Position correcting system of welding robot

A robot system and welding torch technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems that affect welding work efficiency, waste manpower and material resources, etc., shorten the work cycle, improve accuracy and work efficiency, and improve shooting quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, use novel technical scheme to be described in further detail.

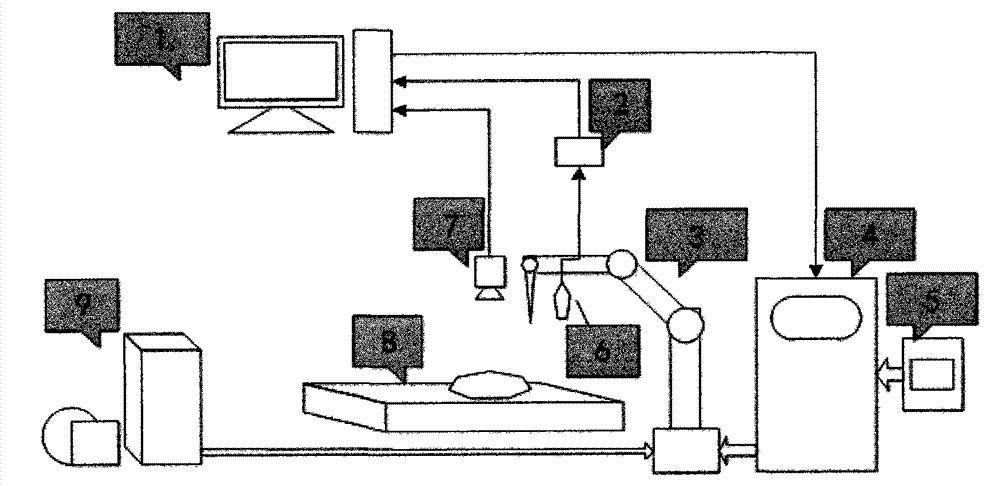

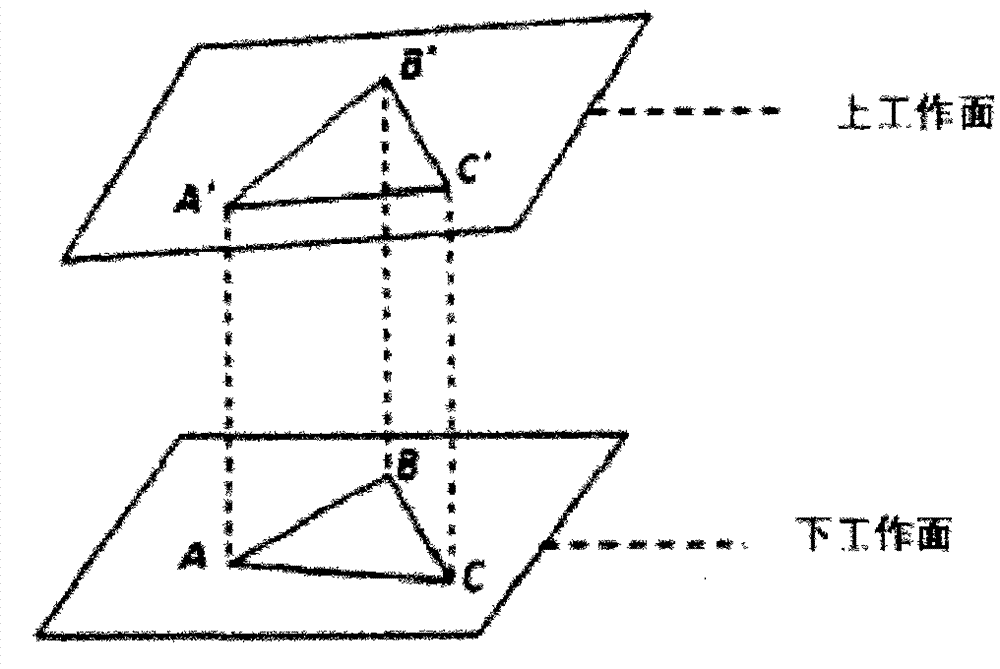

[0020] First, place the workpiece to be welded on the fixture, move three non-collinear points on the original shooting plane through the 6 laser ranging sensors installed on the end of the 3 robot arm, and measure three points to the welding plane The acquired current signal is converted into a digital signal through the 2AD module and transmitted to the 1 industrial control computer; the computer software part analyzes the parallelism of the upper and lower planes according to the obtained information, and transmits the data that needs to be corrected on the camera plane to the 4 robot control cabinet , Adjust the end of the robot arm through the control cabinet so that the shooting plane of the 7 industrial camera is parallel to the welding plane. The plane of the workpiece is photographed by 7 industrial cameras, and the images are sent to 1 industrial con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com