Three-dimensional similar model test stand and test method thereof

A technology similar to models and test benches, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve problems such as difficult to achieve three-way loading, hidden dangers, and difficult disassembly of surrounding baffles, etc. Achieve the effect of saving manpower and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

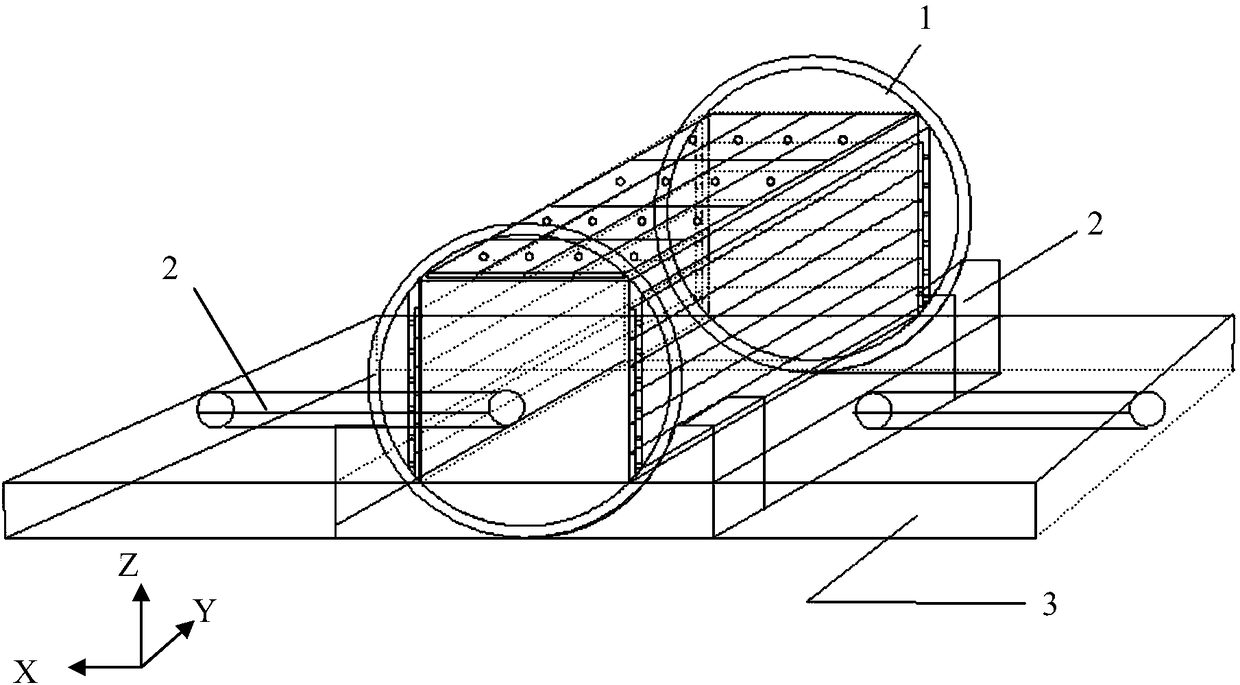

[0090] see Figure 1-20 , Figure 1-20 It is a structural schematic diagram of Embodiment 1 of the present invention. Among them, the left and right sides refer to figure 1 In the X direction, the front and back are located figure 1 In the Y direction, the top and bottom surfaces are located at figure 1 in the Z direction.

[0091] Such as Figure 1-4 As shown, the three-dimensional similar model test bench includes rolling multi-directional loading bench 1 and limit roller 2,

