Ultrasonic wave motor transient characteristic testing device and control system thereof

A technology of ultrasonic motor and transient characteristics, applied in the direction of motor generator testing, etc., can solve the problems of large output power of hysteresis dynamometer, huge test device, difficulty in obtaining transient characteristic test performance of motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

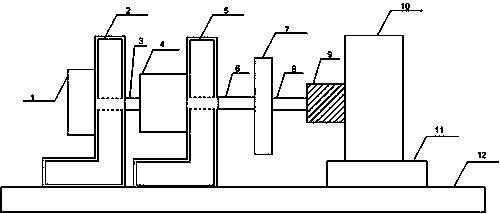

[0082] Ultrasonic motor transient characteristic testing device of the present invention, such as figure 1 As shown, it includes a base 12 and an ultrasonic motor 4 arranged on the base 12, the output shaft 3 of the ultrasonic motor 4 is connected to the photoelectric encoder 1, and the output shaft 6 on the other side is connected to the flywheel inertial load 7 , the output shaft 8 of the flywheel inertial load 7 is connected to the torque sensor 10 through the elastic coupling 9, and the signal output end of the photoelectric encoder 1 and the signal output end of the torque sensor 10 are respectively connected to the control system.

[0083] The ultrasonic motor 4 , photoelectric encoder 1 and torque sensor 10 are respectively fixed on the base 12 via the ultrasonic motor fixing bracket 5 , the photoelectric encoder fixing bracket 2 and the torque sensor fixing bracket 11 .

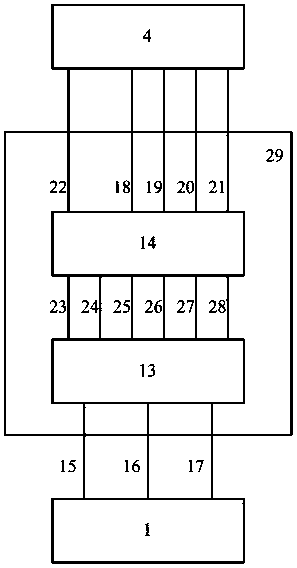

[0084] Such as figure 2 As shown, the above-mentioned control system includes an ultrasonic moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com