Epoxy structure adhesive for rotor blades and preparation method thereof

A technology of epoxy structural glue and wind rotor blades, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of high brittleness, severe curing heat release of epoxy resin adhesive, and severe curing heat release, etc. To achieve the effect of changing the brittleness, prolonging the curing time and increasing the cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Accurately weigh the following raw materials: 58 g of bisphenol A epoxy resin, 10 g of bisphenol F epoxy resin, 9685 g of hyperbranched urethane acrylate, 12 g of fumed silicon, 5 g of triphenyl phosphorus oxide, 1,4-butane Glycol diglycidyl ether 10g, the above components are added into the double planetary power mixing mixer in turn, vacuumed to -0.1MPa, the rotation speed is 1000 rev / min, the revolution speed is 10 rev / min under the condition, mechanical stirring 1.5 hours to obtain component A, mix evenly to obtain component A of the epoxy resin adhesive, package and set aside for use; curing agents such as diethylenetriamine 3g, isophorone diamine 42g, polyetheramine 37g, bis( 13 g of 4-amino-3-methylcyclohexyl) methane, and 5 g of a thixotropic agent such as fumed silica are mixed evenly to obtain the B component of the epoxy resin adhesive, which is packaged and placed for use.

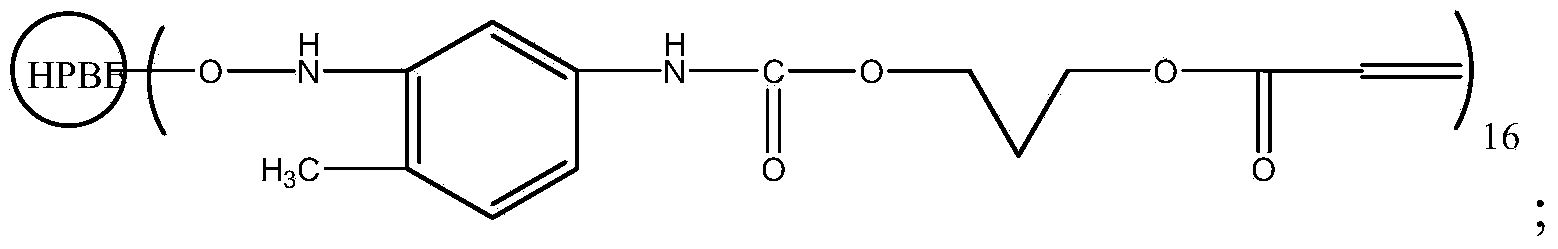

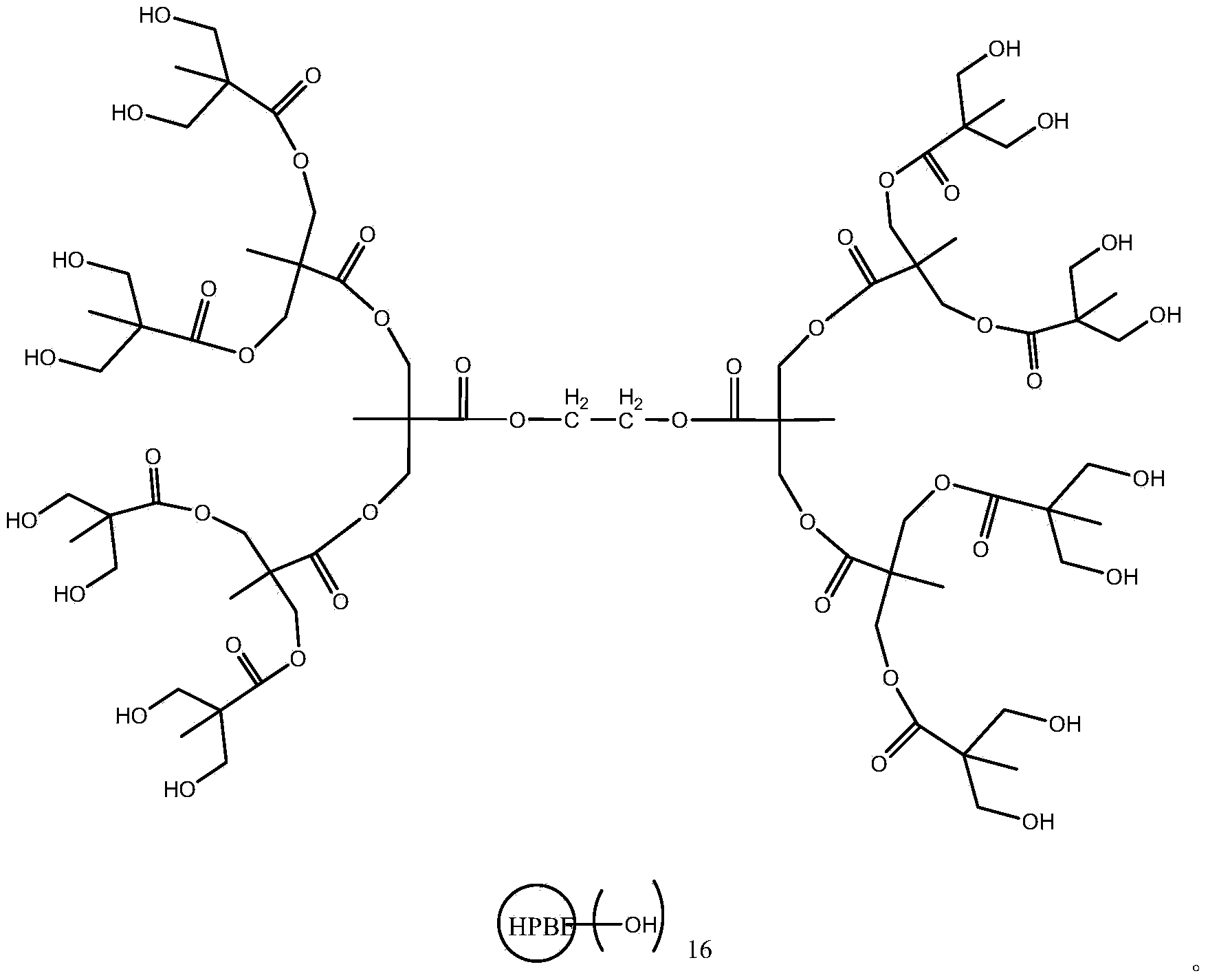

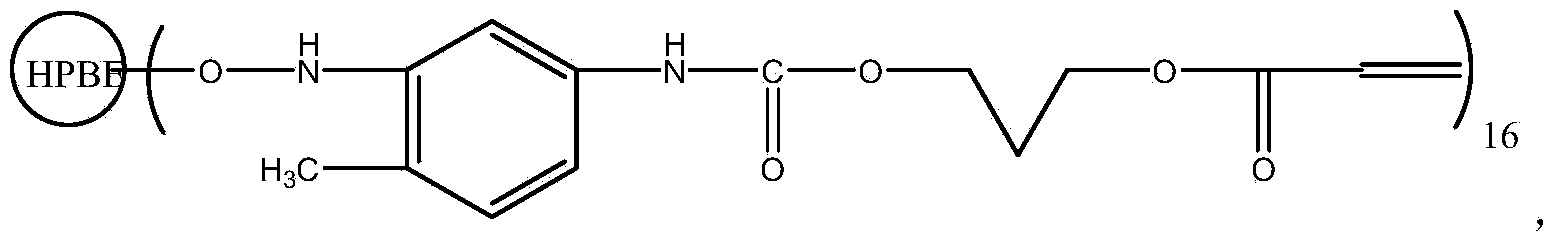

[0030] The hyperbranched urethane acrylate is a dendritic polymer with a highly bran...

Embodiment 2

