Cutting method of chromium-molybdenum stainless steel composite layer

A cutting method and technology of stainless steel layer, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of cutting interruption, poor fluidity, and high melting point of oxides, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this case, the cylinder uses 12Cr2Mo1R as the base layer and has a thickness of 100mm. The internal surfacing is welded with 6.5mm 347 series stainless steel. The cylinder is opened by the following cutting method.

[0032] (1) Cutting material:

[0033] Oxygen: industrial oxygen, purity 99.2wt%, impurity content 0.02wt%, bottled pressure 10MPa, cutting pressure 0.7MPa;

[0034] Propane: bottled pressure 1.6MPa, cutting pressure 0.05MPa;

[0035] Cutting gun: shooting suction type G01-300; cutting nozzle: plum blossom 3#.

[0036] (2) Cutting method:

[0037] 1) Start cutting from the Cr-Mo steel side, and use an oxidizing flame to preheat the cutting position before the first cutting process. When the cutting temperature (1300°C) is reached, the high-pressure oxygen valve is gradually opened.

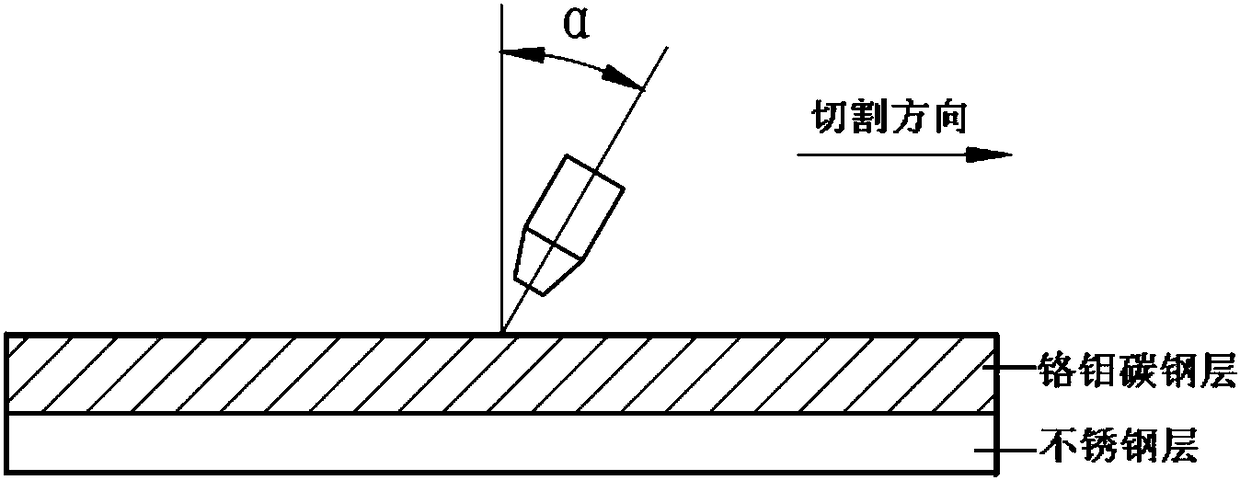

[0038] 2) Tilt the cutting torch 30° to the length of the incision for the first cutting process to form the incision so that the molten metal and oxide flow out evenly in the opposite d...

Embodiment 2

[0041] A: In this case, the cylinder uses 12Cr2Mo1R as the base layer and has a thickness of 100mm. The internal surfacing is welded with 6.5mm 347 series stainless steel. The cylinder is opened by the following cutting method.

[0042] (1) Cutting material:

[0043] Oxygen: industrial oxygen, purity 99.2wt%, impurity content 0.02wt%, bottled pressure 10MPa, cutting pressure 0.7MPa;

[0044] Propane: bottled pressure 1.6MPa, cutting pressure 0.05MPa;

[0045] Cutting gun: shooting suction type G01-300; cutting nozzle: plum blossom 3#.

[0046] (2) Cutting method:

[0047] 1) Start cutting from the Cr-Mo steel side, and use an oxidizing flame to preheat the cutting position before the first cutting process. When the cutting temperature (1300°C) is reached, the high-pressure oxygen valve is gradually opened.

[0048] 2) Tilt the cutting torch 30° to the length of the incision for the first cutting process to form the incision so that the molten metal and oxide flow out evenly in the opposit...

Embodiment 3

[0061] A: In this case, the cylinder uses 12Cr2Mo1R as the base layer and has a thickness of 100mm. The internal surfacing is welded with 6.5mm 347 series stainless steel. The cylinder is opened by the following cutting method.

[0062] (1) Cutting material:

[0063] Oxygen: industrial oxygen, purity 99.2wt%, impurity content 0.02wt%, bottled pressure 10MPa, cutting pressure 0.7MPa;

[0064] Propane: bottled pressure 1.6MPa, cutting pressure 0.05MPa;

[0065] Cutting gun: shooting suction type G01-300; cutting nozzle: plum blossom 3#.

[0066] (2) Cutting method:

[0067] 1) Start cutting from the Cr-Mo steel side, and use an oxidizing flame to preheat the cutting position before the first cutting process. When the cutting temperature (1300°C) is reached, the high-pressure oxygen valve is gradually opened.

[0068] 2) Tilt the cutting gun by 10° to the length of the incision and swing the cutting gun for the first cutting process to form the incision so that the molten metal and oxide flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com