Suction type material receiving device, main shaft side material receiving system and auxiliary shaft side material receiving system

A material receiving device and secondary shaft technology, which is applied in metal processing and other directions, can solve the problems of difficult to grasp workpieces, loss of small workpiece blanking, unstable blanking of small workpieces, etc., and achieve the effect of long service life and not easy to lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The application will be described in further detail below in conjunction with the accompanying drawings.

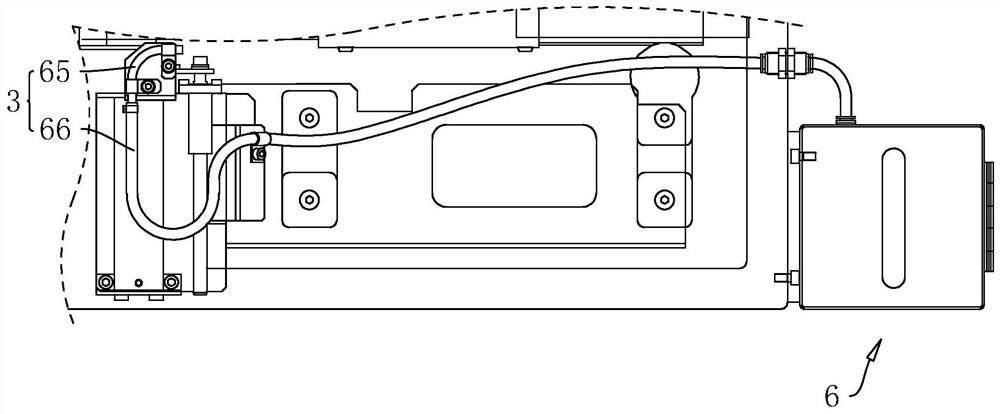

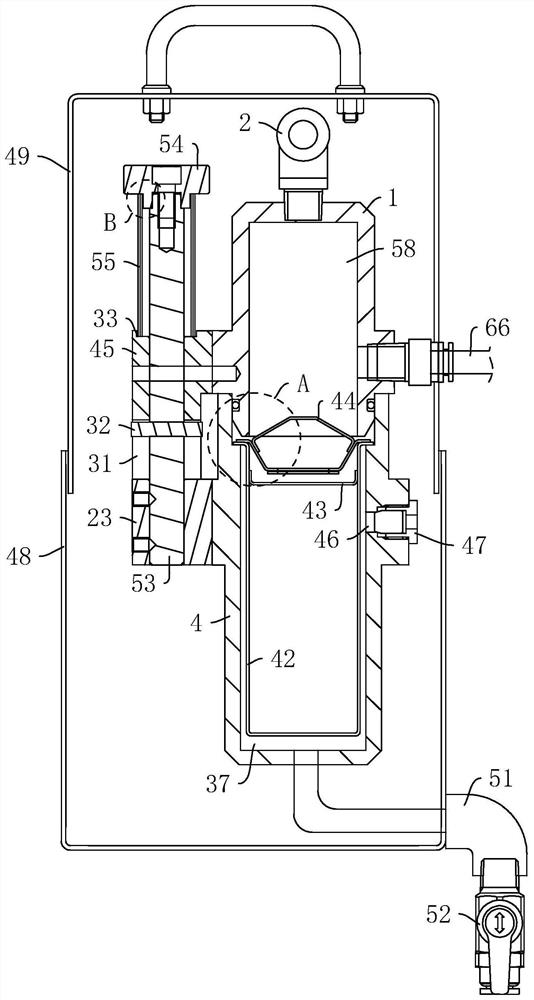

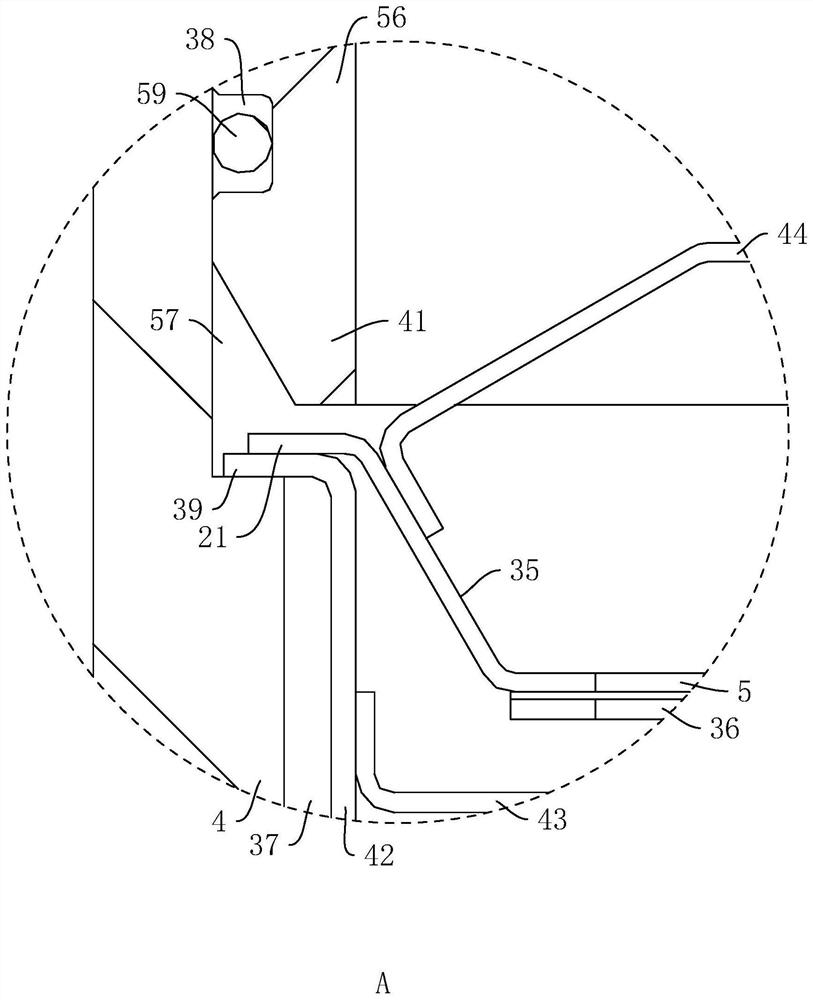

[0043] The embodiment of the present application discloses a suction type material receiving device, referring to figure 1 , including the conveying pipe 3 that is located directly above the machine tool, the conveying pipe 3 includes a hard pipe 65 with one end opening facing the workpiece, the hard pipe 65 is made of a material with higher hardness, such as high carbon steel, so that the first entering The hard tube 65 is not easily deformed. A feeding hose 66 is tightly inserted into the peripheral outer wall of the first entry hard pipe 65 away from the workpiece. The feeding hose 66 can be a transparent PVC hose. , to further make the tight connection between the feeding hose 66 and the initial hard tube 65 .

[0044] refer to figure 1 and figure 2 , the end of the feeding hose 66 far away from the initial hard tube 65 is connected with the receiving bin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com