High-strength glass-ceramic and preparation method thereof

A glass-ceramic, high-strength technology, applied in glass manufacturing equipment, glass forming, glass rolling, etc., can solve the problems of small space for glass-ceramics, inhibit the development of glass-ceramics, and high surface porosity. Good consistency, excellent physical and chemical properties, good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

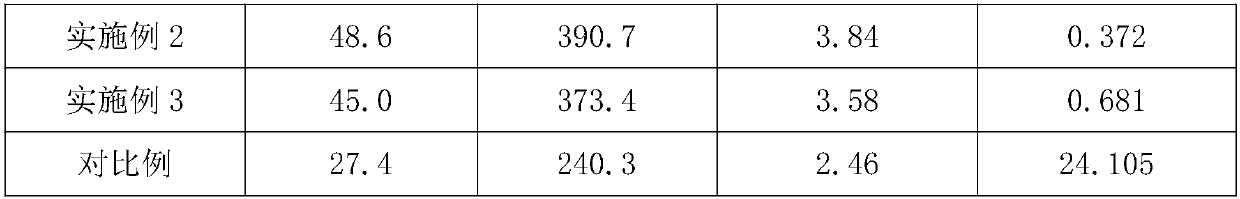

Examples

Embodiment 1

[0033] A high-strength glass-ceramic, the following raw materials are prepared: cullet 120kg, modified quartz powder 60kg, tremolite 10kg, mordenite 10kg, nano-scale silicon dioxide 15kg, brucite fiber 5kg, sodium borosilicate 2kg, 3kg sodium metasilicate pentahydrate, 2kg calcium aluminosilicate, 1kg boron oxide, 1kg ammonium nitrate, 1kg cerium oxide and 1kg calcium fluoride;

[0034] Above-mentioned modified quartz powder is made through the following steps:

[0035] 1) First take 60kg of quartz stone and crush and grind it to a 20-mesh sieve to obtain quartz powder;

[0036] 2) Transfer the above-mentioned quartz powder to a drying box, preheat and dry it at a temperature of 105° C. for 1 hour, and then add it to an ammonia solution with a mass percentage of 8% of the quartz powder and a concentration of 25%. Stir at ℃ for 2h, filter out the quartz powder;

[0037] 3) then to step 2) in the filtered quartz powder, add the azidosilane coupling agent S-3046 equivalent to 3...

Embodiment 2

[0047] A high-strength glass-ceramic, the following raw materials are prepared: cullet 140kg, modified quartz powder 70kg, tremolite 15kg, mordenite 15kg, nano-scale silicon dioxide 20kg, brucite fiber 10kg, sodium borosilicate 4kg, 4kg sodium metasilicate pentahydrate, 3kg calcium aluminosilicate, 5kg boron oxide, 5kg ammonium nitrate, 5kg cerium dioxide and 2kg calcium fluoride;

[0048] Above-mentioned modified quartz powder is made through the following steps:

[0049] 1) First take 70kg of quartz stone and crush and grind it to a 30-mesh sieve to obtain quartz powder;

[0050]2) Transport the above-mentioned quartz powder to a drying box, preheat and dry it at a temperature of 115° C. for 1.5 hours, and then add it to an ammonia solution with a mass percentage of 10% of the quartz powder and a concentration of 25%. Stir at 70°C for 2.5 hours, filter out the quartz powder;

[0051] 3) then to step 2) in the filtered quartz powder, add the azidosilane coupling agent S-304...

Embodiment 3

[0061] A high-strength glass-ceramic, the following raw materials are prepared: cullet 160kg, modified quartz powder 80kg, tremolite 20kg, mordenite 20kg, nano-scale silicon dioxide 25kg, brucite fiber 15kg, sodium borosilicate 6kg, Sodium metasilicate pentahydrate 5kg, calcium aluminosilicate 4kg, boron oxide 10kg, ammonium nitrate 10kg, cerium dioxide 10kg and calcium fluoride 3kg;

[0062] Above-mentioned modified quartz powder is made through the following steps:

[0063] 1) First take 80kg of quartz stone and crush and grind it to a 40-mesh sieve to obtain quartz powder;

[0064] 2) Transfer the above-mentioned quartz powder to a drying box, preheat and dry it at a temperature of 125°C for 2 hours, and then add it to an ammonia solution with a mass percentage of 12% of the quartz powder and a concentration of 25%. Stir at ℃ for 3h, filter out the quartz powder;

[0065] 3) then to step 2) in the filtered quartz powder, add the azidosilane coupling agent S-3046 equivalen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com