Multi-process, multi-workpiece and double-station fixture for rudder shaft

A multi-workpiece, double-station technology, applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of strict dimensional tolerance requirements, high surface roughness requirements, and difficult processing, so as to reduce equipment usage costs , Reduce labor intensity and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

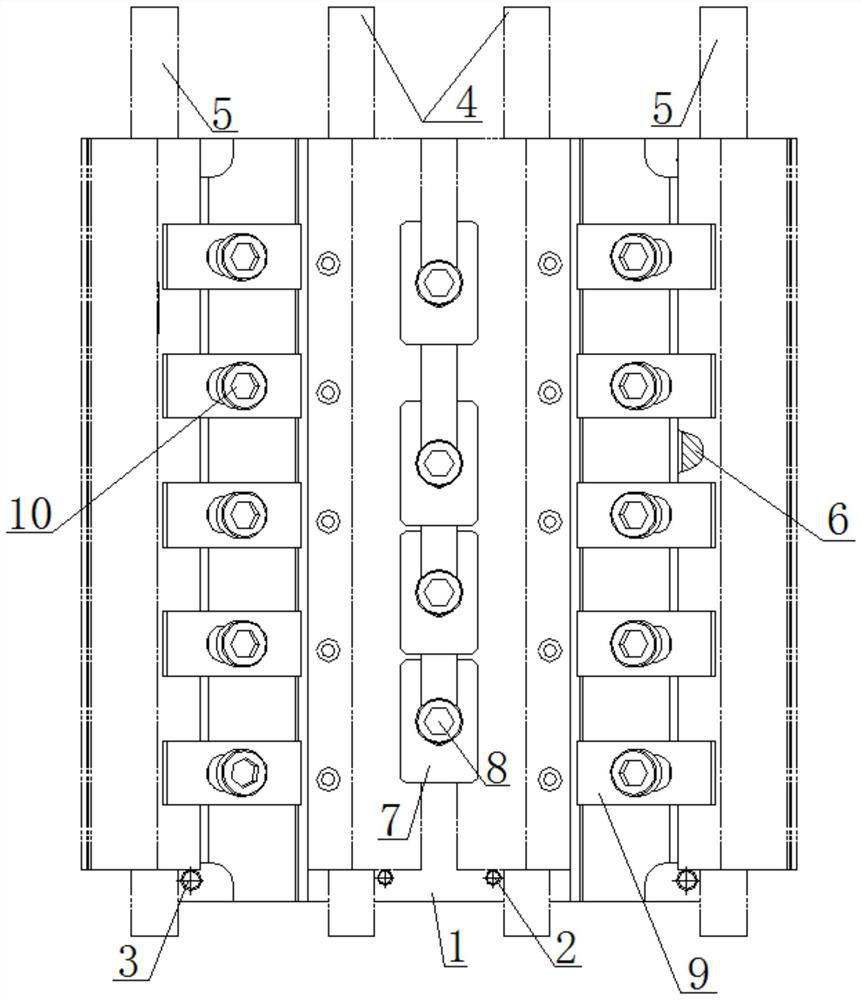

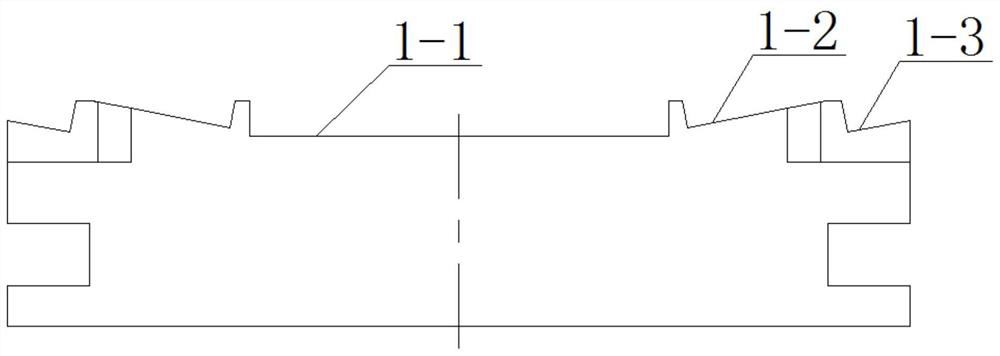

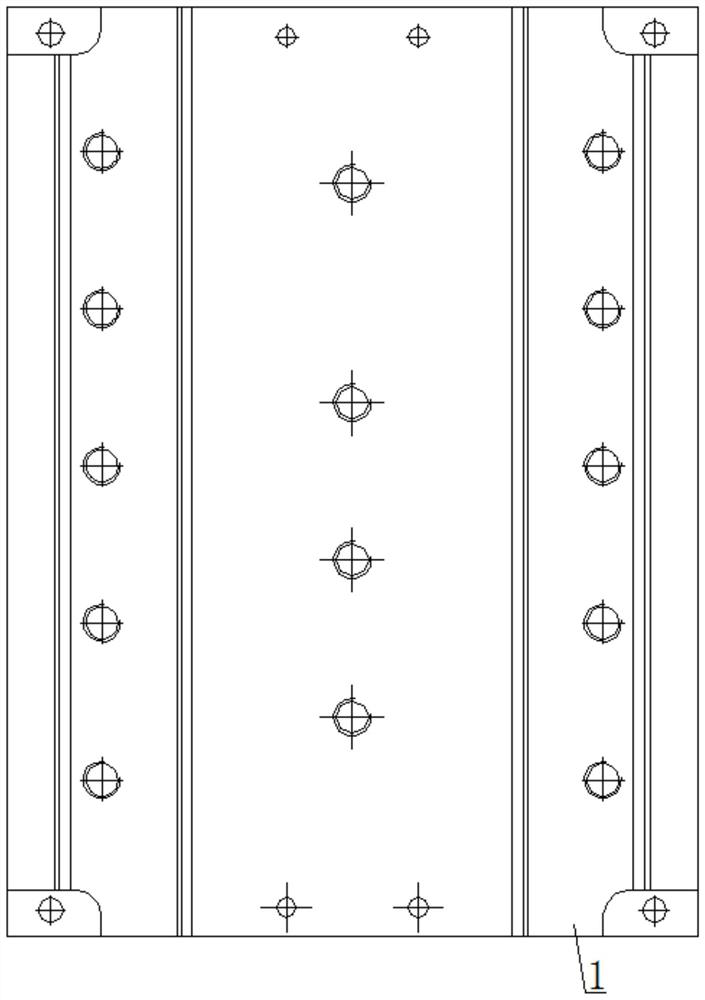

[0022] Specific implementation mode one: combine Figure 1-Figure 7 Describe this embodiment mode, a kind of rudder shaft multi-process, multi-workpiece, double station clamp described in this embodiment mode, it comprises clamp body 1, two first positioning pin shafts 2, two second positioning pin shafts 3, two An inner groove plug block 6, a plurality of U-shaped pressing plates 7, a plurality of first pressing plate connectors 8, a plurality of step pressing plates 9 and a plurality of second pressing plate connecting parts 10; the clip body 1 is a rectangular block, and the top of the rectangular block The surface is processed with a through groove 1-1 along the length direction of the rectangular block, and the side walls on both sides of the through groove 1-1 are sequentially processed with a first stepped slope 1-2 and a second stepped slope 1-3, and the through groove 1-1 The two ends of the groove bottom are respectively symmetrically machined with two first pin shaf...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the first pressure plate connecting piece 8 is a hexagon socket head bolt, the second pressure plate connection piece 10 is a hexagon socket head bolt, and the others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the U-shaped pressing plate 7 is a rectangular plate, and a U-shaped groove is processed on the rectangular plate, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com