Three-way loading and bending elbow pipe device and method

A technology of pipe bending device and axial loading, applied in the field of three-way loading bending pipe bending device, can solve the problems of reducing wall thickness, stretching the center of the elbow, exceeding the wall thickness, etc. Long and eliminate the effect of thinning and ultra-tolerance of the wall thickness of the elbow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

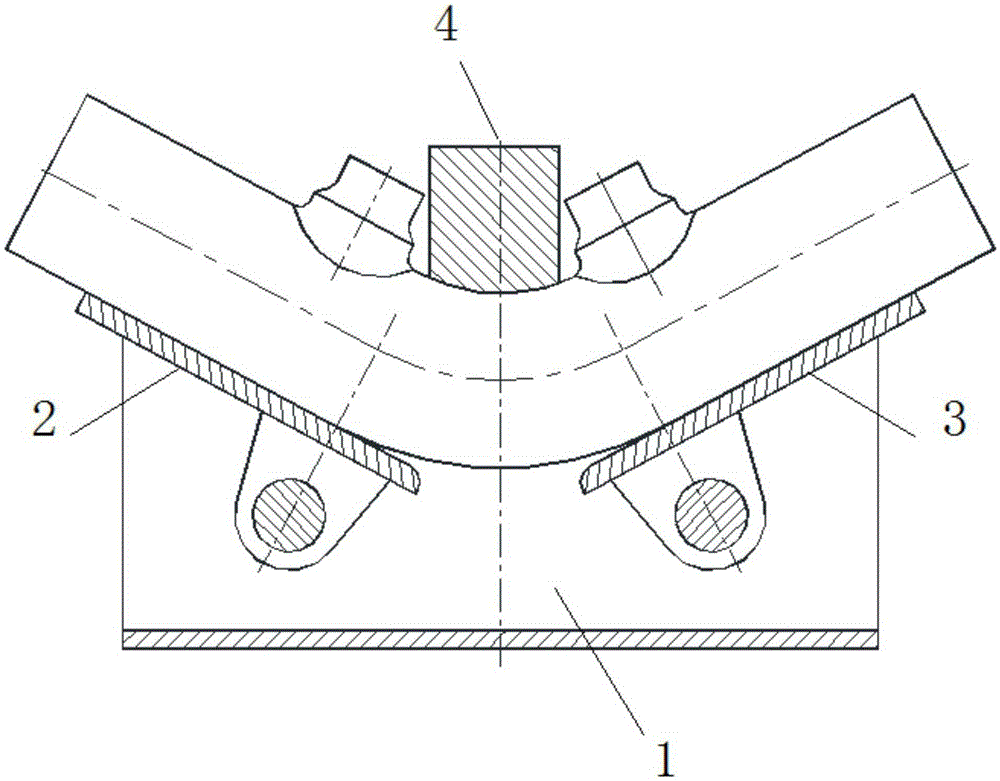

[0043] Such as Figure 4 As shown, the three-way loading bending device includes:

[0044] pedestal 1;