[0036]Accurately weigh the following raw materials, 50 g of bisphenol A epoxy resin, 10 g of bisphenol F epoxy resin, 10 g of hyperbranched urethane acrylate CN9688, 18 g of fumed silicon, 2 g of triphenyl phosphorus oxide, 1,4-butanedi 10 g of alcohol diglycidyl ether, the above components are added into the double planetary power mixing mixer in turn, vacuumed to -0.1MPa, under the condition that the rotation speed is 1000 rev / min and the revolution speed is 8 rev / min, mechanically stir 2 hours to obtain component A, mix evenly to obtain component A of the epoxy resin adhesive, package and place for use; curing agents such as N-aminoethylpiperazine 3g, isophorone diamine 39g, polyetheramine 37g , 13g of bis(4-amino-3-methylcyclohexyl) methane, and 8g of thixotropic agent such as fumed silica are mixed evenly to obtain the B component of the epoxy resin adhesive, which is packaged and placed for use.

[0037] When in use, the prepared A component and B component are mixed uni...

Embodiment 3

[0039] Accurately weigh the following raw materials: 50g of bisphenol A epoxy resin, 10g of bisphenol F epoxy resin, 62g of hyperbranched urethane acrylate CN90062g, 23g of fumed silicon, 10.5g of resorcinol, 1,6-hexanediol 9.5g of alcohol diglycidyl ether, the above components were added to the double planetary power mixing mixer in turn, vacuumed to -0.1MPa, under the condition that the rotation speed was 1000 rev / min and the revolution speed was 10 rev / min, the mechanical Stir for 2 hours to obtain component A, mix evenly to obtain component A of the epoxy resin adhesive, package and place for use; curing agents such as isophorone diamine 42g, polyetheramine 32g, bis(4-aminocyclohexyl ) 7 g of methane, 9 g of diaminodiphenylmethane, and 10 g of a thixotropic agent such as fumed silicon are mixed evenly to obtain the B component of the epoxy resin adhesive, which is packaged and placed for use.

[0040] When in use, the prepared A component and B component are mixed uniforml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com