External spiral rollaway nest forming technology

A forming process and external spiral technology, which is applied in the field of external spiral raceway forming process, can solve the problems that the tooth shape with helix angle cannot be applied, increase the ultra-finishing process, and the processing speed is slow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

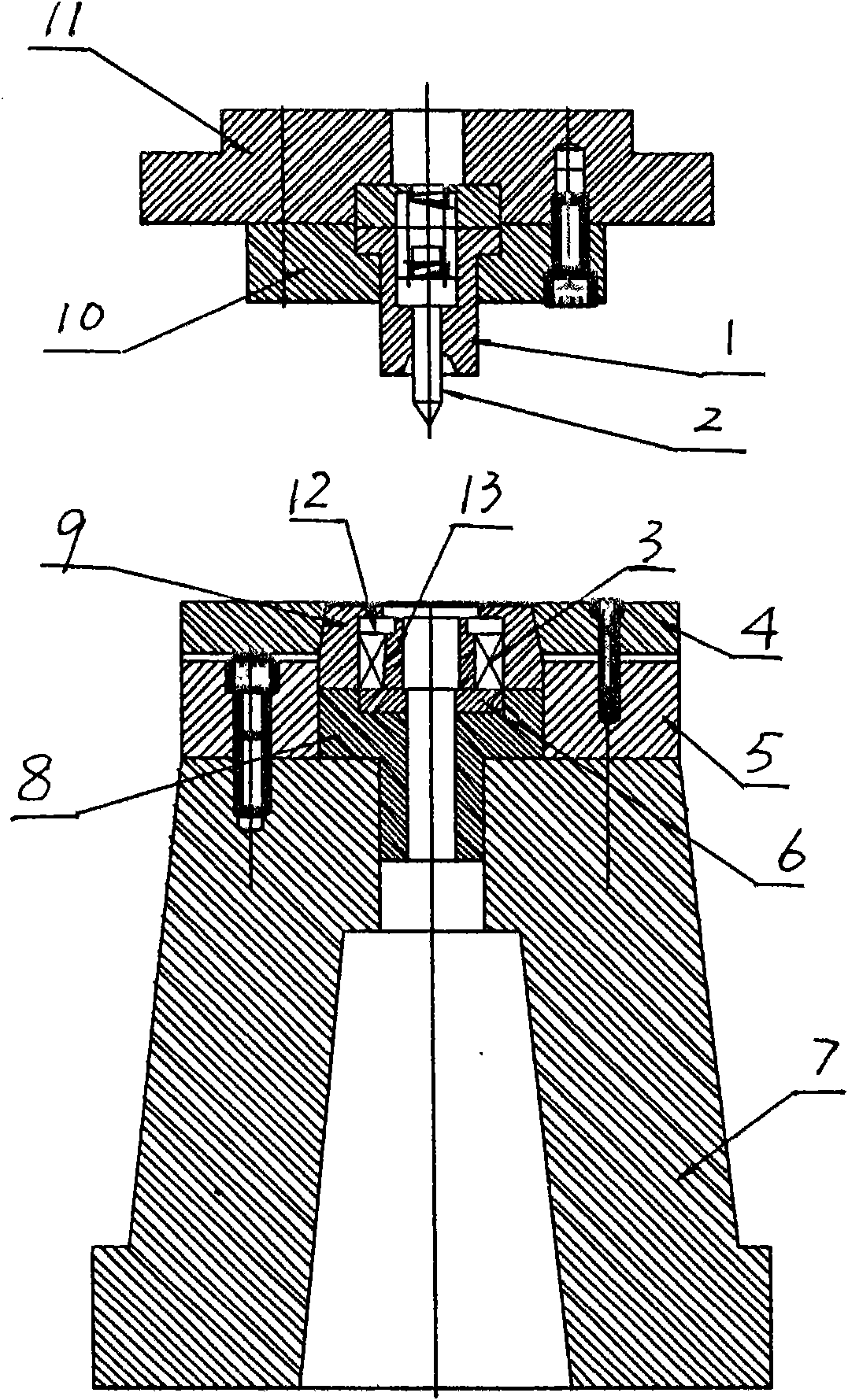

[0006] Below in conjunction with accompanying drawing, the present invention will be further described;

[0007] An outer spiral raceway forming process, mainly including a press, a top, a punch, a punch fixing plate, an upper fixing plate, a rotating die, a die fixing part, a base, a rolling thrust bearing, a sliding bearing, and a sliding backing plate etc. It is characterized in that: Put the pre-treated workpiece into the entrance of the die, start the press, use the upper tip to withstand the center hole of the workpiece and position it, and then start to press in. At the beginning of extrusion, the axial press The input force can cause the die to generate a circumferential tangential component force, and the workpiece can gradually establish a rotary extrusion mechanism when it goes down; the stage from the beginning of extrusion to the blank being extruded into the shaping area is the transitional extrusion stage, and then passes through the shaping stage , the blank is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com