Miniaturized handheld deep and small hole compound deburring device

A technology for removing burrs and deep holes, applied in the field of mechanical processing tools, can solve the problems of difficult removal, high cost, unfavorable flexibility of assembly line operations, etc., and achieve the effect of eliminating processing marks and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

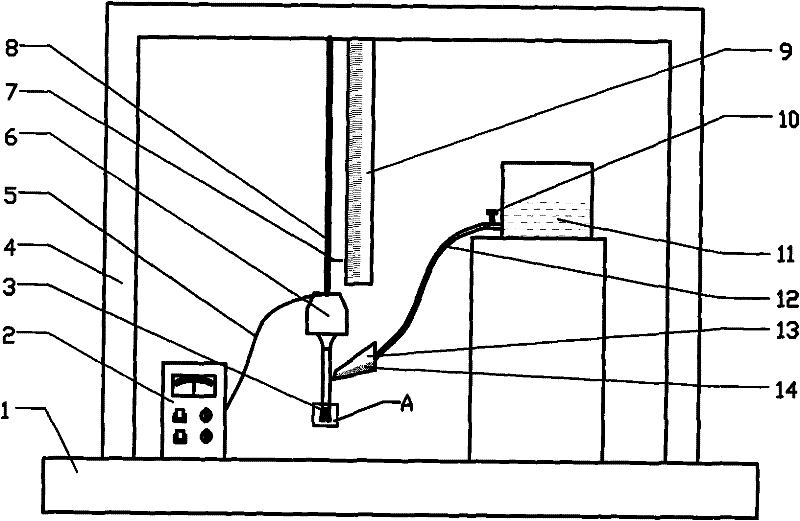

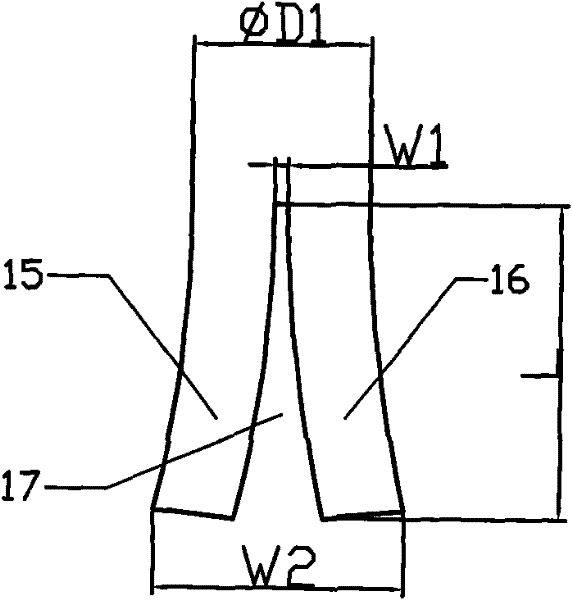

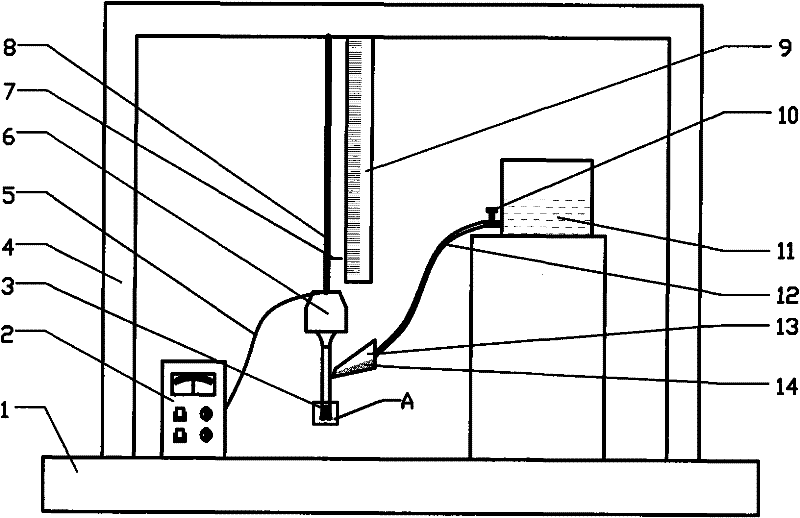

[0012] Design of the deburring tool:

[0013] The deburring tool is a cylindrical elongated metal rod made of tool steel. Its diameter ФD1 is Ф0.2mm smaller than the diameter of the small hole to be deburred. There is a transparent opening rectangular groove 17 in the center of the front end of the deburring tool, and the transparent opening rectangular groove is centered relative to the outer circle of the metal rod. The width W1 of the transparent open rectangular groove is 0.25 mm to 0.3 mm, and the depth L of the rectangular groove is 3 to 5 times the diameter of the metal rod ΦD1. Due to the existence of the transparent opening rectangular groove 17, the two branch parts 15, 16 formed at the front end of the metal rod will naturally have a certain arc of bending deformation, and because the transparent opening rectangular groove is divided relative to the outer circle of the metal rod, the two The bending deformation of the two branch parts is exactly the same and has e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com