A kind of rapid maintenance material and preparation method thereof

A fast, polymer material technology, applied in the field of rail transit, can solve the problems that cannot be adopted on a large scale, affect the train punctuality rate and train operation map, and cannot be used for a long time, and achieve excellent dynamic load performance, good fluidity, and good Effects of fatigue resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1. Preparation of epoxy-modified polymer materials

[0056] 1.1 Composition and dosage of epoxy modified polymer materials

[0057]

[0058] 1.2 The preparation method of epoxy modified polymer material is as follows:

[0059] Add P1000 (Hebei Yadong, hydroxyl value 110 mg KOH / g, f=2, molecular weight 1000), E54 (Shanghai Yueyi Chemical, epoxy equivalent 180-190g / mol) into the reaction kettle, start stirring and raise the temperature to 80°C, the vacuum pump dehydrates the reactor, and the vacuum degree is kept above 0.08 MPa. After keeping for 2 hours, remove the vacuum and cool down to room temperature. Under stirring conditions, slowly add 10 parts of MDI (Yantai Wanhua), and then raise the temperature To 95°C, react for 2-3 hours, take a sample to test the free isocyanate group, when the content is 0%, stop the reaction and discharge.

[0060] 2. Preparation of Component A

[0061] 2.1 Composition and dosage of component A

[0062]

[0063] 2.2 Preparation...

Embodiment 2

[0073] 1. Preparation of epoxy-modified polymer materials

[0074] 1.1 Composition and dosage of epoxy modified polymer materials

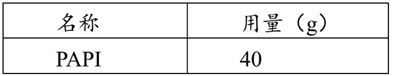

[0075]

[0076] 1.2 The preparation method of epoxy modified polymer material is as follows:

[0077] Add P2000 (Shandong Dongda, hydroxyl value 56 mgKOH / g, f=2, molecular weight 2000), YDF-170 (Japan Dongdu Chemical Co., Ltd., epoxy equivalent 160-180g / mol) into the reaction kettle, start stirring and Raise the temperature to 80°C, vacuum the reactor for dehydration with a vacuum pump, and keep the vacuum degree above 0.08MPa. After keeping for 2 hours, remove the vacuum and cool down to room temperature. Slowly add 12 parts of PAPI under stirring conditions, and then raise the temperature to 95°C , react for 2 to 3 hours, take a sample to test the free isocyanate group, when the content is 0%, stop the reaction and discharge.

[0078] 2. Preparation of Component A

[0079] 2.1 Composition and dosage of component A

[0080]

[0081] 2.2...

Embodiment 3

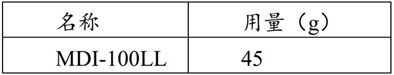

[0091] 1. Preparation of epoxy-modified polymer materials

[0092] 1.1 Composition and dosage of epoxy modified polymer materials

[0093]

[0094] 1.2 The preparation method of epoxy modified polymer material is as follows:

[0095] P1000 (Hebei Yadong, hydroxyl value 110 mg KOH / g, f=2, molecular weight 1000), P2000 (Shandong Dongda, hydroxyl value 56 mgKOH / g, f=2, molecular weight 2000), E54 (Shanghai Yue Yi Chemical, epoxy equivalent 180-190g / mol) into the reaction kettle, start stirring and raise the temperature to 80°C, the vacuum pump dehydrates the reaction kettle, and the vacuum degree is kept above 0.08Mpa. After keeping for 2 hours, remove the vacuum and lower the temperature. To room temperature, under stirring conditions, slowly add 14 parts of PAPI (Yantai Wanhua), after completion, raise the temperature to 95 ° C, react for 2 to 3 hours, take a sample to test the free isocyanate group, when the content is 0%, stop the reaction and discharge .

[0096] 2. Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com