Electric main shaft and machine tool

An electric spindle and shaft core technology, which is used in grinding machine parts, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of elongation fluctuation, inconsistency in elongation, and difference in machining accuracy at both ends of the spindle. , to achieve the effect of eliminating elongation, maintaining stable processing accuracy and stable processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

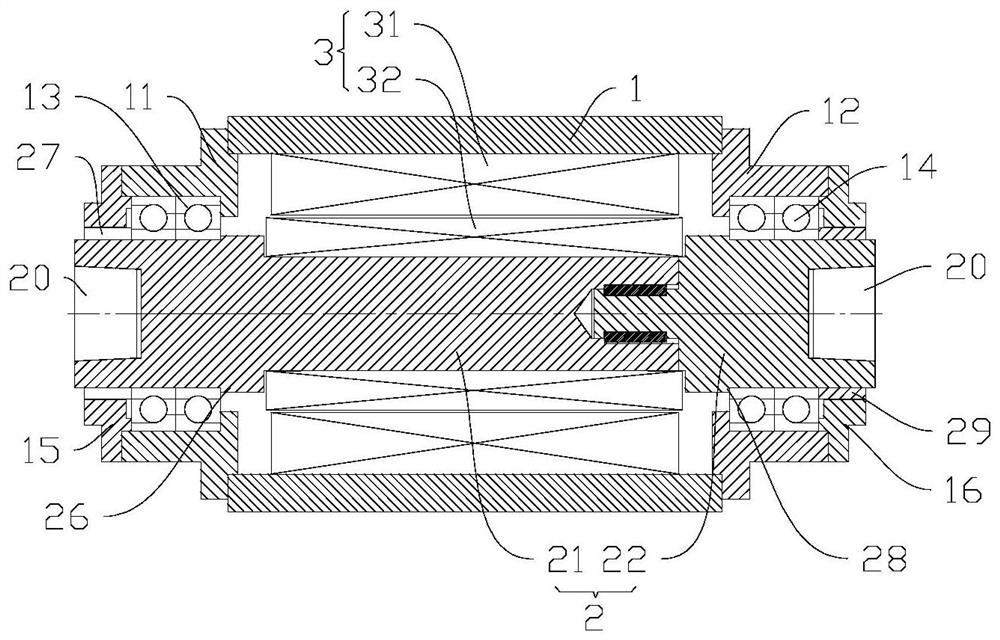

[0026] This part will describe the specific embodiment of the present invention in detail, and the preferred embodiment of the present invention is shown in the accompanying drawings. Each technical feature and overall technical solution of the invention, but it should not be understood as a limitation on the protection scope of the present invention.

[0027] In the present invention, "several" means one or more, "multiple" means more than two, "greater than", "less than", "exceeding", etc. are understood as excluding the original number; "above", "below", "within" " and so on are understood as including the original number. In the description of the present invention, if "first" and "second" are used only for the purpose of distinguishing technical features, it should not be understood as indicating or implying relative importance or implicitly indicating the number of indicated technical features or Implicitly indicates the sequence of the indicated technical features.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com