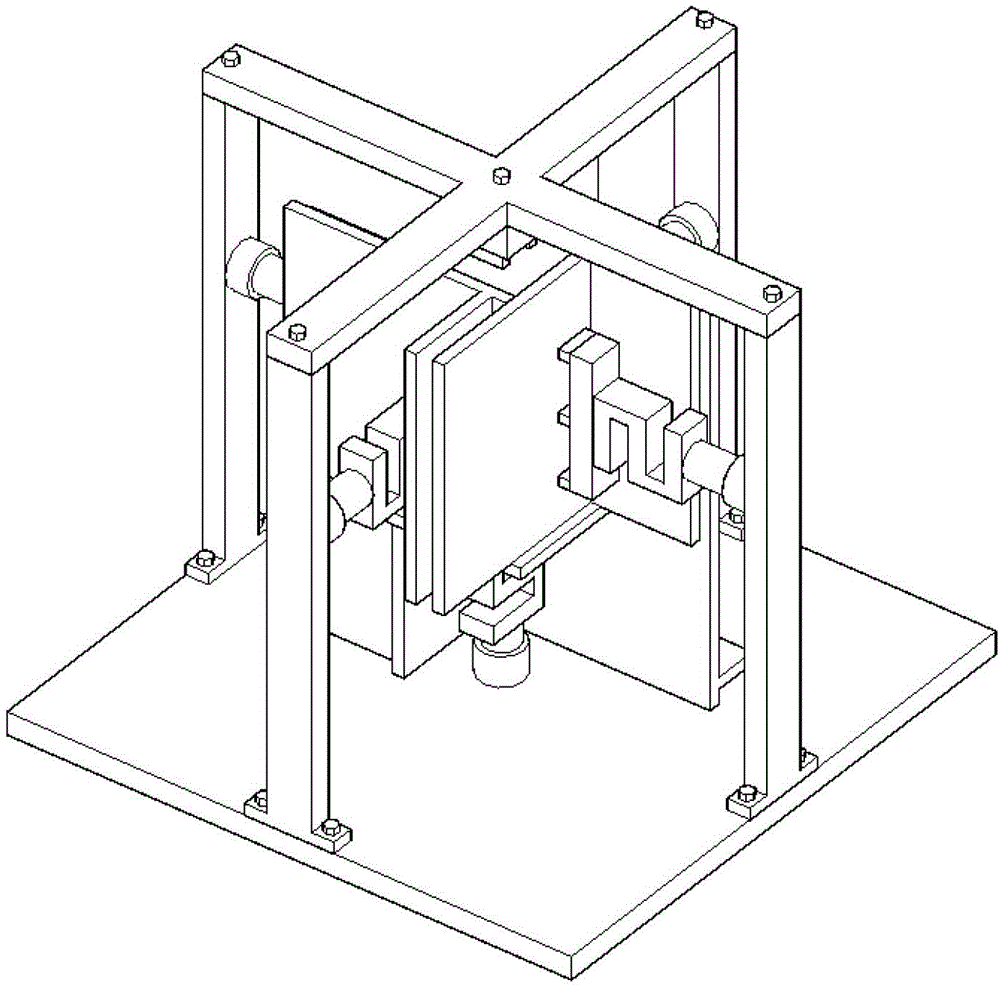

Device and method for measuring actual triaxial creep of geotechnical engineering test specimen

A geotechnical engineering, true triaxial technology is applied in the field of devices for measuring true triaxial creep of geotechnical engineering test blocks, which can solve the problem of not accurately reflecting the real stress and creep behavior of rock and soil, and the loss of triaxial creep. Accuracy, lack of geotechnical research and other problems, to achieve the effect of long test period, slow deformation, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

