Integral ferrule joint

A ferrule joint, integrated technology, applied in the direction of pipe/pipe joint/pipe fitting, threaded connection, through components, etc., can solve the problems of low installation efficiency, easy leakage, inability to install, etc., to achieve convenient placement and carrying, connection Good reliability and high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

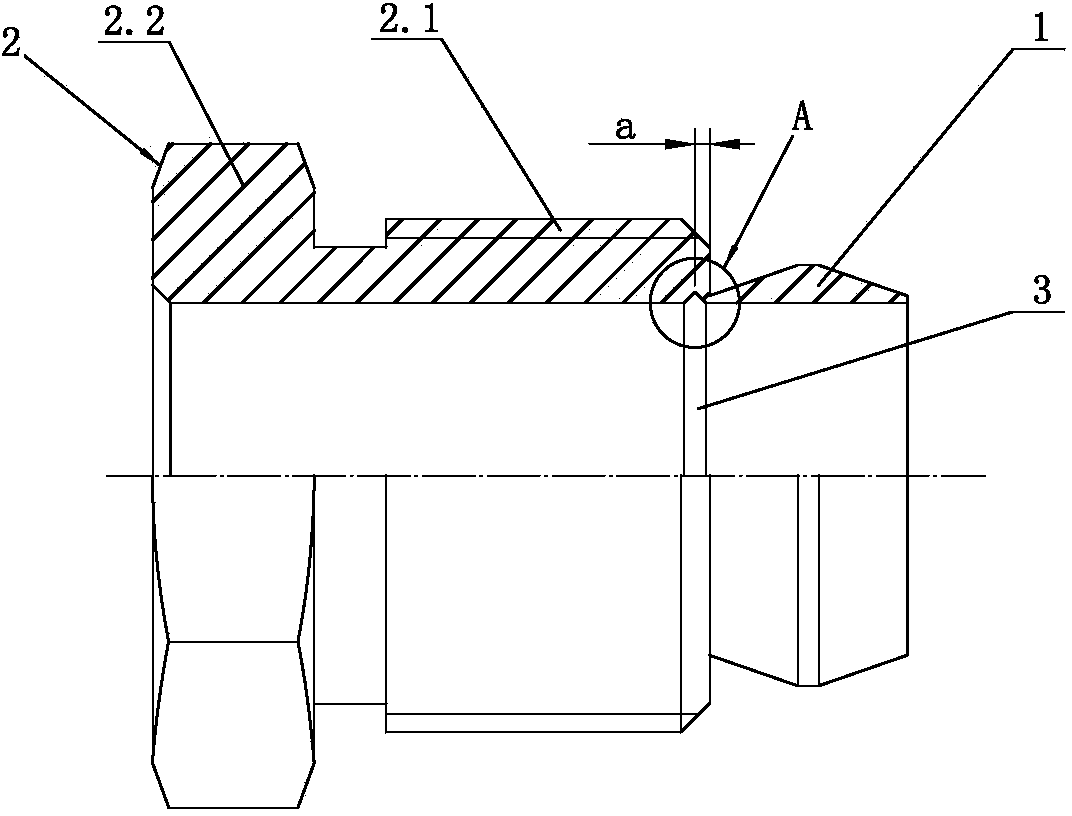

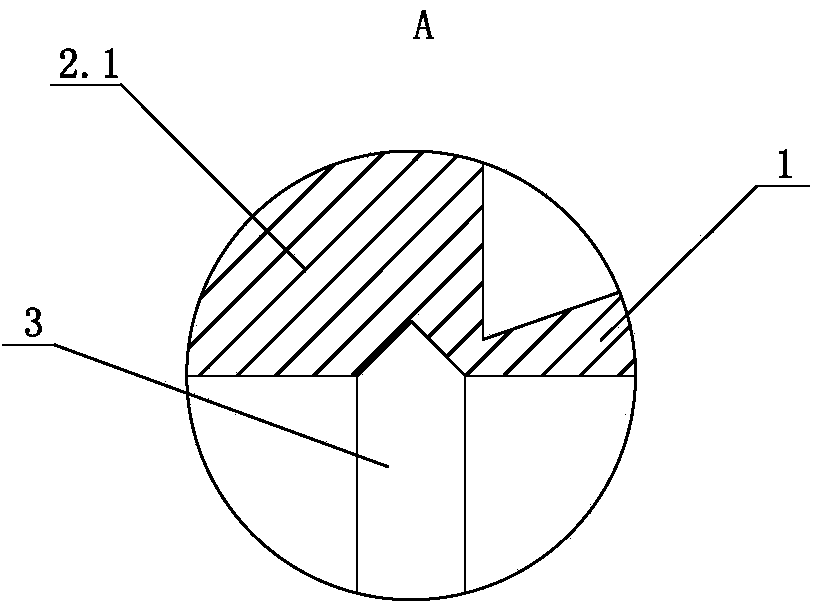

[0019] like figure 1 and figure 2 As shown, an integral ferrule joint with the following structure is provided, which includes a ferrule 1 and a pressure cap 2, the ferrule 1 is a ring structure, the pressure cap 2 is a cylindrical structure, and the pressure cap 2 is divided into threaded Part 2.1 and wrench holding part 2.2, the ferrule 1 is connected to the end position of the threaded part 2.1 and away from the wrench holding part 2.2, the axis of the ferrule 1 is on the same line as the axis of the threaded part 2.1, and The ferrule 1 and the threaded part 2.1 are of an integrated structure. The cross section of the ferrule 1 is a trapezoidal structure, and the inner surface of the ferrule 1 corresponds to the lower side of the trapezoidal structure. Generally, the centerline of the upper side and the lower side of the trapezoidal structure are in the on the same line.

[0020] The inner wall of the threaded part 2.1 near the ferrule 1 is provided with an annular "V"-s...

Embodiment 2

[0025] An integral ferrule joint, which includes a ferrule 1 and a pressure cap 2, the ferrule 1 is a ring structure, the pressure cap 2 is a cylindrical structure, and the pressure cap 2 is divided into a threaded part 2.1 and a wrench clamping part 2.2, the ferrule 1 is connected