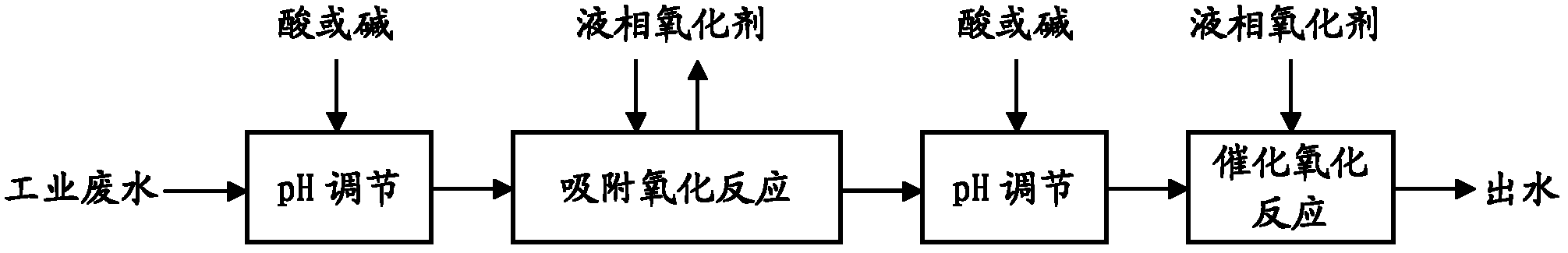

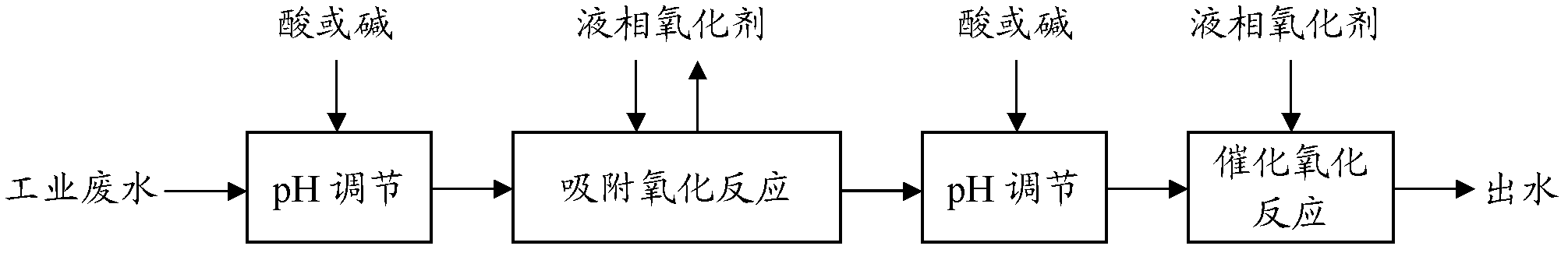

Industrial wastewater decoloring treatment process

A technology for treating process and industrial wastewater, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. , the problem of high cost of adsorbent regeneration, to achieve the effect of eliminating resin desorption and regeneration, improving oxidative decolorization efficiency and improving reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

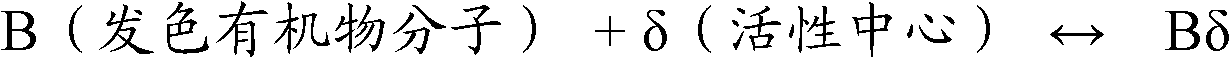

[0035] Adjust the pH of pharmaceutical wastewater, and input it into the adsorption oxidation reactor filled with NKA-9 polar macroporous adsorption resin (manufacturer: Nankai University Chemical Factory), a large amount of color-forming organic matter is adsorbed in the resin, when the chromaticity removal rate is less than 60% When draining water, add H to the adsorbent resin 2 o 2 , carry out oxidative decolorization, and activate the regenerated resin at the same time; the effluent of the adsorption oxidation reactor adjusts the pH and then enters the catalytic oxidation reactor, which is filled with the adsorption resin loaded with copper oxide, and added H 2 o 2 , carry out catalytic oxidation decolorization, and remove small molecules and non-polar chromogenic organic substances that are difficult to adsorb in the adsorption oxidation unit.

[0036] Wastewater influent water quality: chromaticity is 5000 times;

Embodiment 2

[0047] Adjust the pH of printing and dyeing wastewater, and input it into the adsorption oxidation reactor filled with NKA-II polar macroporous adsorption resin (manufacturer: Nankai University Chemical Factory), a large amount of color-forming organic matter is adsorbed in the resin, when the chromaticity removal rate is less than 60% When draining water, add ClO to the adsorption resin 2 Solution, carry out oxidative decolorization, and activate the regeneration resin at the same time; The effluent of the adsorption oxidation reactor enters the catalytic oxidation reactor, and the adsorption resin loaded with nickel oxide is filled in the reactor, and ClO is added 2 Solution, decolorization by catalytic oxidation, removal of small molecules and non-polar chromogenic organic substances that are difficult to adsorb by the adsorption oxidation unit.

[0048] Wastewater influent water quality: chromaticity is 1000 times;

[0049] Adsorption Oxidation Reactor ClO 2 Dosage: 0.2kg / ...

Embodiment 3

[0059] Adjust the pH of coking wastewater, and input it into the adsorption oxidation reactor filled with HPD400 polar macroporous adsorption resin (manufacturer: Cangzhou Baoen Chemical Co., Ltd.), a large amount of chromogenic organic matter is adsorbed in the resin, when the chromaticity removal rate is less than 60 % when draining water, add H to the adsorption resin 2 o 2 , carry out oxidative decolorization, and activate the regenerated resin at the same time; the effluent of the adsorption oxidation reactor adjusts the pH and then enters the catalytic oxidation reactor. 2 o 2 , carry out catalytic oxidation decolorization, and remove small molecules and non-polar chromogenic organic substances that are difficult to adsorb in the adsorption oxidation unit.

[0060] Wastewater influent water quality: chromaticity is 3000 times;

[0061] Adsorption Oxidation Reactor H 2 o 2 Dosage: 0.3kg / m 3 waste water;

[0062] Catalytic Oxidation Reactor H 2 o 2 Dosage: 0.2kg / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com