Vibration wave motor and lens barrel

A technology of vibration wave and vibrator, which is applied in the direction of generators/motors, circuits, electrical components, etc., can solve the problem of not fully considering the unitization of driving sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Embodiments of the present invention will be described below with reference to the drawings.

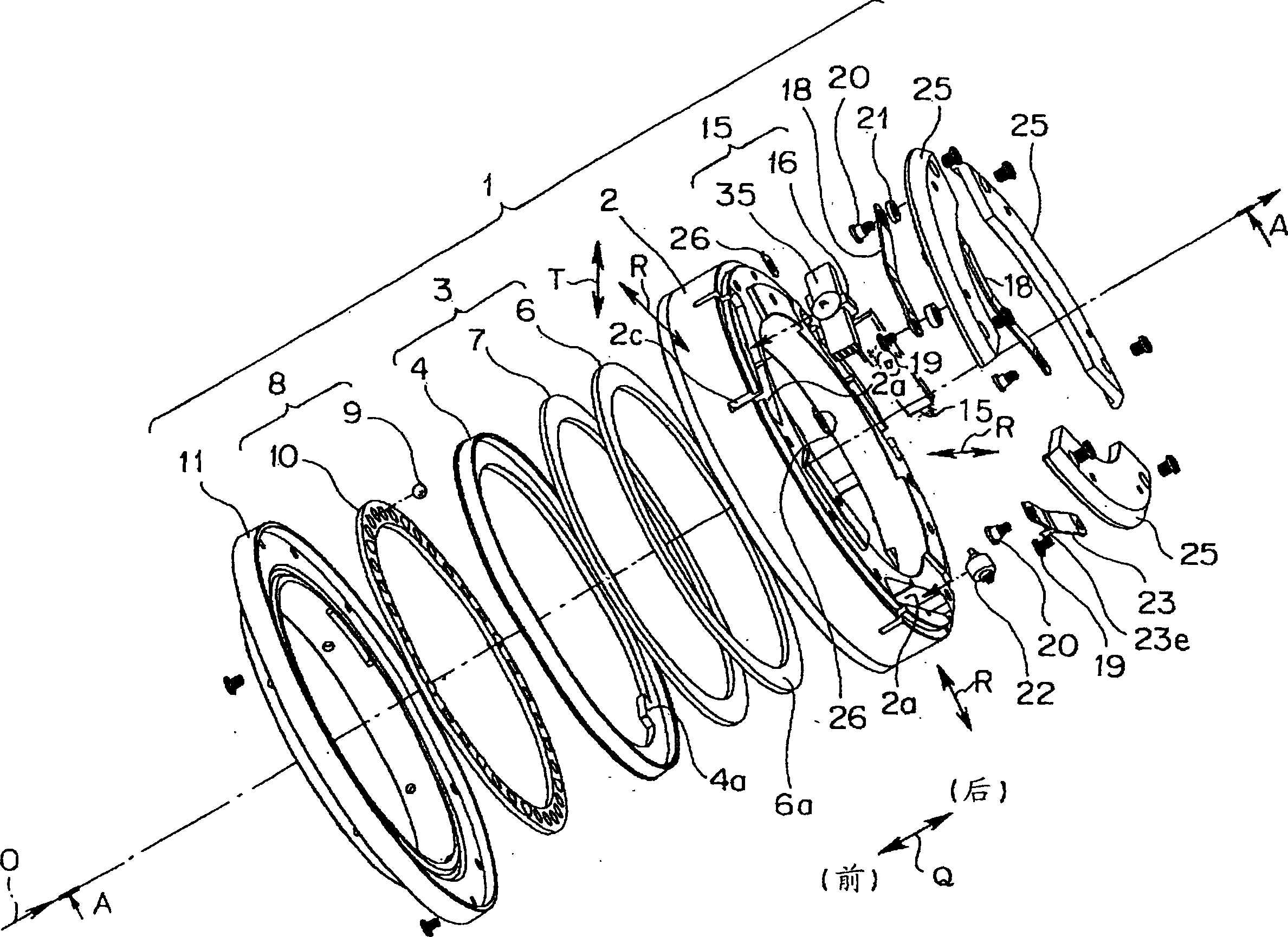

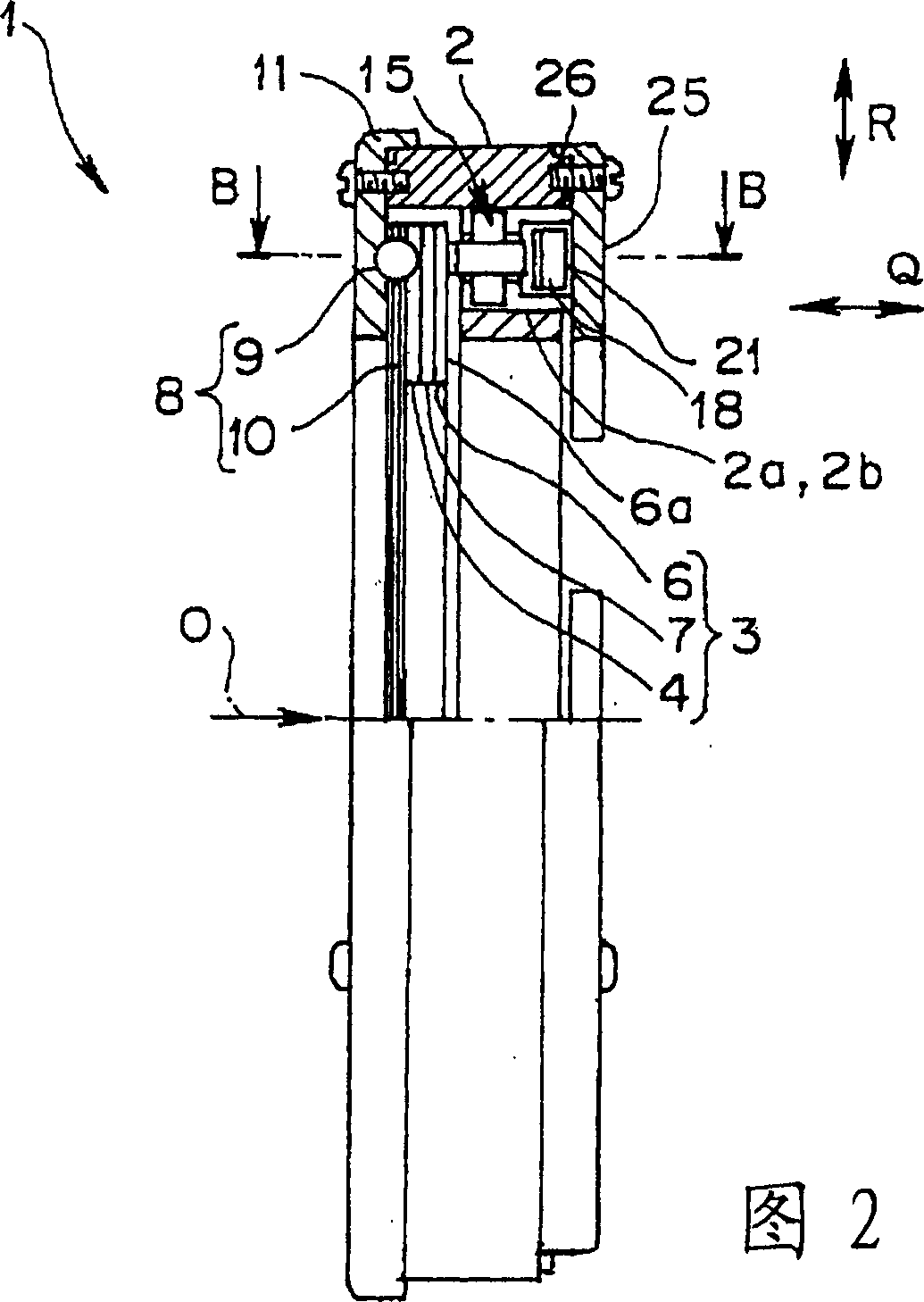

