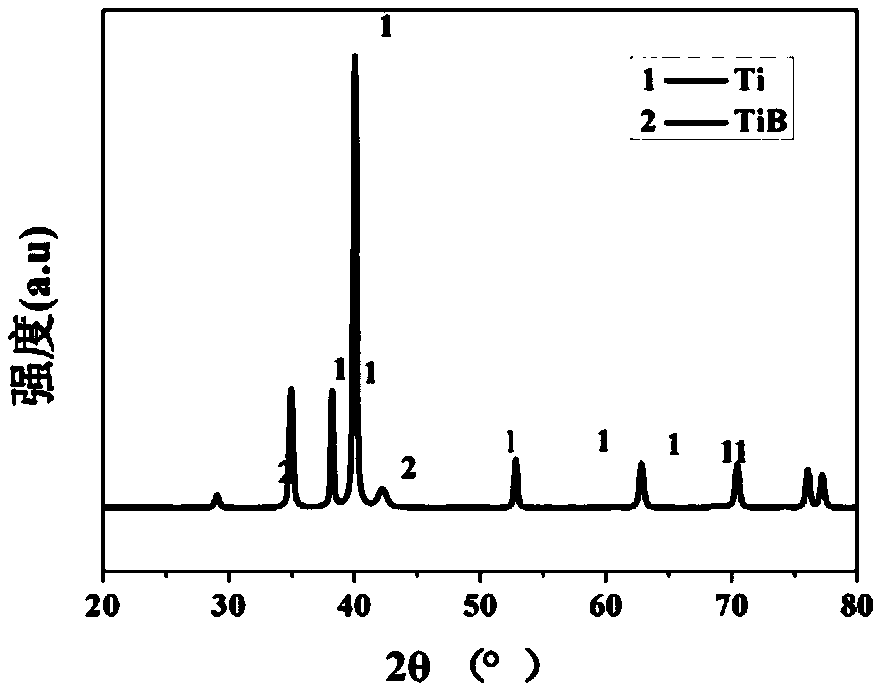

3D printing high-compactness titanium-titanium boride composite material and preparation method thereof

A composite material and 3D printing technology, which is applied in the field of titanium-titanium boride composite materials, can solve the problems of poor mechanical properties of Ti-TiB composite materials, easy introduction of impurities, laser power, and low density of composite materials, and achieve uniform dispersion The effect of high reliability, abundant resources, and no need for molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A 3D printing high-density titanium-titanium boride composite material and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0034] Step 1, with the titanium powder body of 45~53wt% and the titanium diboride powder body of 47~55wt% as raw material, mix, obtain raw material powder; Then press described raw material powder: the mass ratio of agate ball is 1: (1 ~5), the raw material powder and the agate balls are placed in a mixer mill, and mixed for 1-6 hours to obtain titanium-titanium diboride powder.

[0035] Step 2. Manually spread the titanium-titanium diboride powder on the substrate of the 3D printing device according to the set powder coating thickness of each layer, vacuumize to -0.1MPa, and pass in circulating argon gas; HUST 3DP software in the computer, select the designed 3D model, then turn on the laser in the 3D printing device, manually control the first layer of laser scanning, the first layer of laser...

Embodiment 2

[0040] A 3D printing high-density titanium-titanium boride composite material and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0041] Step 1, with the titanium powder body of 52~61wt% and the titanium diboride powder body of 39~48wt% as raw material, mix, obtain raw material powder; Then press described raw material powder: the mass ratio of agate ball is 1: (1 ~5), the raw material powder and the agate balls are placed in a mixer mill, and mixed for 1-6 hours to obtain titanium-titanium diboride powder.

[0042] Step 2. Manually spread the titanium-titanium diboride powder on the substrate of the 3D printing device according to the set powder coating thickness of each layer, vacuumize to -0.1MPa, and pass in circulating argon gas; HUST 3DP software in the computer, select the designed 3D model, then turn on the laser in the 3D printing device, manually control the first layer of laser scanning, the first layer of laser...

Embodiment 3

[0047] A 3D printing high-density titanium-titanium boride composite material and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0048] Step 1, with the titanium powder body of 60~69wt% and the titanium diboride powder body of 31~40wt% as raw material, mix, obtain raw material powder; Then press described raw material powder: the mass ratio of agate ball is 1: (1 ~5), the raw material powder and the agate balls are placed in a mixer mill, and mixed for 1-6 hours to obtain titanium-titanium diboride powder.

[0049] Step 2. Manually spread the titanium-titanium diboride powder on the substrate of the 3D printing device according to the set powder coating thickness of each layer, vacuumize to -0.1MPa, and pass in circulating argon gas; HUST 3DP software in the computer, select the designed 3D model, then turn on the laser in the 3D printing device, manually control the first layer of laser scanning, the first layer of laser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com