Repair composition for concrete structural components of slab ballastless track, its preparation method and use

A slab ballastless track and concrete structure technology, applied in the field of building materials, can solve the problems of low strength, low physical performance strength, and large number of maintenance personnel, and achieve good fatigue resistance and impact resistance, excellent dynamic load performance, Environmentally adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Composition and dosage of polyurethane prepolymer PU-1

[0050] name Dosage (parts by mass) 330N 4 Polyether 2000 8 1,4-Butanediol 2 MDI 10

[0051] Polyurethane prepolymer preparation method is as follows:

[0052] Add 4 parts of 330N (Gaoqiao Petrochemical, hydroxyl value 35mg KOH), 8 parts of polyether 2000 (Gaoqiao Petrochemical GE220, hydroxyl value 56mg KOH), 2 parts of 1,4-butanediol into the reaction kettle, start stirring and raise the temperature To 120°C, the vacuum pump dehydrates the reactor, and the vacuum degree is kept above 0.08MPa. After keeping for 2 hours, remove the vacuum and cool down to room temperature. Under stirring conditions, slowly add 10 parts of MDI, and then heat up to 70°C. React for 2-3 hours, take a sample every 1 hour to test the free isocyanate group, when the content of isocyanate group is 5%, stop the reaction and discharge the material and keep it sealed for later use.

[0053] A component...

Embodiment 2

[0072] Components and dosage of polyurethane prepolymer PU-2

[0073] name Dosage (parts by mass) PTMG2000 10 1,4-Butanediol 2 MDI 11

[0074] The preparation method of polyurethane prepolymer PU-2 is as in Example 1.

[0075] A component composition and dosage

[0076]

[0077] A component was prepared as in Example 1.

[0078] Composition and dosage of component B

[0079] name Dosage (parts) T31 15 701 20 A200 5

[0080] The B component was prepared as in Example 1.

[0081] C component composition and dosage

[0082] name Dosage (parts by mass) 8~10 mesh 30 10~20 mesh 35 20~40 mesh 35

[0083] The physical properties of A, B mixture (A:B=2.5:1 mass parts) are as follows:

[0084] Test items Performance gel time 28min 2 hours strength test Reach over 85% of final strength Bonding strength to concrete 4.9 MPa elongation at break ...

Embodiment 3

[0088] Composition and dosage of polyurethane prepolymer PU-3

[0089]

[0090]

[0091] The preparation method of polyurethane prepolymer PU-3 is as in Example 1.

[0092] A component composition and dosage

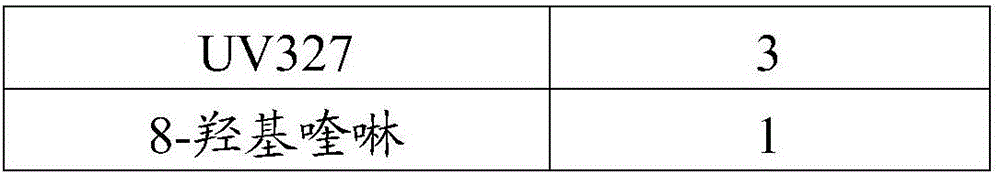

[0093]

[0094] A component was prepared as in Example 1.

[0095] Composition and dosage of component B

[0096] name Dosage (parts by mass) 701 30 Nonylphenol 5 A200 5

[0097] The B component was prepared as in Example 1.

[0098] C component composition and dosage

[0099] name Dosage (parts by mass) 8~10 mesh 30 10~20 mesh 40 20~40 mesh 30

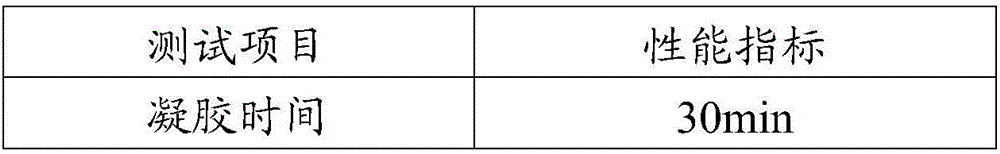

[0100] The physical properties of A, B mixture (A:B=2.5:1 mass parts) are as follows:

[0101]

[0102]

[0103] The relationship between the amount of component C and the strength of the material is as follows:

[0104]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com