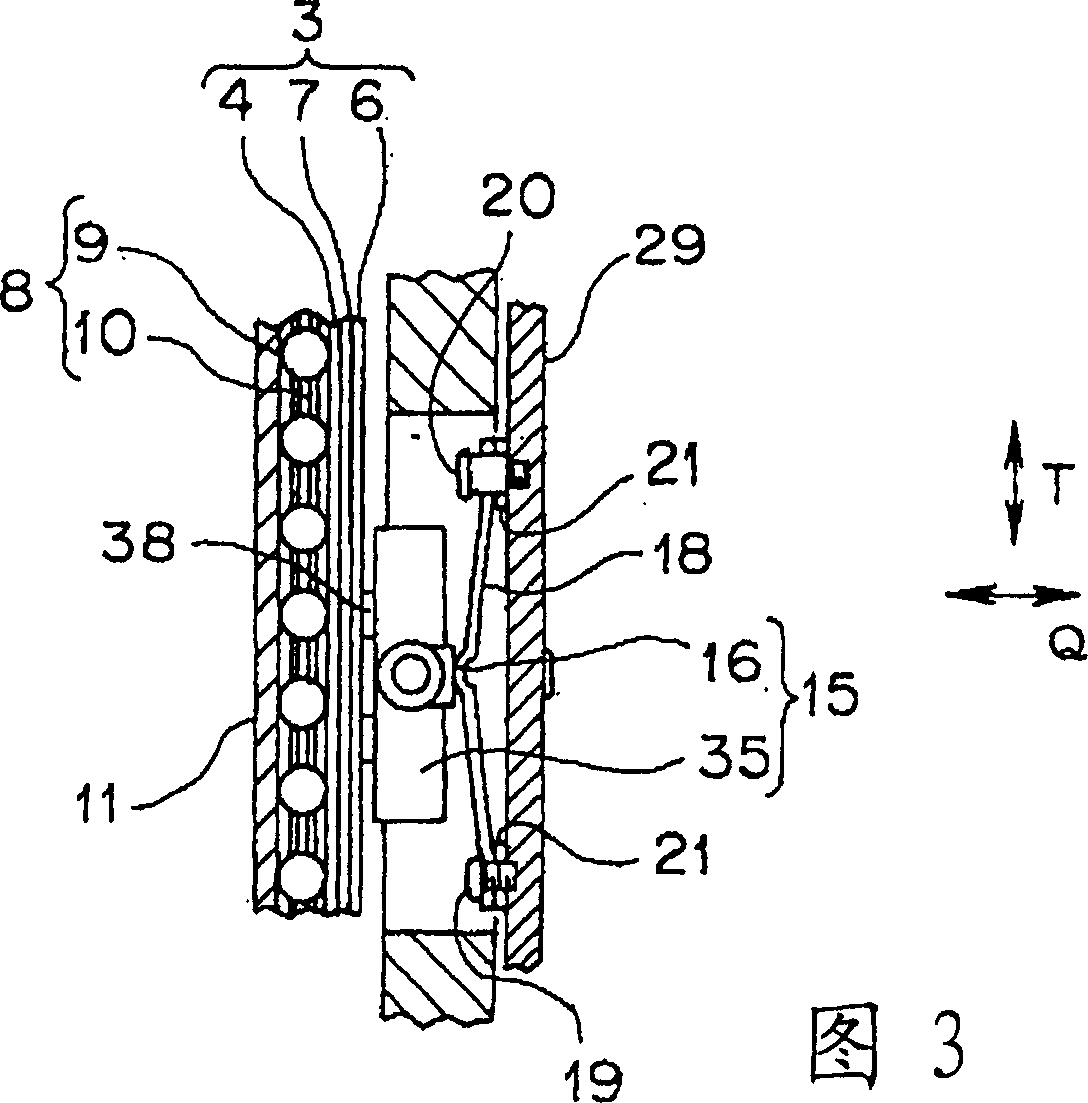

[0080] figure 1 It is an exploded perspective view of the vibration wave motor according to one embodiment of the present invention.

[0081] In the following description, when the vibration wave motor is used on the lens barrel described later, the rotation axis O of the vibration wave motor coincides with the optical axis O of the photographing lens (according to the structure of the above-mentioned lens barrel, approximately coincides). Also, let the direction parallel to the rotation axis O be the Q direction. In the Q direction, the lens side of the lens barrel is defined as the front, and the lens holder side is defined as the rear. In addition, let the radial direction with respect to the rotation axis O be the R direction, and let the tangential direction of the circumference around the rotation axis O be the T direction.

[0082] The vibration wave motor 1 of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com