Patents

Literature

94results about How to "High flexural and compressive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick-setting cement-based capillary crystalline self-repairing waterproofing material and preparation method therefor

ActiveCN106946518AAchieve waterproof effectImprove flexural and compressive capacityIon contentBULK ACTIVE INGREDIENT

The invention discloses a quick-setting cement-based capillary crystalline self-repairing waterproofing material and a preparation method therefor. The quick-setting cement-based capillary crystalline self-repairing waterproofing material is prepared from the following ingredients in parts by weight: 55-75 parts of silicate cement, 25-45 parts of quartz sand, 3-10 parts of buffering agent, 4-12 parts of active ingredient A, 4-15 parts of active ingredient B, 2-6 parts of expanding agent, 1-12 parts of calcium ion supplement and 1-4 parts of water reducing agent. The waterproofing material disclosed by the invention is prepared by a simple physical mixing method, is short in initial setting time and low in chloride ion content and can infiltrate into the interior of a cement-based material to form crystals so as to block up microcracks, thus, the folding and compressing resistance and secondary infiltrating resistance are improved, and meanwhile, the cement-based material is endowed with long-lasting self-repairing performance and good waterproof and durable performance. In addition, the preparation method for the quick-setting cement-based capillary crystalline self-repairing waterproofing material is simple, has low requirements on equipment and processes and has very high application power.