to the end position of the threaded part 2.1 away from the wrench clamping part 2.2, the axis of the ferrule 1 and the axis of the threaded part 2.1 are on the same straight line, and the ferrule 1 and the threaded part 2.1 are One-piece structure, the cross-section of the ferrule 1 is a trapezoidal structure, and the inner surface of the ferrule 1 corresponds to the lower side of the trapezoidal structure. Generally, the midline of the upper side of the trapezoidal structure is on the same line as the midline of the lower side.

[0026] The inner wall of the threaded part 2.1 near the ferrule 1 is provided with an annular "V"-shaped groove 3, and the diameter corresponding to the bottom of the "V"-s...

Embodiment 3

[0031] An integral ferrule joint with the following structure, which includes a ferrule 1 and a pressure cap 2, the ferrule 1 is a ring structure, the pressure cap 2 is a cylindrical structure, and the pressure cap 2 is divided into a threaded part 2.1 and a wrench The clamping part 2.2, the ferrule 1 is connected to the end position of the threaded part 2.1 away from the wrench clamping part 2.2, the axis of the ferrule 1 and the axis of the threaded part 2.1 are on the same straight line, and the ferrule 1 and the thread Part 2.1 is an integrated structure. The cross-section of the ferrule 1 is a trapezoidal structure, and the inner surface of the ferrule 1 corresponds to the lower side of the trapezoidal structure. Generally, the midline of the upper side of the trapezoidal structure and the midline of the lower side are on the same straight line.

[0032] The inner wall of the threaded part 2.1 near the ferrule 1 is provided with an annular "V"-shaped groove 3, and the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com