Bi-component addition type heat-conducting silica gel for heat dissipation of LED lighting chip

A technology of heat-conducting silica gel and addition type, which is applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc. Problems such as high viscosity of heat-conducting silicone products, to achieve the effect of good production operation, good curing effect and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

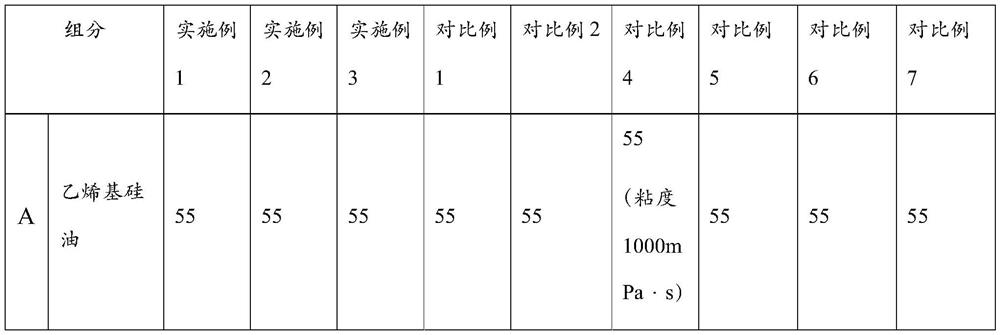

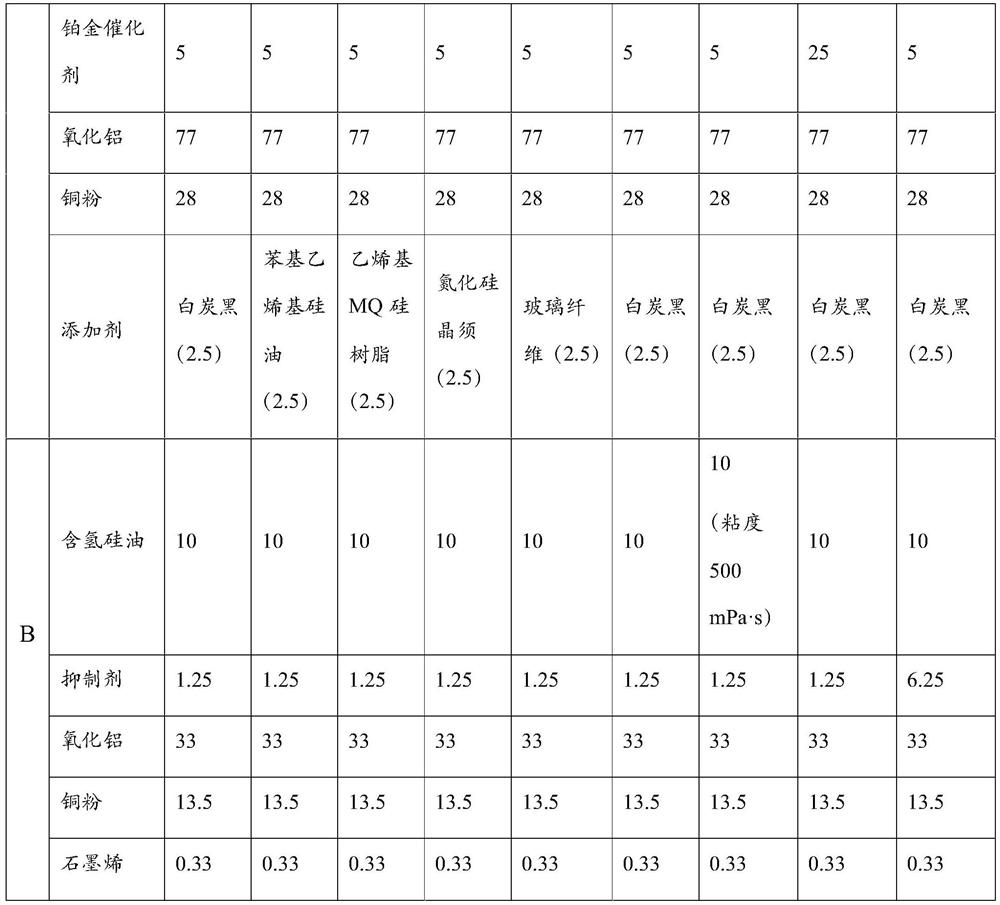

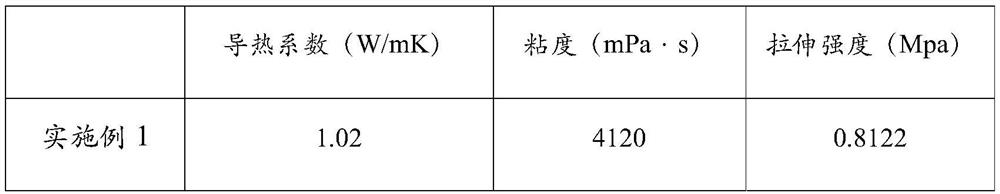

[0061] This thermally conductive silicone rubber is a two-component addition type liquid silicone rubber, in which

[0062] A component: vinyl silicone oil, platinum catalyst, alumina, copper powder, reinforcing and toughening additives

[0063] B component: hydrogen silicone oil, inhibitor, alumina, copper powder, graphene

[0064] Among them, the vinyl silicone oil is double-ended vinyl silicone oil produced by Jinan Guobang Chemical Co., Ltd., with a viscosity of 400mPa·s and a vinyl content of 0.86%; the hydrogen-containing silicone oil is selected from RH-H3 produced by Ningbo Runhe Material Co., Ltd. The hydrogen content is 0.28%, and the viscosity is 100mPa s; the platinum catalyst is the platinum catalyst produced by Huayuanhong Chemical Co., Ltd., and the platinum concentration is 5000ppm; the inhibitor is ethynyl cyclohexanol (PC00685) produced by Guangdong Wengjiang Chemical Reagent Co., Ltd. , and use dimethyl silicone oil to prepare it into a solution with a mass...

Embodiment 2

[0073] Compared with Example 1, the difference is that the white carbon black is replaced by an equal amount of phenyl vinyl silicone oil, the vinyl content is 1.78%, and the viscosity is 1670 mPa·s.

Embodiment 3

[0075] Compared with Example 1, the difference is that the white carbon black is replaced by vinyl MQ silicone resin, the vinyl content is 1.38%, and the viscosity is 8662mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com