Owner:SOUTH CHINA UNIV OF TECH +1

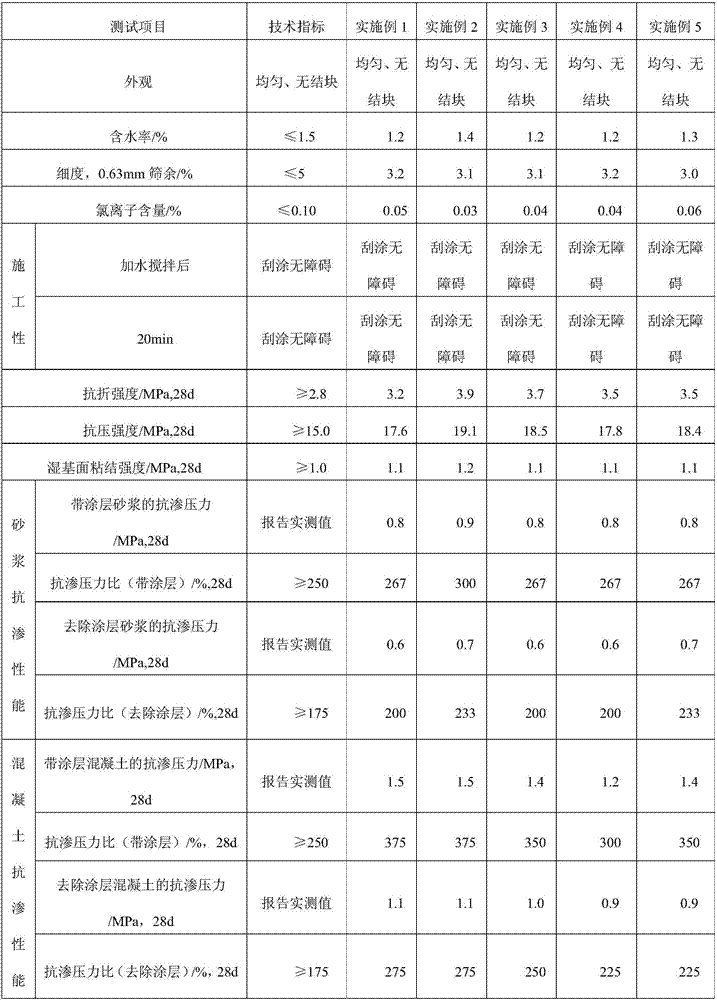

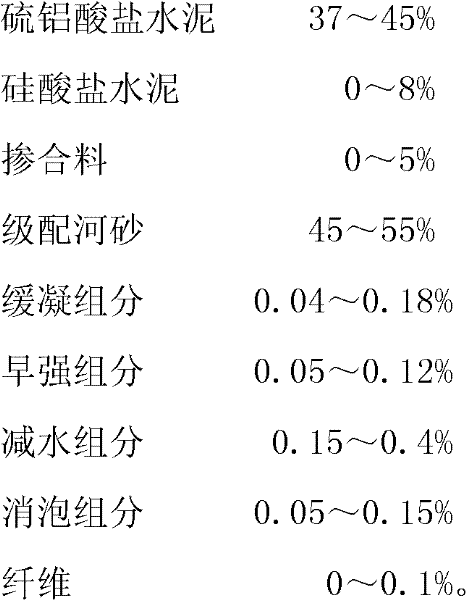

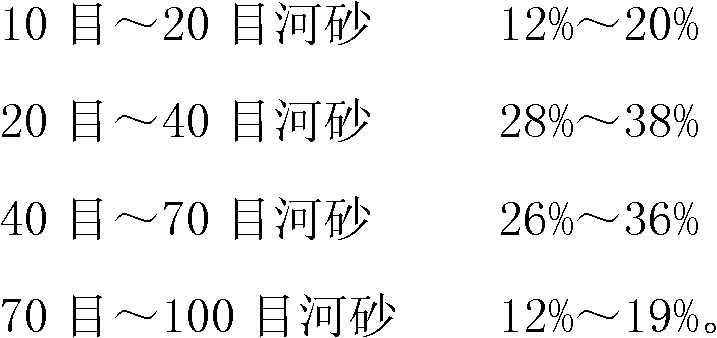

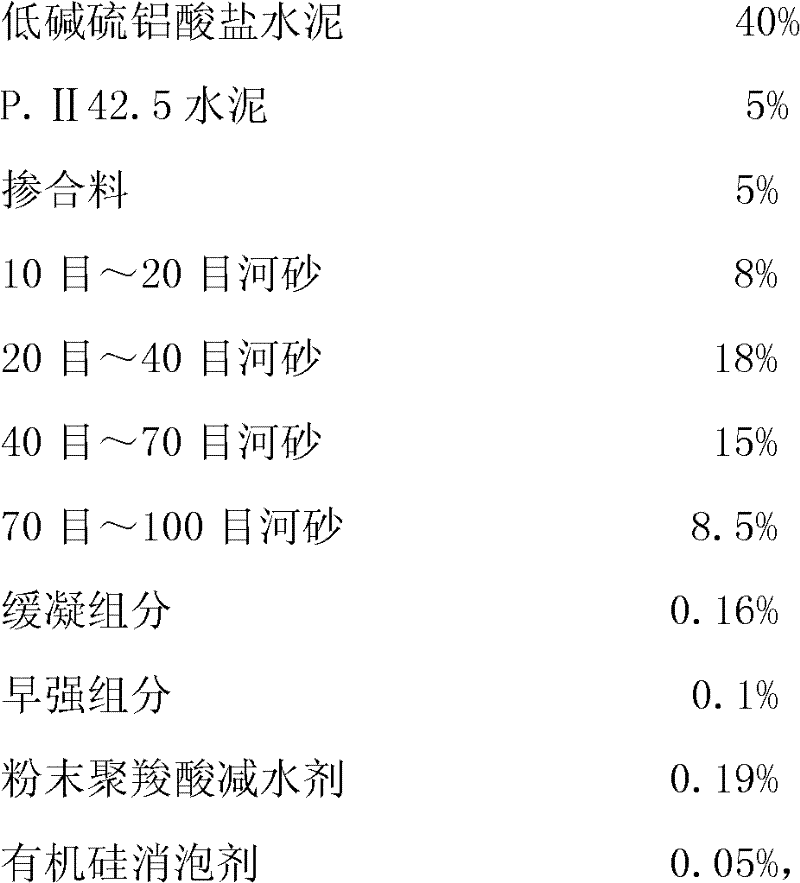

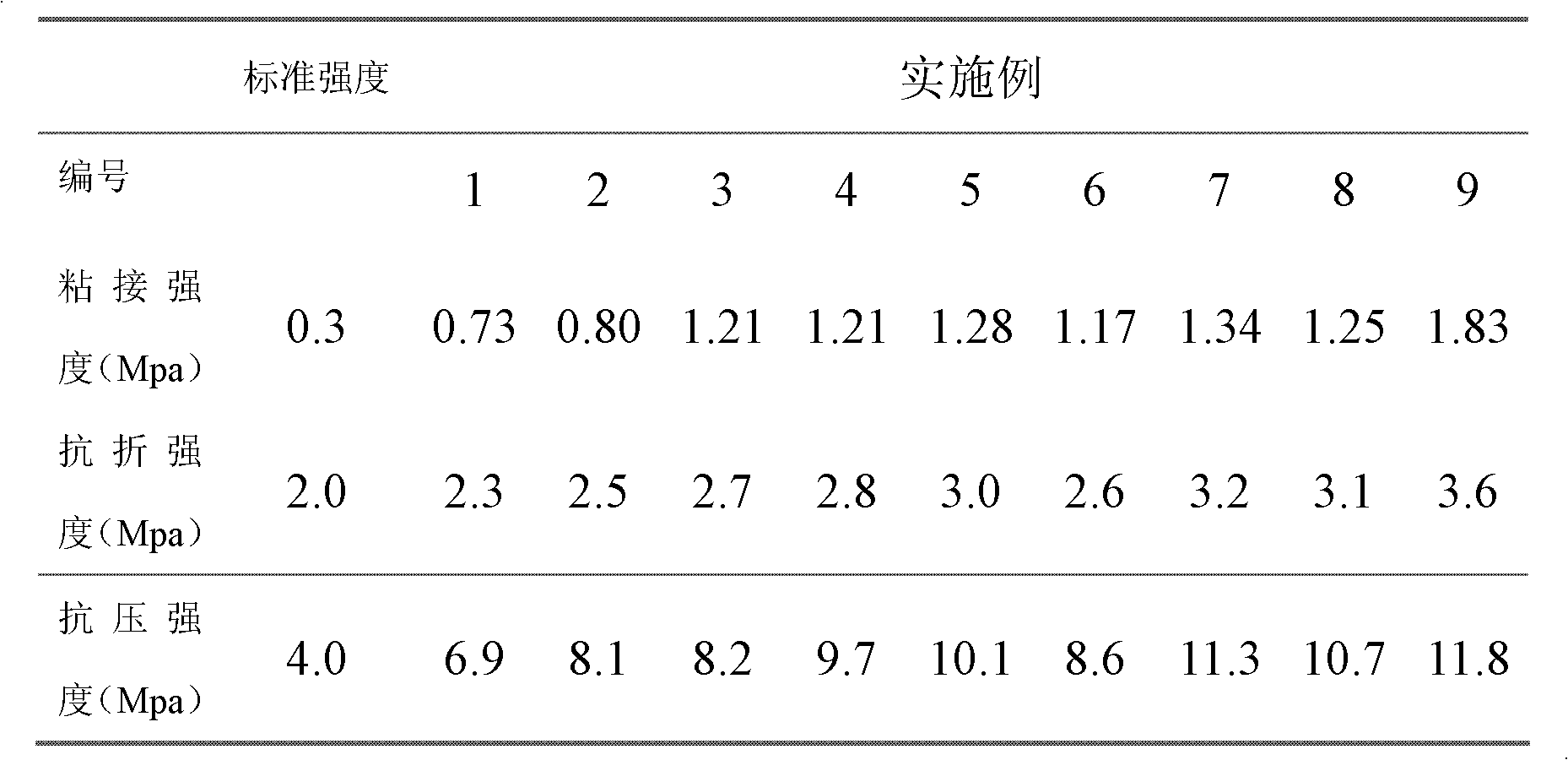

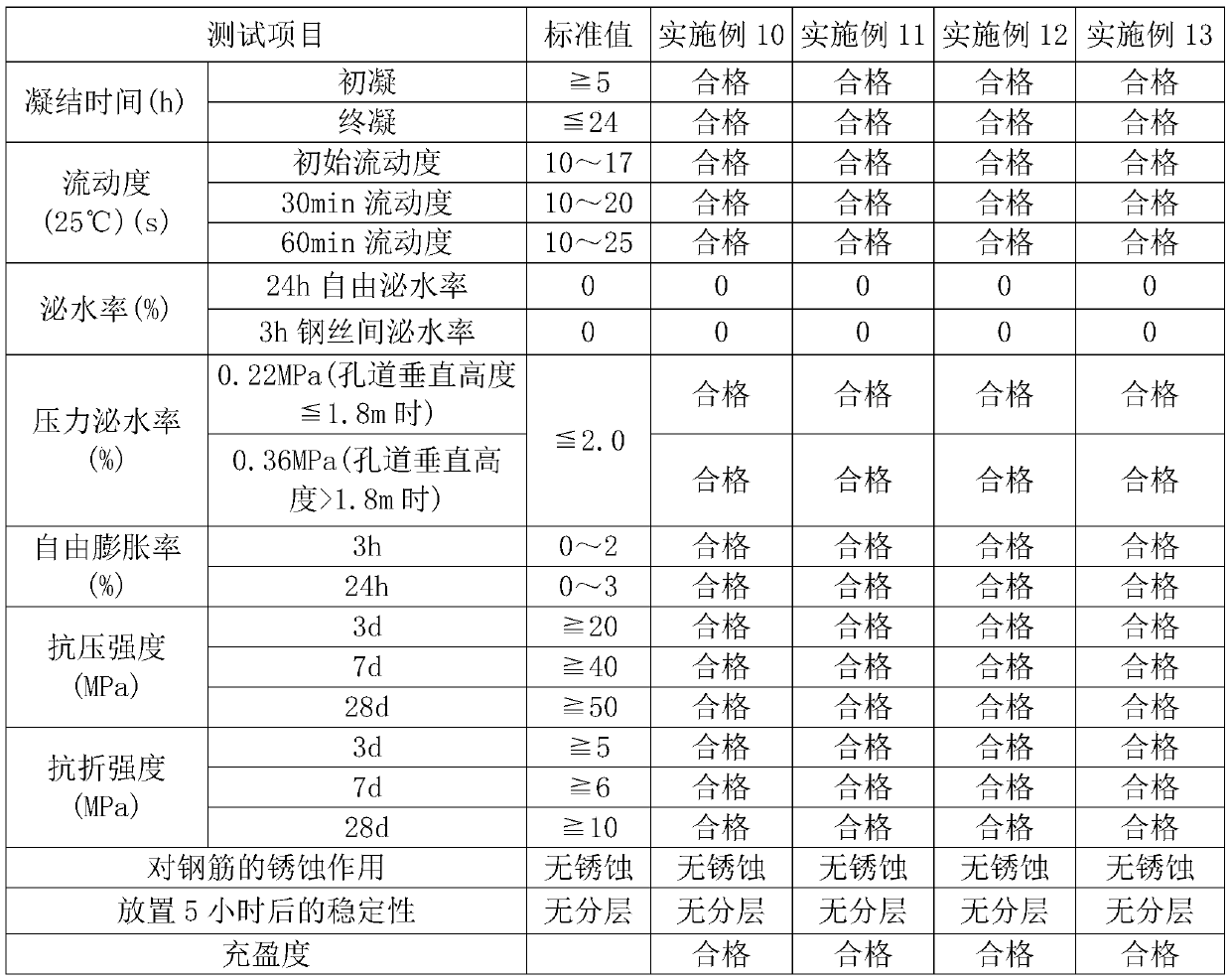

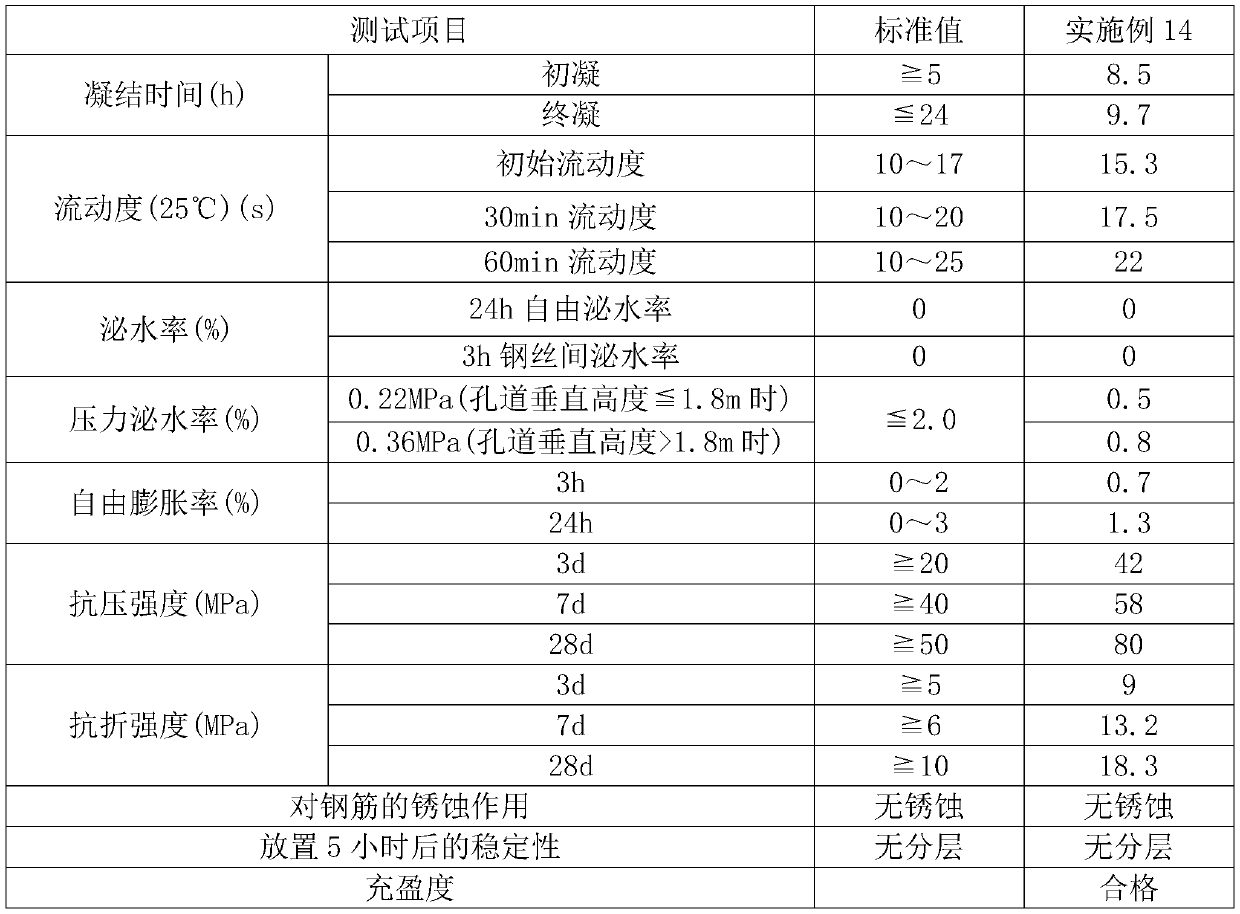

High speed railway bridge bearing anchoring mortar material

The invention discloses a high speed railway bridge bearing anchoring mortar material with is blended from components of, by weight: 37 to 45% of sulphoaluminate cement, 0 to 8% of Portland cement, 0 to 5% of an addition, 45 to 55% of graded river sand, 0.04 to 0.18% of a solidification retarder, 0.05 to 0.12% of an accelerant, 0.15 to 0.4% of a water reducing component, 0.05 to 0.15% of a defrothing component, and 0 to 0.1% of fiber. The material provided by the invention is specially used in anchoring and grouting of high speed railway bridge pot rubber bearings. The material has characteristics of good fluidity, high early strength, good filling properties, no strength reversing in later stage, low cost, convenient application, and the like. The material also can be applied in large equipment installation and pavement rush-repairing.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

