Driving method for driven object, and driving device and printer of using same

A technology of a driven body and a driving method, applied in printing devices, kerning mechanisms, motor-generator control, etc., can solve problems such as difficulty in repair or adjustment, non-uniformity, lack of mass productivity, etc., to eliminate elongation or spacing changes, eliminating stop lag, maintaining print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, preferred embodiments of the present invention will be specifically described with reference to the accompanying drawings.

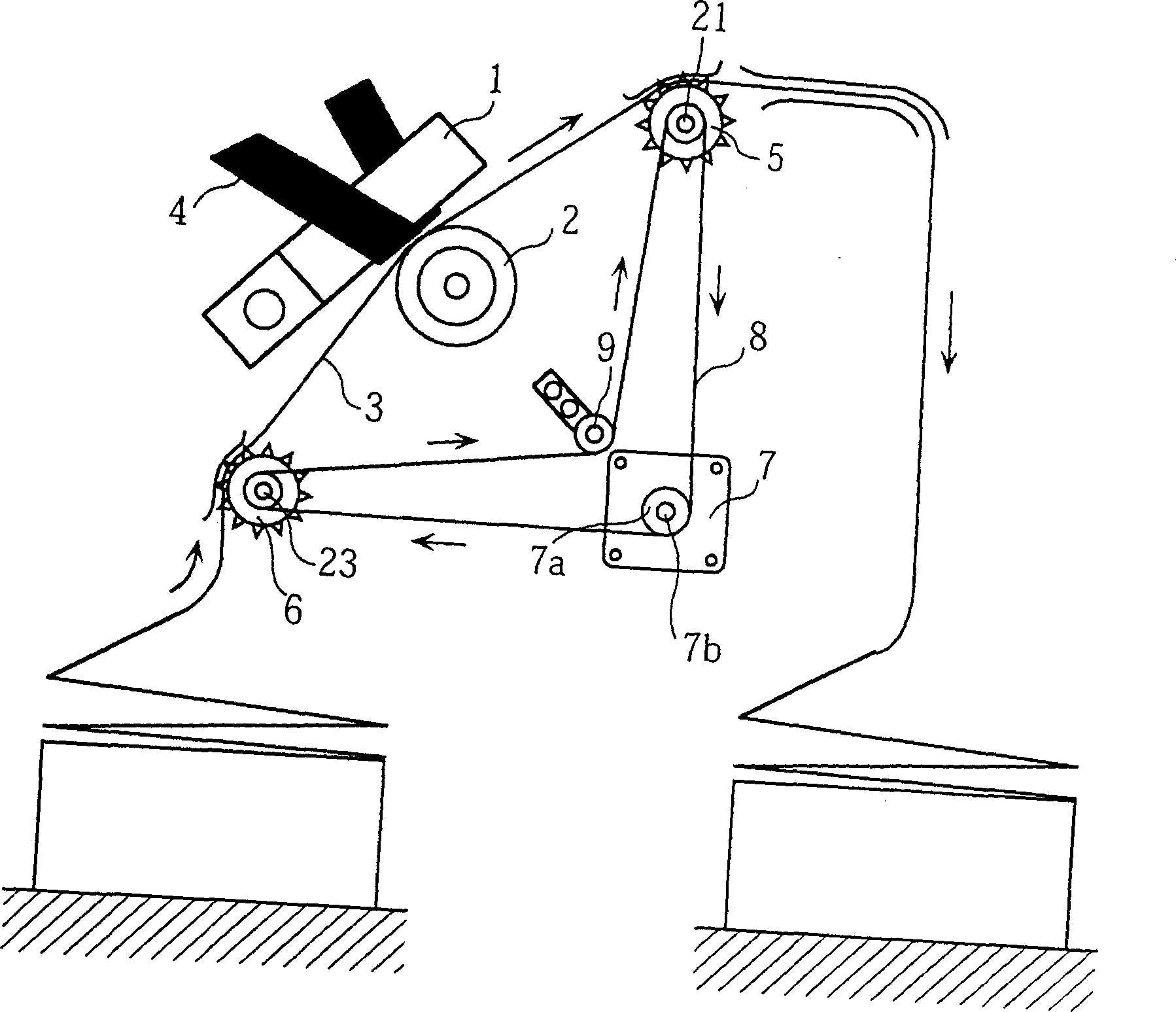

[0039]figure 1 It is a partial schematic side view of an impact printer employing a driving device for a driven body according to the present invention, in which a paper sheet made of continuous paper as a conveyed body is arranged in the gap between the recording head 1 and the platen roller 2 The transport path of the recording paper 3 and the transport path of the ink ribbon 4 . The recording paper 3 is conveyed in the direction of the arrow by the upper paper feeder 5 and the lower paper feeder 6 . The upper paper feeder 5 and the lower paper feeder 6 are rotationally driven by a stepping motor 7 via a pulley 7a and an endless belt 8 mounted on the rotating shaft 7b of the stepping motor 7 . The endless belt 8 adjusts the tension by the belt pulley 9.