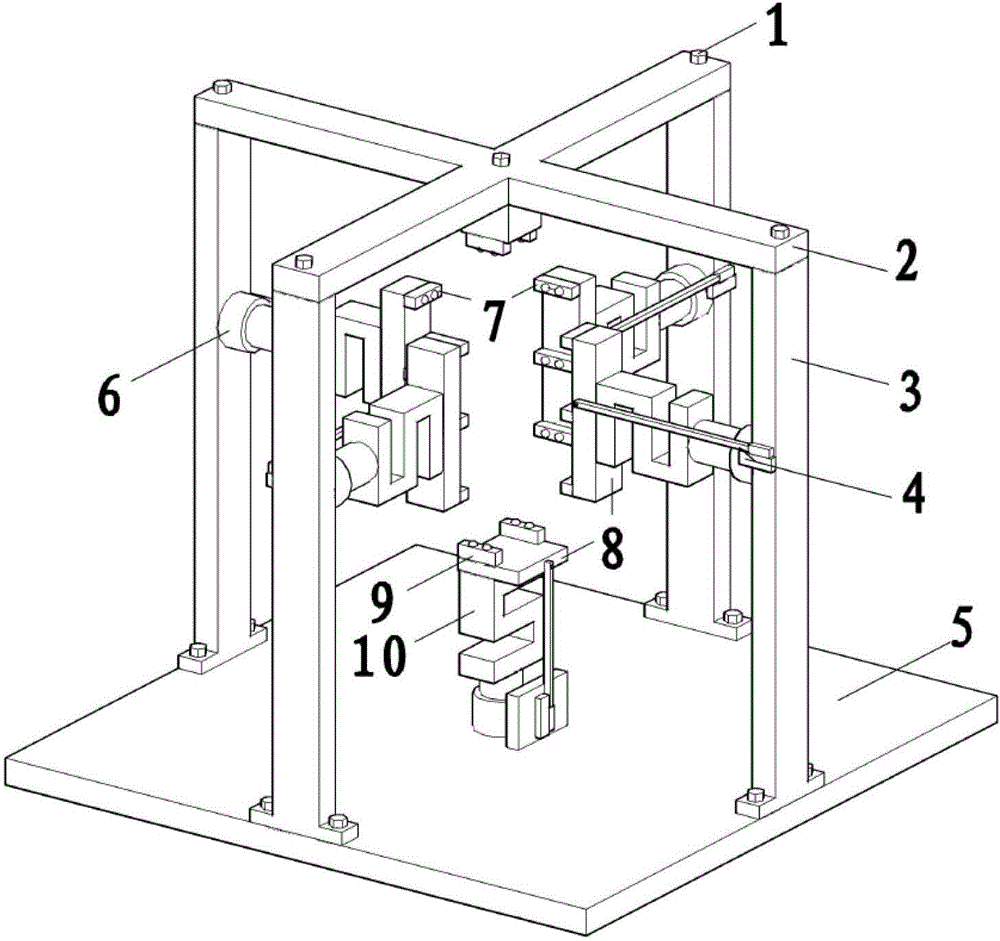

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the following description is only for explaining the present invention and not limiting its content.

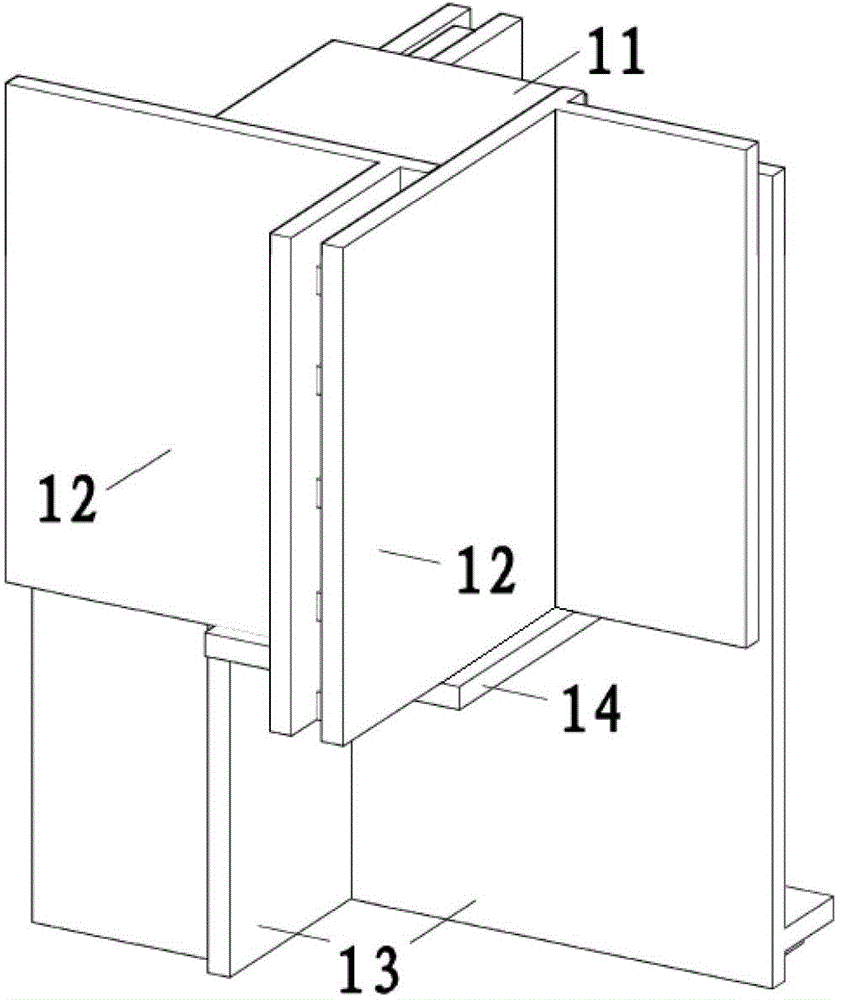

[0046]The present invention includes a support structure, and the inside of the support structure slides and overlaps four confining pressure plates and upper and lower pressure plates to form a closed cavity for wrapping the test block; the confining pressure plates include two long confining pressure plates 13 and two short confining pressure plates 14. The upper and lower pressure plates are rectangular top steel plates 11 and bottom steel plates 14. Two "L" shaped long enclosure pressure plates 13 bent outwards are set up on the adjacent two sides of the bottom steel plate 14, and the remaining two Two "L" shaped short enclosures 12 bent outwards are set up on the side, and the bottom of the short enclosures 12 is placed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com