Automatic feeding device and control method for buzzer dispensing

A technology of automatic feeding and buzzer, which is used in conveyor control devices, devices for coating liquid on surfaces, vibrating conveyors, etc., which can solve the problem of unreasonable structure, affecting the dispensing effect, and inaccurate docking of positioning devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

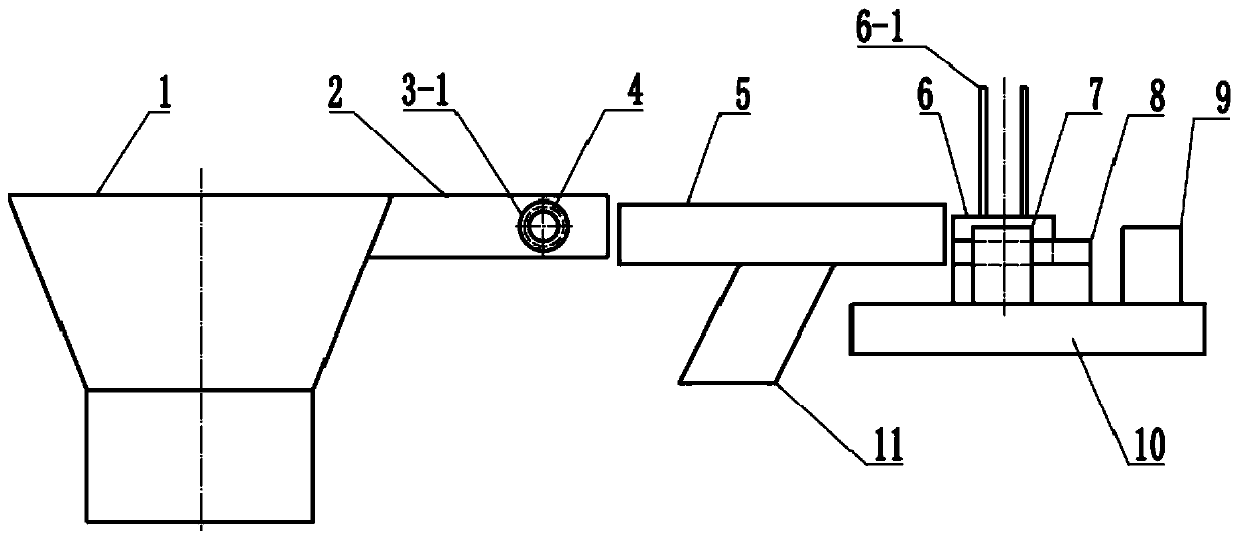

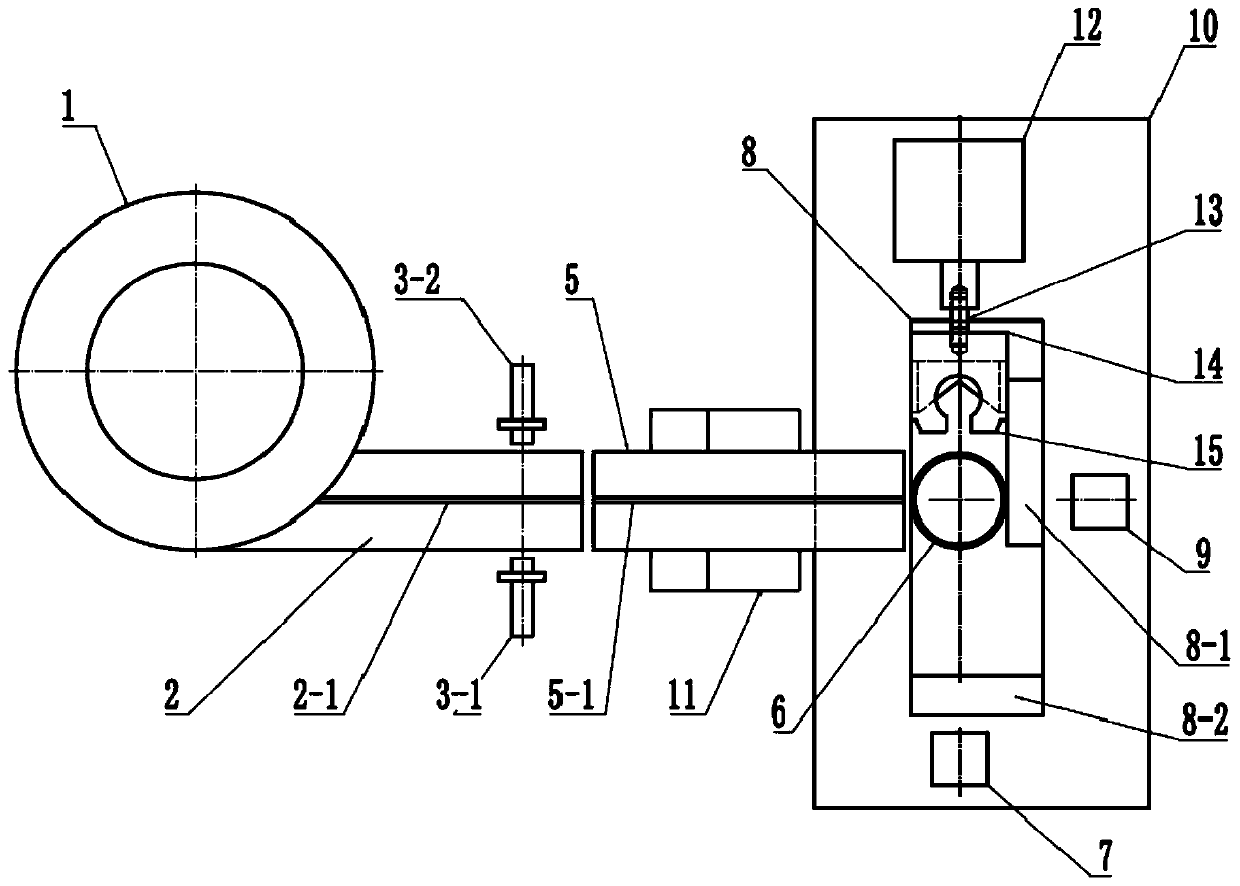

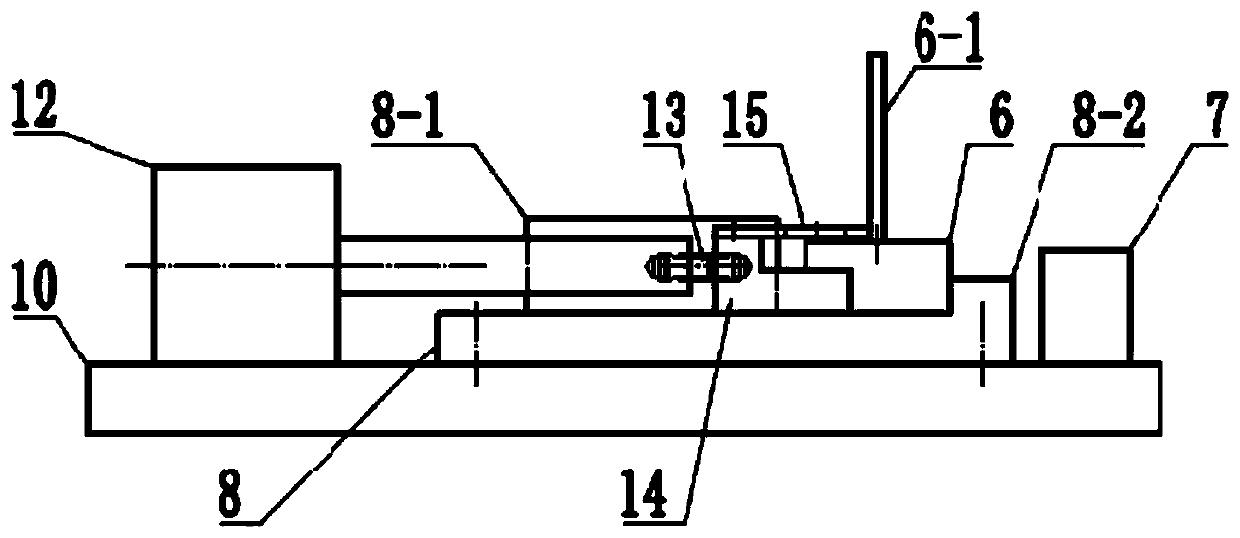

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] A buzzer dispensing automatic feeding device of the present invention such as figure 1 , figure 2 , image 3 As shown, the first feeding guide rail 2 is welded to the outlet of the spiral track of the vibrating plate 1, and can vibrate together with the vibrating plate 1. The first feeding guide rail 2 outlet is equipped with an opposite-beam optical fiber sensor 3, wherein the transmitting end 3-1 and the receiving end 3-2 are respectively installed on both sides of the first feeding guide rail 2 outlet, and the first feeding guide rail 2 exits. The feed port is processed with a light hole 4 at the axis passing position of the transmitting end 3-1 and the receiving end 3-2, and the light emitted by the emitting end 3-1 can be irradiated to the receiving end 3-2 through the light hole 4.

[0031] The second feeding guide rail 5 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com