Production process of novel multiple crystallization combined glass-ceramic clad plate

ActiveCN101177346ABreak luxuryBreak the contradiction of relatively simple color changeCeramic compositeBrick

The invention discloses a manufacturing technique of multiplex crystallization combination glass-ceramics ceramic composite panel. The invention is characterized in comprising following steps: (1) preparing transparent type non-crystallization high-strength frit, translucent half crystallization type and crystallization type crystal frit and non-transparent half crystallization type and crystallization type crystal frit, (2) making special mixture and mixing craft, (3) distributing the crystal frit onto the adobe; (4) performing roll forming and coating fixing agent, and (5) burning, cooling, polishing, edging and sorting and checking. The invention has the advantages of preparing porcelain tile, enabling organic combination of transparent, translucent and non-transparent colored crystals, simple technology, lower cost and diversified color similar to jade.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

Bottom layer brushing gypsum and application thereof

The invention discloses a bottom layer brushing gypsum, which is prepared by mixing the following components in parts by weight: 200-500 parts of building gypsum, 485-785 parts of quartz sand, 3 parts of regulator, 5 parts of inorganic gel, 0.2-0.5 part of retarder and 2 parts of anti-cracking agent, wherein the quartz sand is one or the mixture of more than two of the quartz sands of 30 meshes, 40 meshes and 60 meshes in any proportion, the regulator is hydroxypropyl methyl cellulose, the inorganic gel is sodium bentonite, the retarder is a special retarder for polyphosphate gypsum, and the anti-cracking agent is lignocellulose; and the building gypsum is prepared by desulfurized gypsum according to the following method that the desulfurized gypsum enters a boiling calcinator after being pre-dried at the temperature of 80-90 DEG C, is calcined at the temperature of 120-130 DEG C, then is added into an impact type flour mill to be ground, and is prepared into the building gypsum after being cooled and aged. The invention has strong adhesive force, effectively inhibits the phenomenon of shrinkage cracking in plastering, and has good water resistance.

Owner:上海每天节能环保科技股份有限公司

Fiber reinforced modified foam cement thermal insulation board and preparation process thereof

InactiveCN107226657ALow water absorptionHigh strengthHeat proofingCeramicwarePolymer scienceThermal insulation

The invention discloses a fiber reinforced modified foam cement thermal insulation board and a preparation process thereof. The fiber reinforced modified foam cement thermal insulation board uses a modified foam cement thermal insulation board as a thermal insulation core material, wherein alkali-resistant fiberglass cloth is attached to the upper surface and the lower surface of the modified foam cement thermal insulation board, polymer glue is applied onto the upper surface and the lower surface of the foam cement thermal insulation board through spray coating, roller coating, dip coating or scraping so as to integrate the alkali fiberglass cloth with the modified foam cement thermal insulation board to prepare a novel light cement-based inorganic thermal insulation board. The novel light cement-based inorganic thermal insulation board has the advantages of high strength, high toughness, low water absorption rate, low heat conduction coefficient, good thermal insulation effect, small drying shrinkage value, high adhesiveness, high integrity, good anti-vibration and anti-impact performance, A-level fire-proof performance, long service life as a building and the like. A used polycarboxylate superplasticizer modified graphene can disperse in cement paste uniformly and steadily, so that the problems of agglomeration, non-thorough disperse and the like in an existing graphene adding manner are solved.

Owner:CHONGQING CITY HUTH BUILDING MATERIALS LIMITED

Waterproof adhesive powder composition and its prepn process

The present invention is one kind of waterproof adhesive powder composition and its preparation process. The waterproof adhesive powder composition consists of aluminosilicate powder 30-40 wt%, hydrous siliate powder 15-35 wt%, silica powder 5-15 wt%, calcium carbonate powder 5-15 wt%, mineral powder 5-15 wt%, ethylene glue powder 5-15 wt%, plasticizer 0.5-1.5 wt%, thickener 0.2-0.5 wt%, organosilicon 1-3 wt%, coagulation accelerator 0.1-0.3 wt%, and anticracking agent 0.05-0.15 wt%.

Owner:苏笮斌

Preparation method of water-permeable ceramic brick

The invention discloses a preparation method of a water-permeable ceramic brick. The preparation method comprises the following steps: preparing of raw materials, dosing, mixing, forming, drying and sintering, wherein the raw materials are composed of the following components in parts by weight: 86-92 parts of ceramic tile waste ceramic particles, 5-12 parts of a high-temperature inorganic binder, 2-4 parts of water glass and 0.5-2 parts of a low-temperature organic binder, wherein the mass concentration of the water glass is 1.3-1.5 g / cm<3>. The preparation method can improve the strength of a green body in the sintering process and the utilization rate of the ceramic tile waste ceramic particles and reduce the cost of the binder; the prepared water-permeable ceramic brick has high compressive and bending strength.