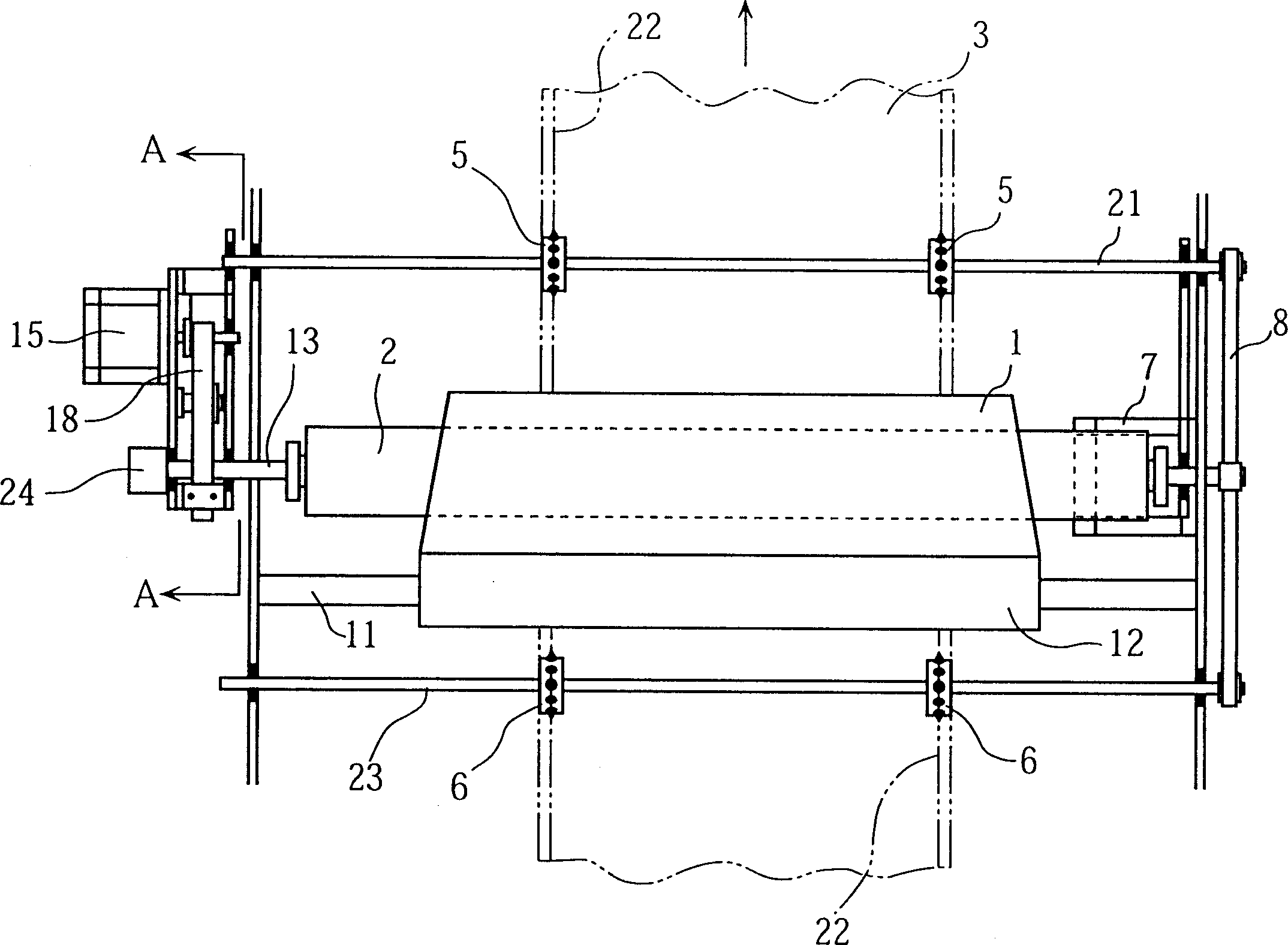

[0040] figure 2 Yes figure 1 A partial schematic top view of an impact pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com