Organic silicon rubber composite tackifier and preparation method thereof

A silicone rubber and composite technology, applied in the direction of adhesive additives, polymer adhesive additives, etc., can solve the problems of time-consuming, labor-intensive surface treatment, increased risk, toxicity, etc., and save the pretreatment process and materials , excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

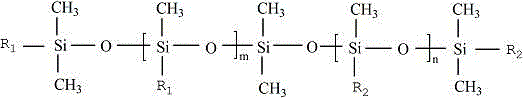

[0025] Embodiment one: First, mix epoxy silane and vinyl silane at a ratio of 1:1.5 and react with a platinum catalyst at a temperature of 150°C for 4 hours, then lower the temperature to 80°C, and remove small molecules and untreated compounds under reduced pressure. The reacted silane is obtained as an intermediate containing an epoxy group structure; after mixing acryloyloxysilane and vinyl silane at a ratio of 1:1.5, the reaction is carried out under a platinum catalyst at a temperature of 100°C for 6 hours, and then Lower the temperature to 80°C, remove small molecules and unreacted silane under reduced pressure to obtain an intermediate containing an acryloyloxy structure; The intermediate is mixed at a ratio of 1:1, and this mixture is mixed with silicone oil. The chemical formula of the silicone oil is:

[0026]

[0027] Where: R 1 : Methyl, Vinyl, Hydroxyl

[0028] R 2 : methyl, vinyl, hydrogen

[0029] After mixing at a ratio of 1:1.2, react at a temp...

Embodiment 2

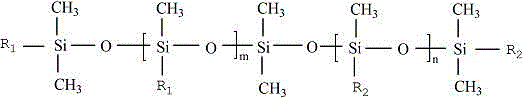

[0030] Embodiment two : First, mix epoxy silane and vinyl silane with a ratio of 1:1.55, then react at 160°C under a platinum catalyst for 4.5 hours, then cool down to 80°C, remove small molecules and Unreacted silane, to obtain an intermediate containing epoxy group structure; mix acryloyloxysilane and vinylsilane at a ratio of 1:1.55, and then react at a temperature of 120°C under a platinum catalyst for 8 hours. After cooling down to 80°C, remove small molecules and unreacted silanes under reduced pressure to obtain intermediates containing acryloyloxy groups; then combine the intermediates containing epoxy groups obtained in the above steps with acryloyloxy The intermediate of the structure is mixed at a ratio of 1:1, and the mixture is mixed with silicone oil. The chemical formula of the silicone oil is:

[0031]

[0032] Where: R 1 : Methyl, Vinyl, Hydroxyl

[0033] R 2 : methyl, vinyl, hydrogen

[0034] After mixing at a ratio of 1:1.3, react at a tempera...

Embodiment 3

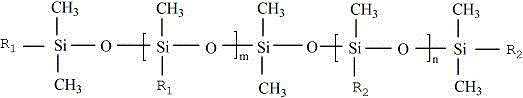

[0035] Embodiment Three : First, mix epoxy silane and vinyl silane with a ratio of 1:1.52, then react at a temperature of 155°C under a platinum catalyst for 4.3 hours, then cool down to 80°C, and remove small molecules and Unreacted silane, to obtain an intermediate containing an epoxy group structure; mix acryloyloxysilane and vinyl silane at a material ratio of 1:1.52, and then react at a temperature of 110°C under a platinum catalyst for 7 hours. After cooling down to 80°C, remove small molecules and unreacted silanes under reduced pressure to obtain intermediates containing acryloyloxy groups; then combine the intermediates containing epoxy groups obtained in the above steps with acryloyloxy The intermediate of the structure is mixed at a ratio of 1:1, and the mixture is mixed with silicone oil. The chemical formula of the silicone oil is:

[0036]

[0037] Where: R 1 : Methyl, Vinyl, Hydroxyl

[0038] R 2 : methyl, vinyl, hydrogen

[0039] After mixing at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com