Owner:辽宁法库陶瓷工程技术研究中心

Retarding-type cement grinding aid

InactiveCN106082761AImprove early and late strengthSpeed up the flowPolyaspartic acidCement grinding

The invention relates to the technical field of cement additives, particularly a retarding-type cement grinding aid. The retarding-type cement grinding aid is prepared from the following raw materials in parts by weight: 18-28 parts of triethanolamine, 12-24 parts of diethanolisopropanolamine, 2-8 parts of sodium tartrate, 5-17 parts of coco fatty acid diethanol amide, 8-16 parts of sodium gluconate, 6-14 parts of polyaspartic acid and 50-70 parts of water. The retarding-type cement grinding aid has favorable retarding effect, can enhance the early strength and later strength of cement, and is beneficial to enhancing the impermeability and freeze-thaw resistance of hardened concrete.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Alumina-titanium calcium aluminate-silicon carbide multiphase refractory material and preparation method thereof

The invention relates to an alumina-titanium calcium aluminate-silicon carbide multiphase refractory material and a preparation method thereof. According to a technical scheme in the invention, 40 to 45 wt% of special alumina particles, 20 to 30 wt% of fine special alumina powder, 10 to 20 wt% of titanium calcium aluminate particles, 4 to 9 wt% of silicon carbide particles, 4 to 9 wt% of fine silicon carbide powder, 1 to 2 wt% of elemental silicon, 2 to 5 wt% of fine powder of active alpha-Al2O3, 2 to 6 wt% of fine powder of white clay produced in Guangxi Province and 0.5 to 1.5 wt% of fine Y2O3 powder are used as raw materials, a binder accounting for 3 to 4 wt% of the raw materials is added, and mixing and milling are carried out so as to obtain a mixture; and then the mixture is subjected to ageing, mechanical pressing, demoulding, standing, drying, retention at 1400 to 1530 in an air atmosphere in a muffle furnace for 180 to 240 min, and cooling in the furnace successively so as to prepare the alumina-titanium calcium aluminate-silicon carbide multiphase refractory material. The preparation method provided by the invention is low in cost, simple in process and high in yield; and the prepared alumina-titanium calcium aluminate-silicon carbide multiphase refractory material has great volume density, great flexural and compression strength, low heat conduction coefficient and excellent thermal shock resistance.

Owner:WUHAN UNIV OF SCI & TECH

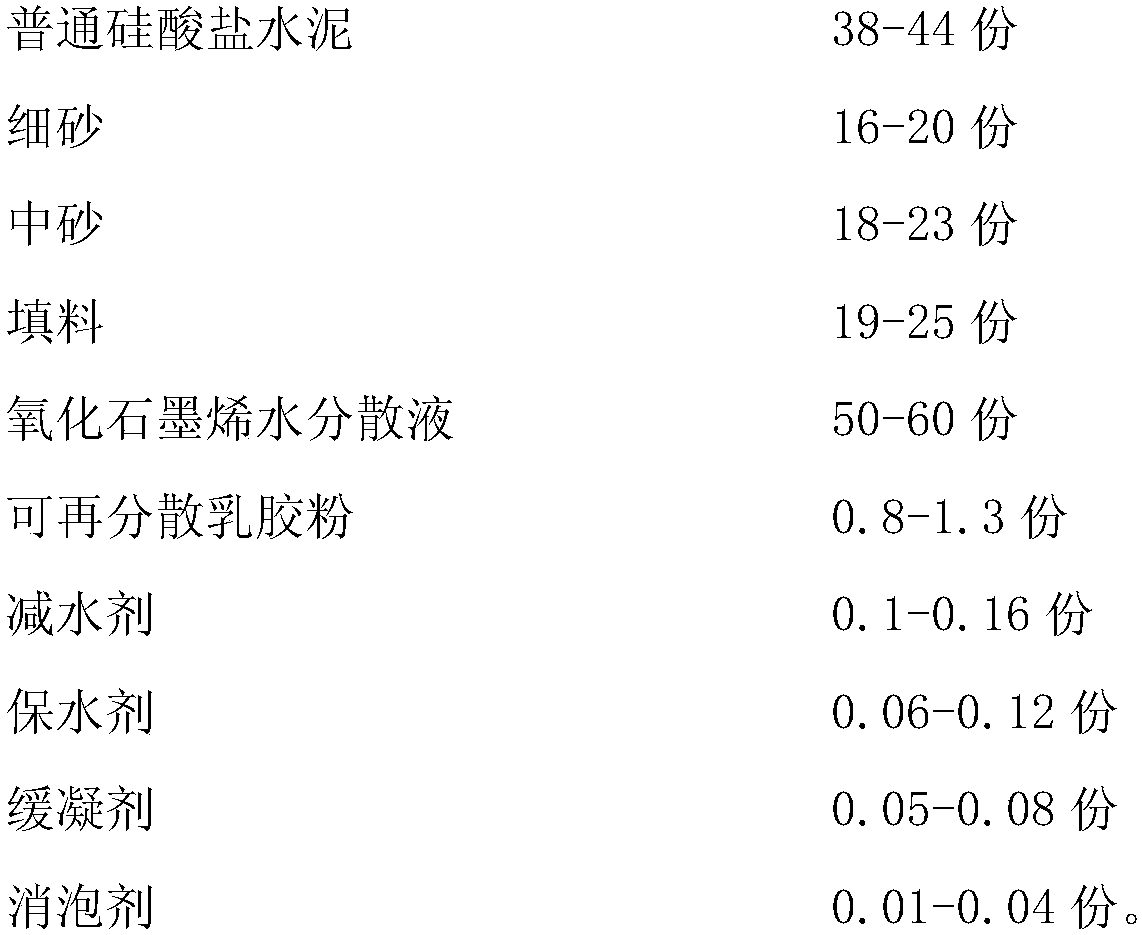

High-strength self-leveling mortar terrace material for surface layer and preparation method

