Measuring device and method for three-point bending mechanical properties

A technology of three-point bending and measurement method, which is used in measurement devices, the use of stable bending force to test the strength of materials, and the testing of mechanical parts, etc. The effect of eliminating elongation and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

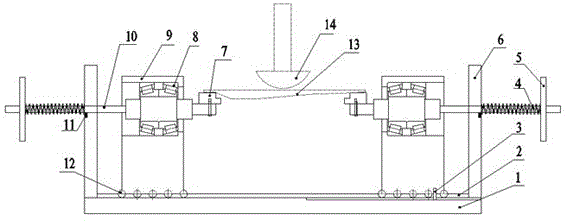

[0022] Such as figure 1 As shown, the multi-shape specimen three-point bending mechanics testing device of the present invention is mainly composed of a support system, a spring preload system, a loading system, and a testing system. It includes base 1, chute 2, displacement sensor 3, spring 4, spring baffle 5, support plate 6, spacer 7, tapered bearing 8, slide seat 9, guide rod 10, lateral load sensor 11, roller 12, loading Indenter 14.

[0023] The pad 7 of the device support system is made of high-strength steel according to the shape of the end face of different samples, and is installed on the guide rod 10 through bolts. The bending test piece 13 is installed and fixed through the pad 7. On the groove 2, the chute 2 is fixedly connected to the base 1, and the two ends of the base 1 are respectively fixedly connected with the support plate 6. In the spring preload system, the guide rod 10 is installed on the sliding seat 9 by the conical bearing 8, and the front end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com