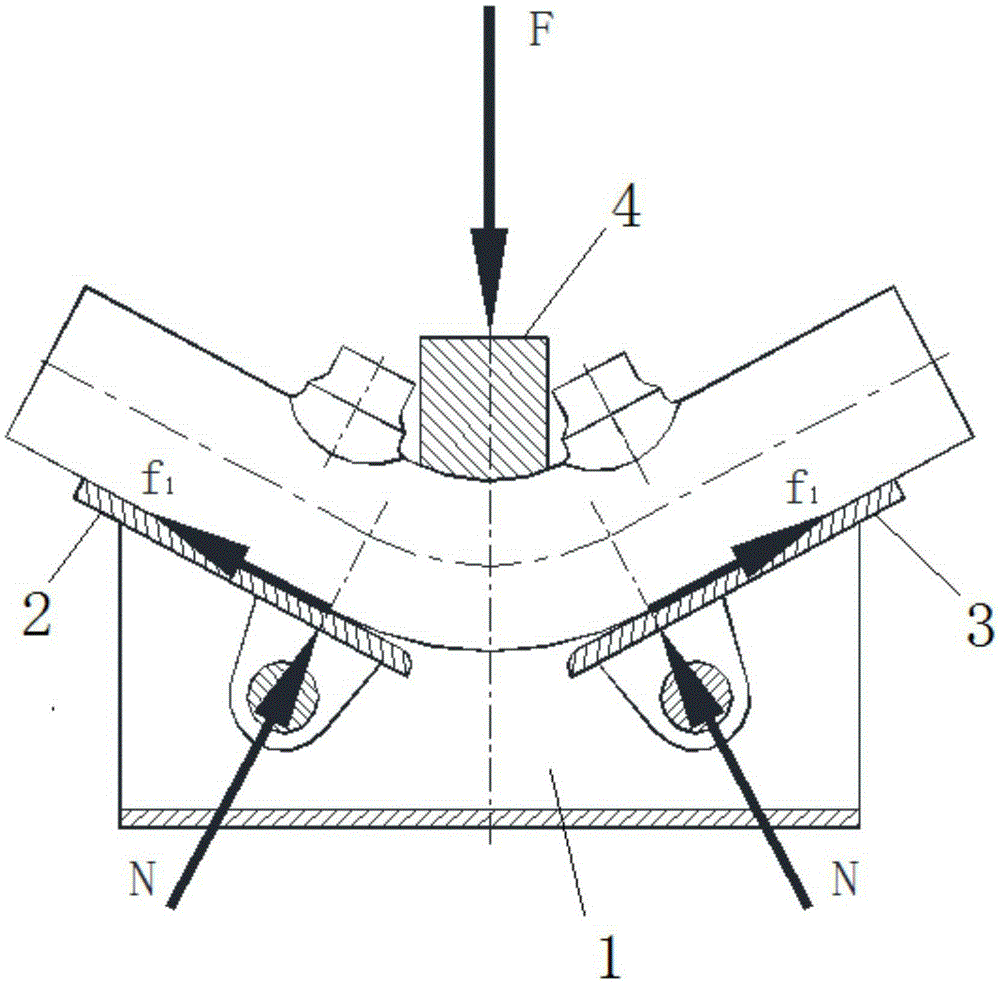

[0045] The left lower mold 2 and the right lower mold 3; the left lower mold 2 and the right lower mold 3 are arranged on the base frame 1, and are arranged on the same horizontal plane, and are used to support the pipe 01 to be bent; the left lower mold 2 and the Described right lower die 3 all can be rotated; After described left lower die and described right lower die rotate, be V-shaped setting (such as Figure 5 shown);

[0046] Upper mold 4; Said upper mold 4 is arranged on said pedestal 1, can rise or fall; Pipe 01 exerts downward pressure F to make the pipe to be bent bend (such as Figure 5 shown);

[0047] Axial loading device; the axial loading device is arranged on the base frame, and loads the pipe to be bent along the axial direction of the pipe to be bent.

[0048] Preferably, the axial loading device includes a loading pad 51; the loading pad 51 is arr...

Embodiment 2

[0068] Such as Figure 6 As shown, different from Embodiment 1, the screw nut 53 of this embodiment is located at the end of the screw rod 52 and abuts against the loading pad 51 . The screw nut 53 rotates to push the loading block 51 to apply pressure to the pipe to be bent along the axial direction of the pipe to be bent.

[0069] Except for the above-mentioned structure, the other structures of the three-way loading bending pipe bending device of this embodiment are the same as those of the device in Embodiment 1.

Embodiment 3

[0071] Such as Figure 7 As shown, different from Embodiment 1, the transmission device of this embodiment also includes a hydraulic device 54, which is connected to the loading pad 51; after the hydraulic device 54 is stretched, it drives the loading pad 51 applies pressure to the pipe to be bent 01 along the axial direction of the pipe to be bent.

[0072] Except for the above-mentioned structure, the other structures of the three-way loading bending pipe bending device of this embodiment are the same as those of the device in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com