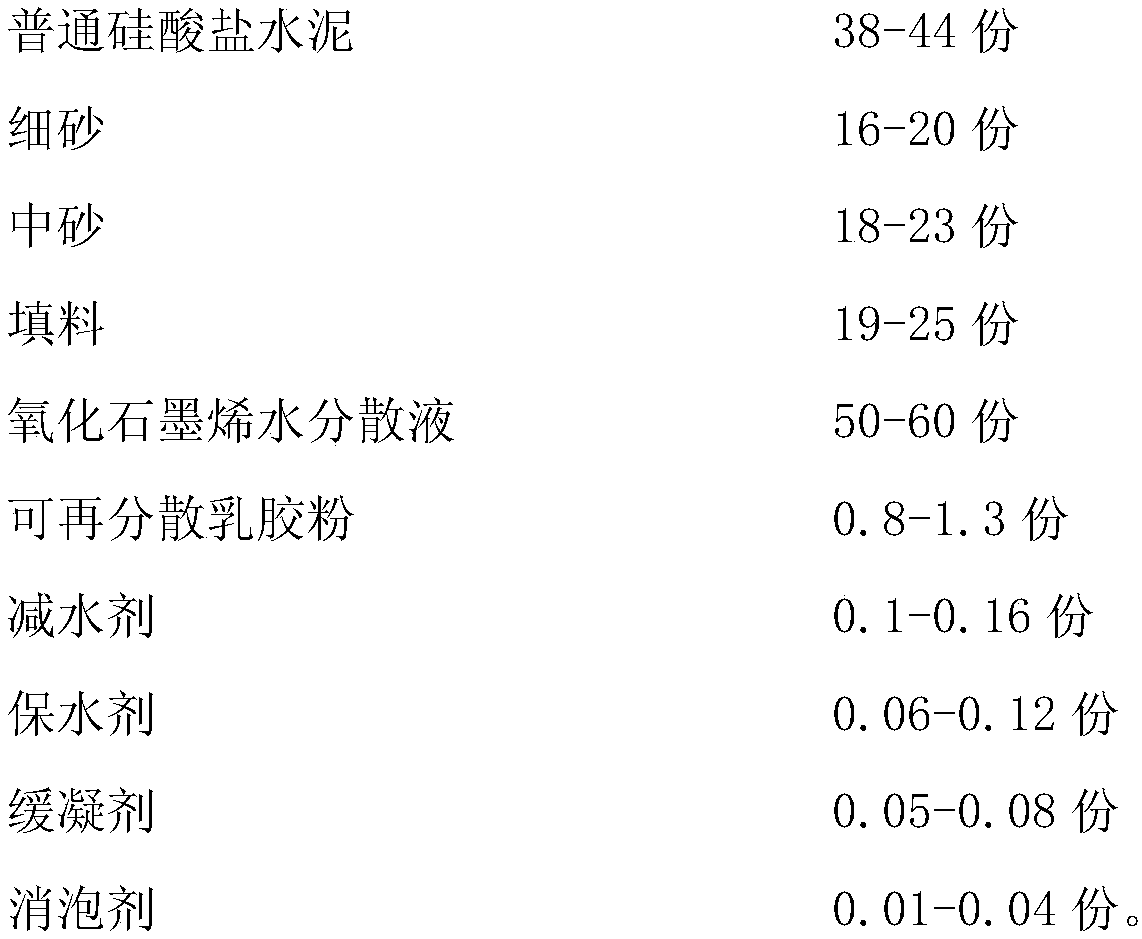

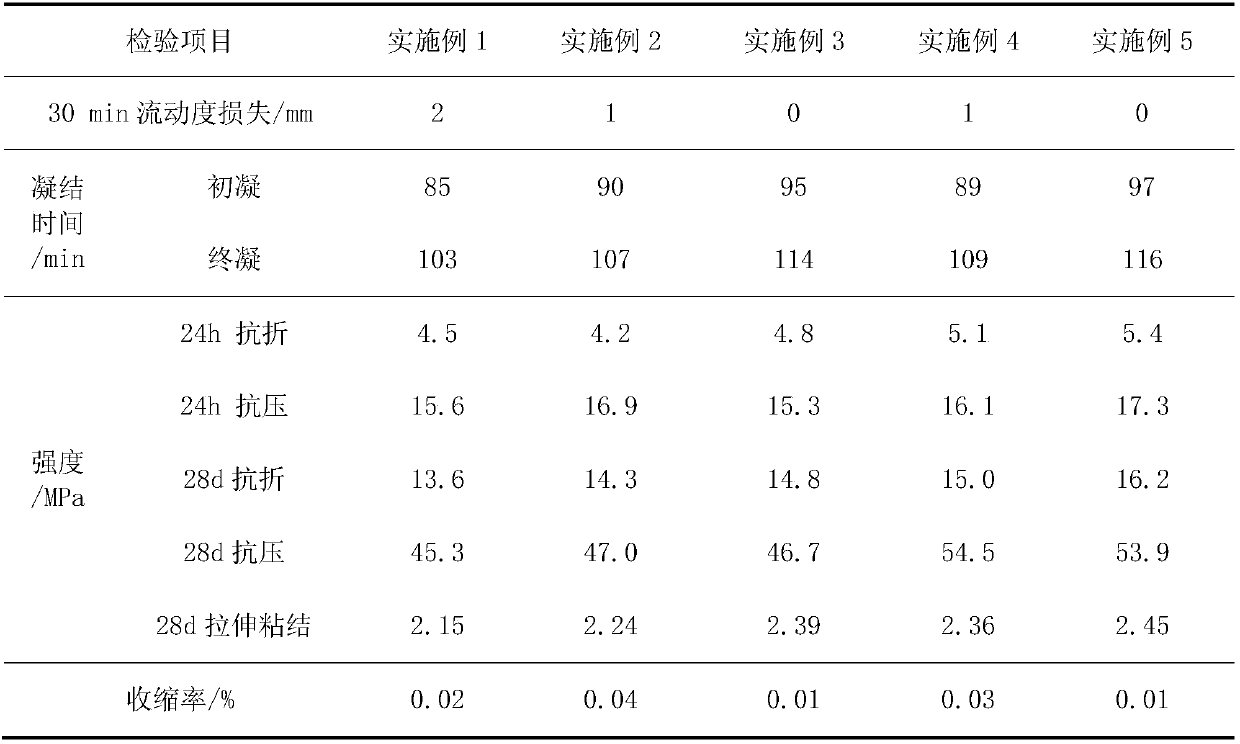

The invention discloses a high-strength self-leveling mortar terrace material for a surface layer, aiming at overcoming the disadvantages of a common self-leveling material that the mechanical strength is low and the common self-leveling material is easy to crack and pulverize. Meanwhile, graphene oxide has a regulation and control effect on a shape of a cement hydrated product and a toughening and reinforcing effect, so that the service life can be prolonged. The high-strength self-leveling mortar terrace material for the surface layer, disclosed by the invention, is prepared from the following components in parts by mass: 38 to 44 parts of ordinary portland cement, 16 to 20 parts of fine sand, 18 to 23 parts of medium sand, 19 to 25 parts of filling, 50 to 60 parts of a graphene oxide water dispersion solution, 0.8 to 1.3 parts of re-dispersible latex powder, 0.1 to 0.16 part of a water reducing agent, 0.06 to 0.12 part of a water-retaining agent, 0.05 to 0.08 part of a retarder and0.01 to 0.04 part of a de-foaming agent.