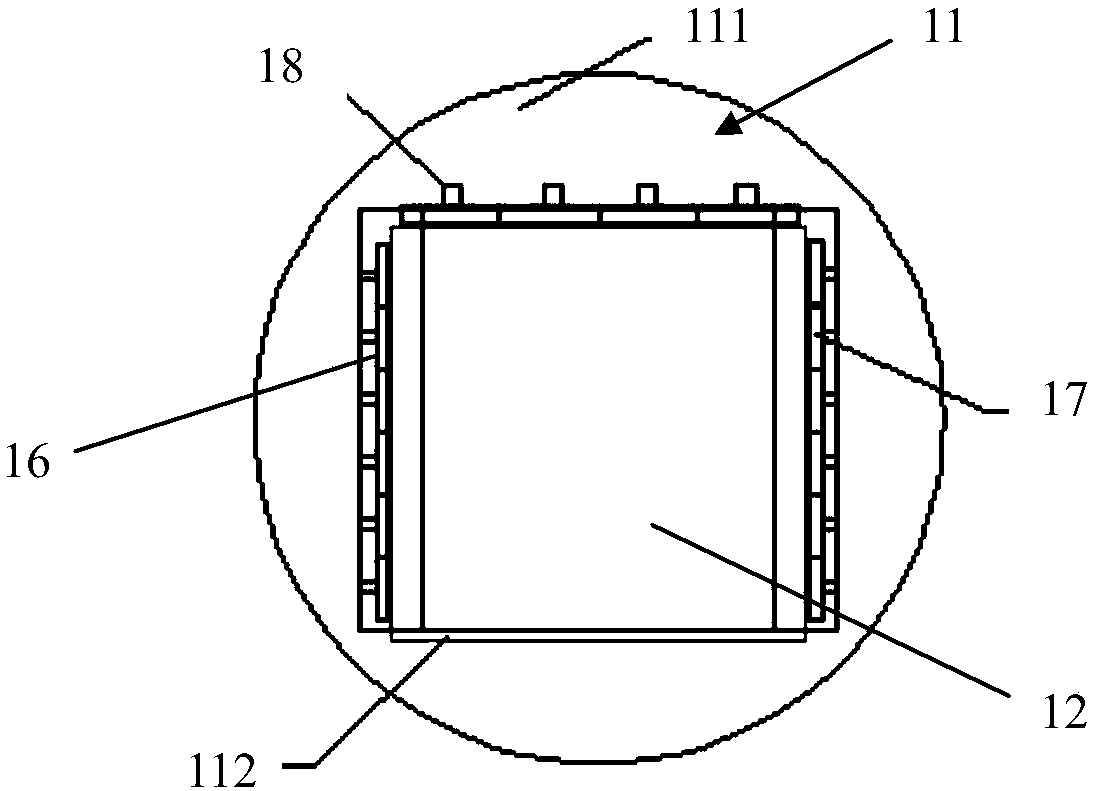

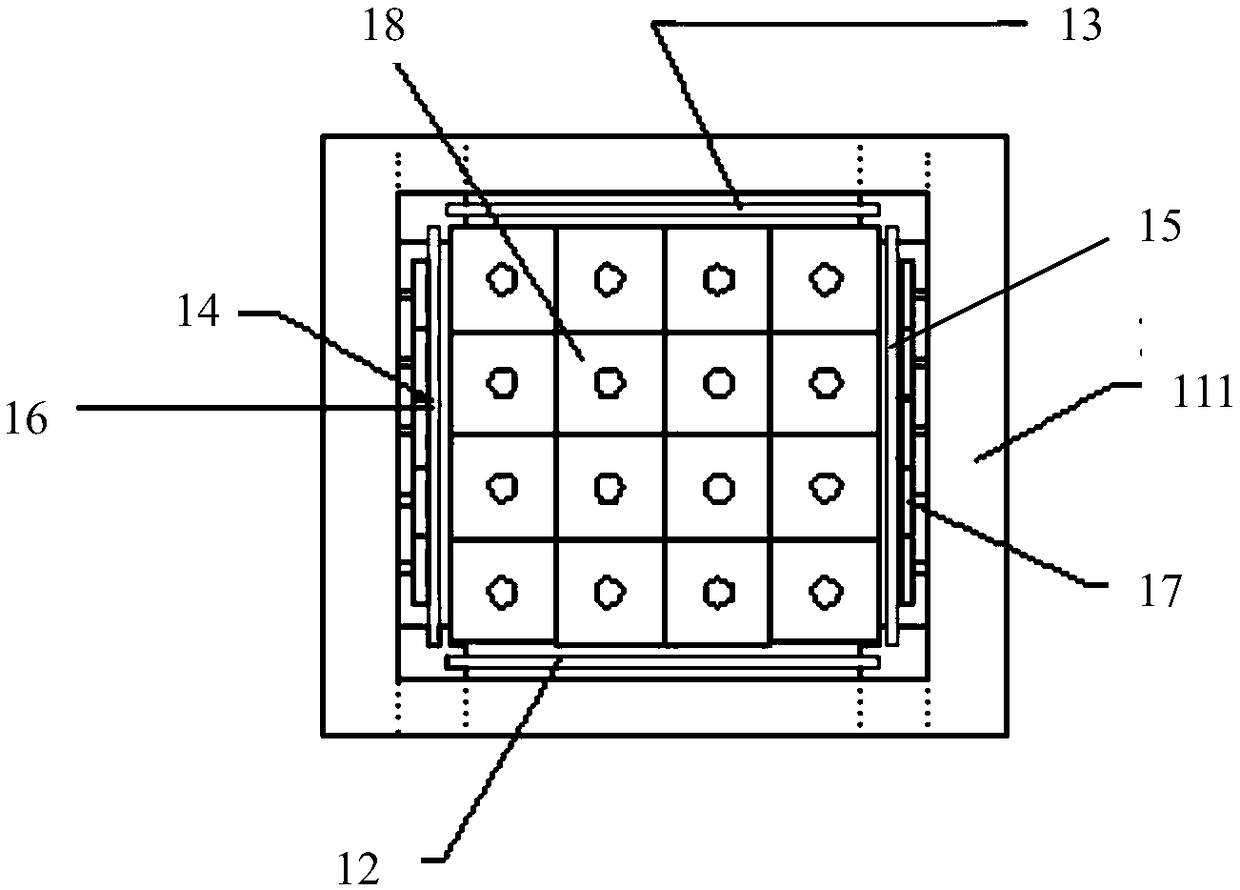

[0092] The rolling multi-directional loading bench 1 includes a barrel frame 11, a front baffle 12, a back baffle 13, a left side baffle 14, a right side baffle 15, a left side loading unit 16, a right side loading unit 17 and a top loading unit. Unit 18;

[0093] The barrel frame 11 includes a hollow cylindrical shell 111, the top surface, front and back of the shell 111 are hollowed out, the barrel frame 11 also includes a bottom plate 112, the bottom plate 112 is installed on the bottom of th...

Embodiment Embodiment 1

[0120] By implementing Embodiment 1, it has the following advantages:

[0121] 1. Through the sealing of the front baffle, the left baffle, the right baffle and the back baffle and the periphery, the sealing performance of the three-dimensional similar model test bench is improved, and it can be applied to the similar model test of solid-liquid coupling.

[0122] 2. The three-way loading of the model is realized through the left loading unit, right loading unit and top loading unit.

[0123] 3. Push the rolling multi-directional loading platform to rotate and maintain it through the limit roller, which can conveniently simulate inclined coal and rock formations at will, and achieve the purpose of safety and reliability during the laying process.

[0124] 4. The left baffle, the right baffle and the back baffle are stacked layer by layer through multiple bars, which are easy to disassemble.

[0125] 5. By arranging the lateral loading system inside the left and right sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com