Super-hydrophobic paint surface fast wax and preparation method thereof

A super-hydrophobic and paint surface technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of non-directional arrangement of molecules, low hydrophobicity, and labor-consuming, etc., to achieve long protection time, saving labor hours, and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

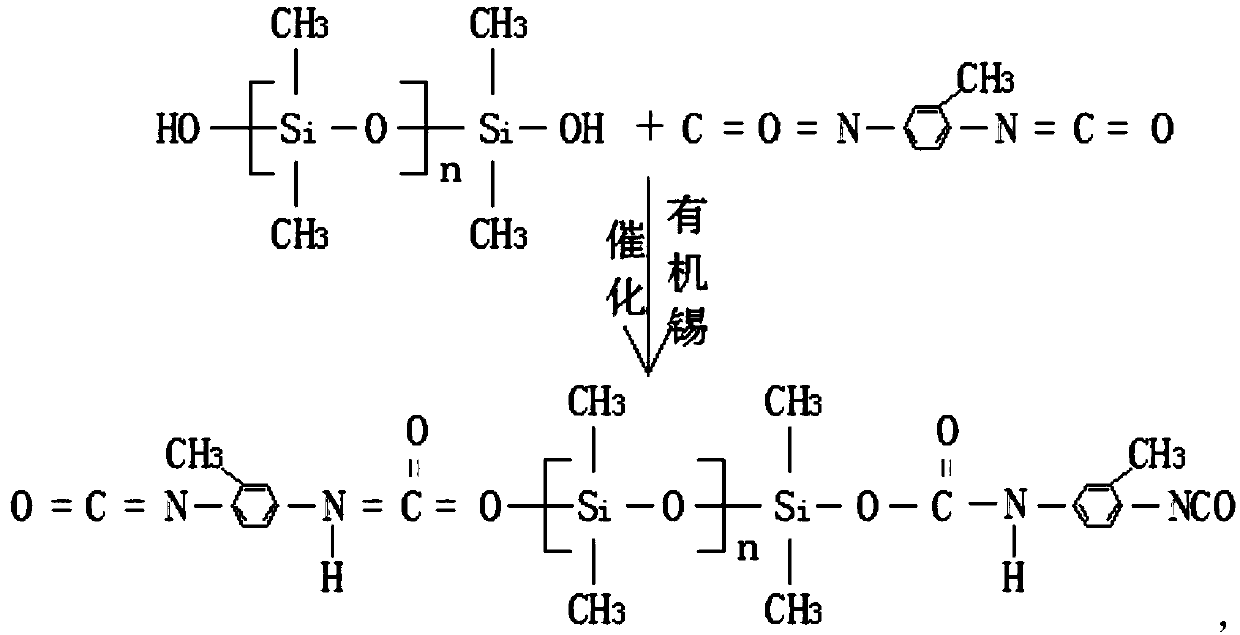

Embodiment 1

[0029] A kind of super-hydrophobic paint surface fast wax, is made of the following components by weight percentage: synthetic resin 30%, water 63%, SP-80 emulsifier 3%, ultraviolet absorber 4%, described synthetic resin is made of the following weight percentage Component composition: 85% of hydroxyl silicone oil with a viscosity of 700cps, 14% of toluene diisocyanate, and 1% of dibutyltin dilaurate. When preparing the superhydrophobic paint quick wax, the specific steps are as follows:

[0030] 1) Take the above-mentioned hydroxy silicone oil, add anhydrous sodium sulfate of the same quality as the hydroxy silicone oil to the hydroxy silicone oil, stir and let stand, remove the upper layer, and obtain dehydrated hydroxy silicone oil;

[0031] 2) Add dehydrated silicone oil into the reaction kettle, slowly add toluene diisocyanate and dibutyltin dilaurate under the protection of nitrogen, the whole adding process is controlled within 30 minutes, start the stirrer, stir for 4 ...

Embodiment 2

[0036] A kind of super-hydrophobic paint surface fast wax, is made of the following components by weight percentage: synthetic resin 40%, water 50%, SP-80 emulsifier 5%, ultraviolet absorber 5%, described synthetic resin is made of the following weight percentage Component composition: 89% of hydroxyl silicone oil with a viscosity of 700cps, 10% of toluene diisocyanate, and 1% of dibutyltin dilaurate. When preparing the superhydrophobic paint quick wax, the specific steps are as follows:

[0037] 1) Take the above-mentioned hydroxy silicone oil, add anhydrous sodium sulfate of the same quality as the hydroxy silicone oil to the hydroxy silicone oil, stir and let stand, remove the upper layer, and obtain dehydrated hydroxy silicone oil;

[0038] 2) Add dehydrated silicone oil into the reaction kettle, slowly add toluene diisocyanate and dibutyltin dilaurate under the protection of nitrogen, the whole adding process is controlled within 30 minutes, start the stirrer, stir for 4 ...

Embodiment 3

[0043] A kind of superhydrophobic fast wax for paint surface of the present invention is made of the following components by weight percentage: 35% of synthetic resin, 55% of water, 5% of SP-80 emulsifier, 5% of ultraviolet absorber, wherein, the synthetic resin It consists of the following components in weight percent: 87% of hydroxyl silicone oil with a viscosity of 700cps, 12% of toluene diisocyanate, and 1% of dibutyltin dilaurate. When preparing the superhydrophobic paint quick wax, the specific steps are as follows:

[0044] 1) Take the above-mentioned hydroxy silicone oil, add anhydrous sodium sulfate of the same quality as the hydroxy silicone oil to the hydroxy silicone oil, stir and let stand, remove the upper layer, and obtain dehydrated hydroxy silicone oil;

[0045] 2) Add dehydrated silicone oil into the reaction kettle, slowly add toluene diisocyanate and dibutyltin dilaurate under the protection of nitrogen, the whole adding process is controlled within 30 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com