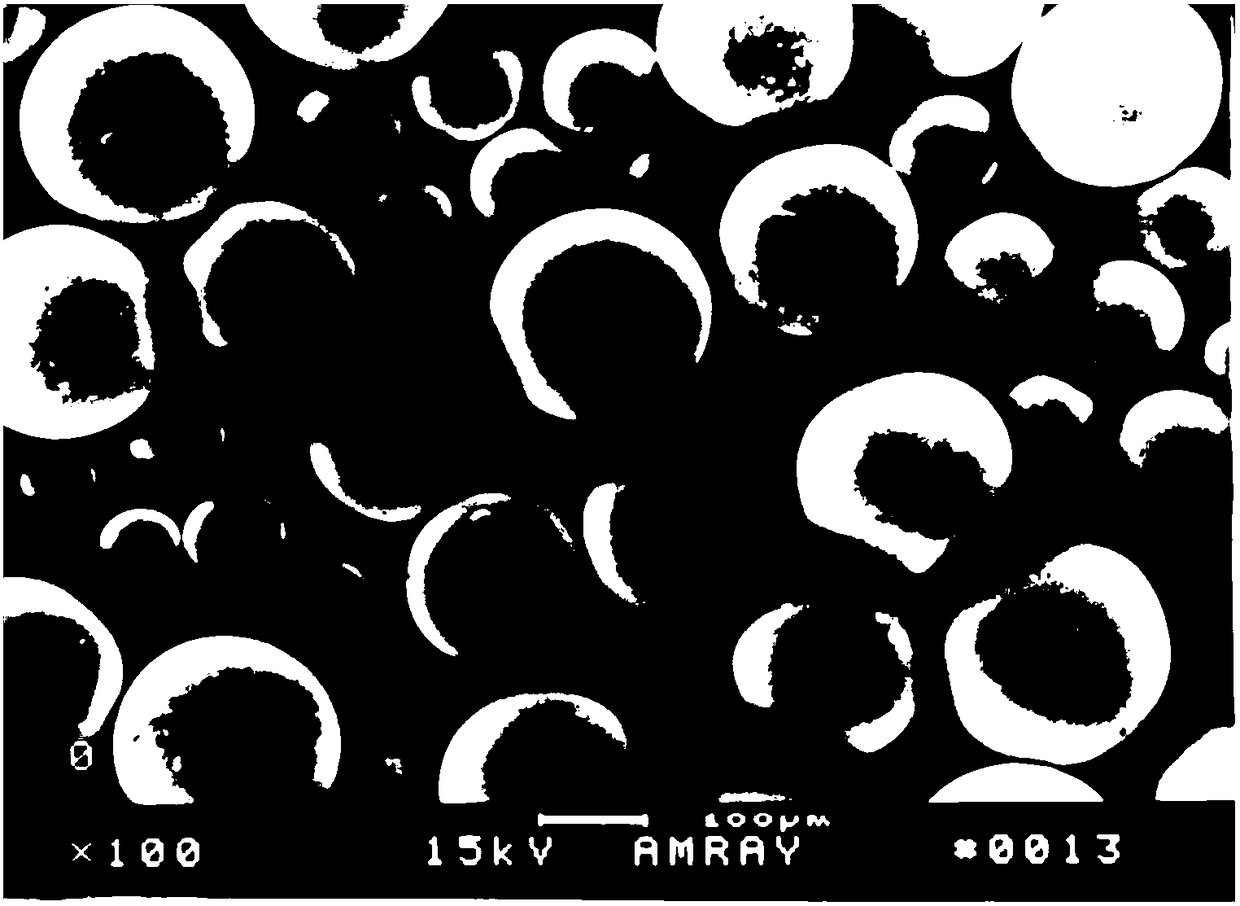

[0048] The sheet-like structure inorganic filler is at least one of mica, volcanic ash or vermiculite, and the particle size of the sheet-like structure inorganic filler is between 0.1-250 μm, such as figure 1 shown.

[0049] The spherical structure inorganic filler is at least one of calcium carbonate, silicon dioxide, silica fume or talc, and the particle size of the spherical structure inorganic filler is between 0.05-10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com