Owner:NANJING UNIV OF TECH

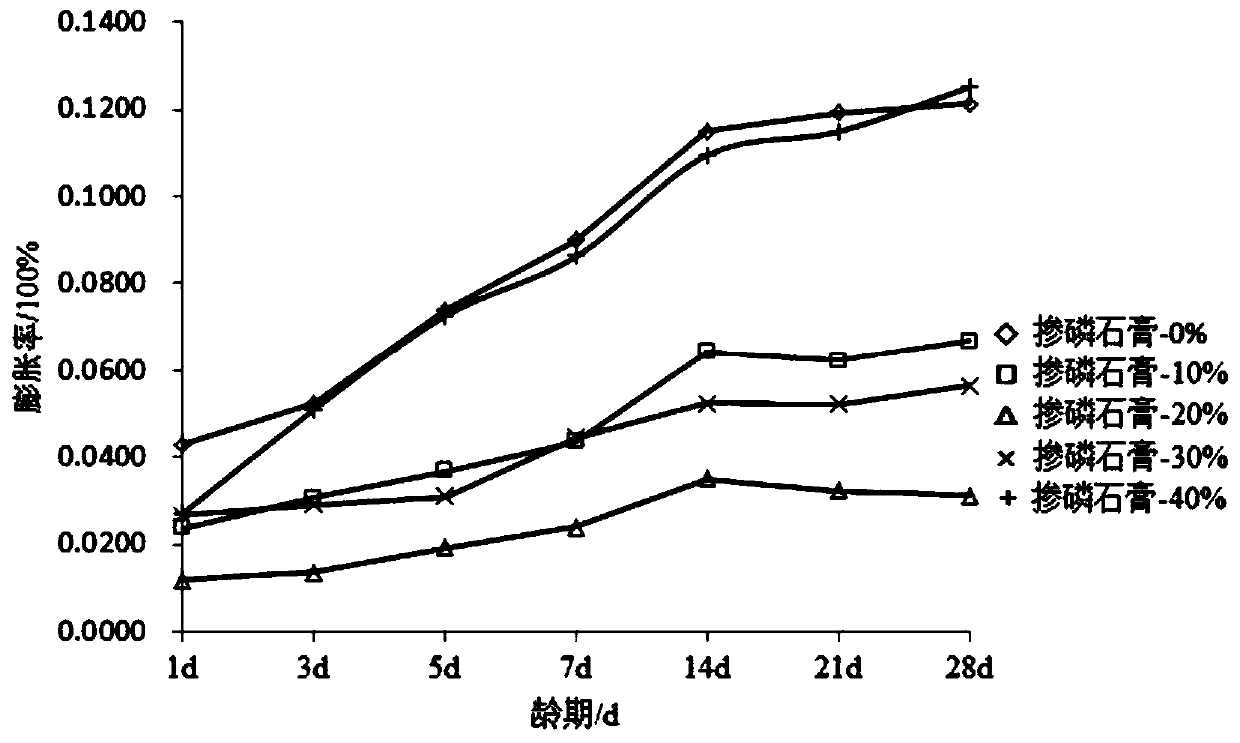

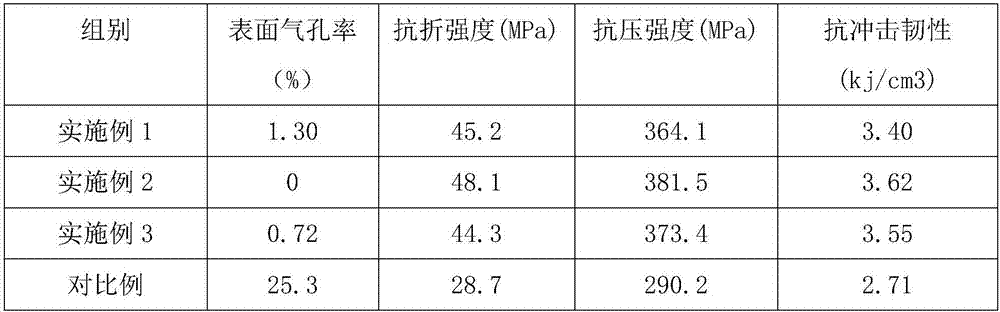

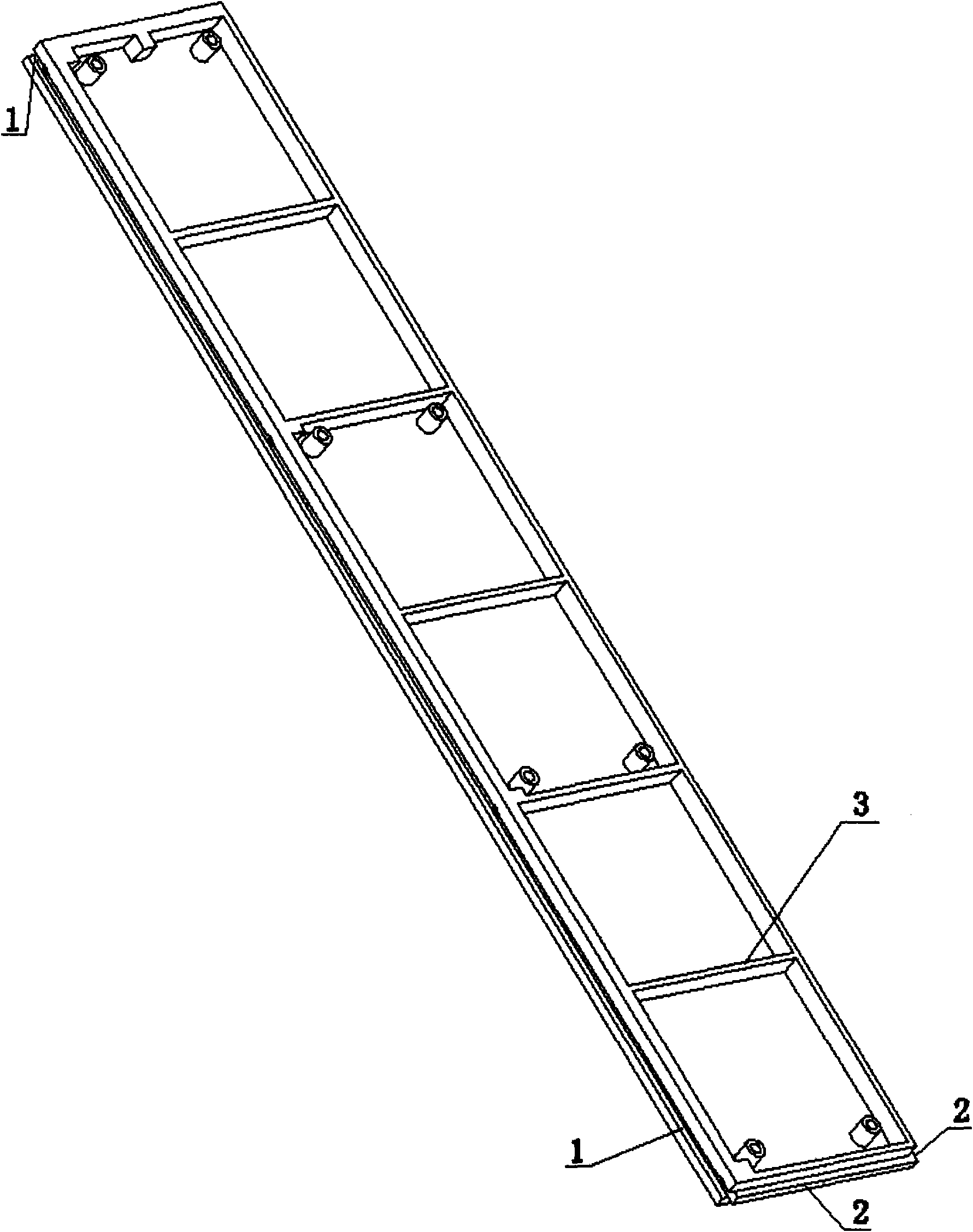

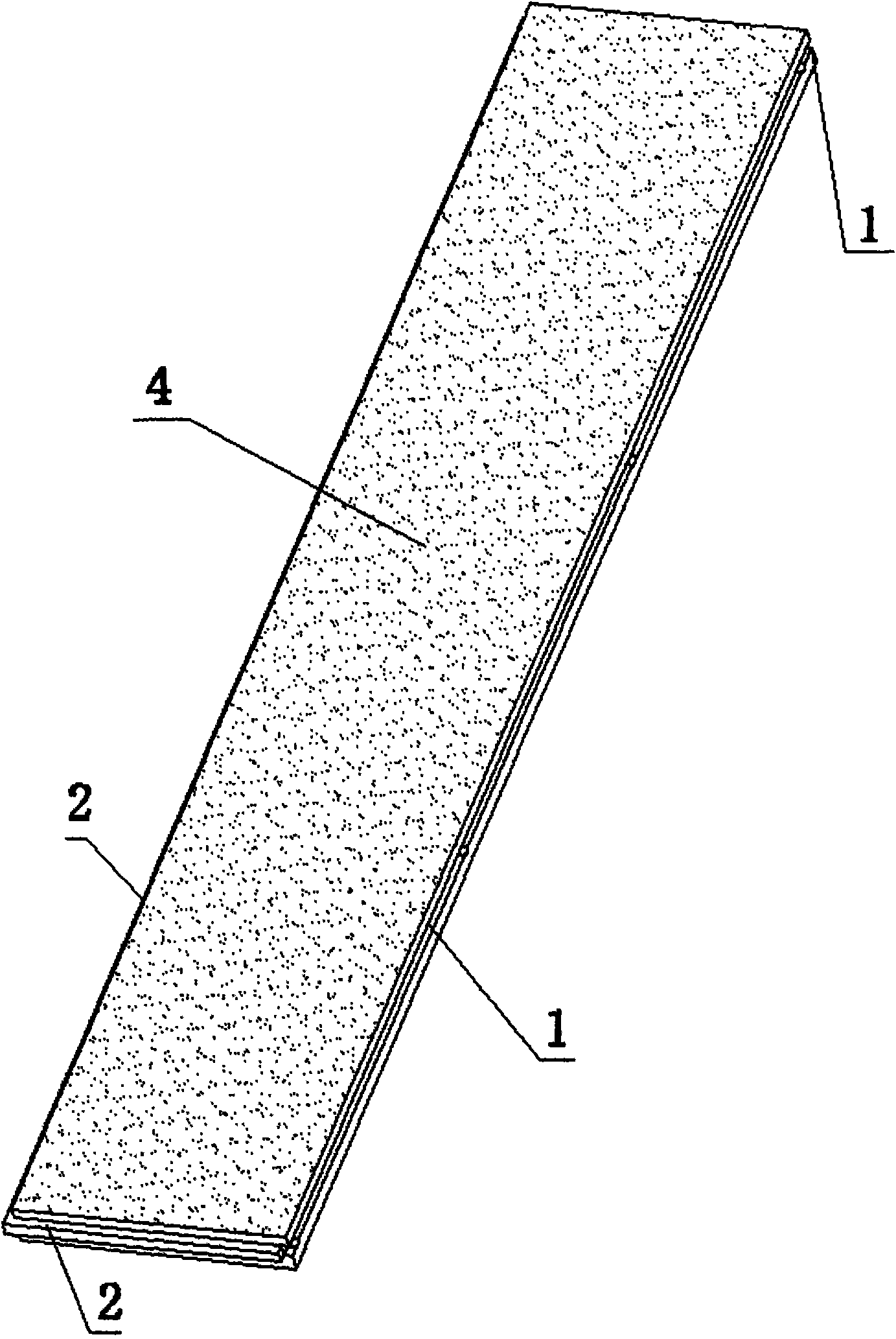

Phosphogypsum-doped quick-setting and quick-hardening cement matrix, concrete canvas prepared from cement matrix and construction method of concrete canvas

ActiveCN110577375AHigh strengthSolve the problem of accumulating and occupying land and polluting groundwater qualityFilm/foil adhesivesFibre typesFiberPhosphogypsum

The invention relates to a phosphogypsum-doped quick-setting and quick-hardening cement matrix, concrete canvas prepared from the cement matrix and a construction method of the concrete canvas. The raw materials of the cement matrix are composed of the following components in parts by weight: 700 to 800 parts of sulphoaluminate cement and 200 to 300 parts of acid-pickled phosphogypsum. A three-dimensional spacer fabric is filled with the phosphogypsum-doped quick-setting and quick-hardening cement matrix, and an adhesive sealing layer is arranged above the three-dimensional spacer fabric; thethree-dimensional spacer fabric comprises an upper woven fabric layer, a cellosilk layer and a lower woven fabric layer, and the cellosilk layer is composed of cellosilk distributed in a three-dimensional mode. The invention provides the novel cement matrix for the concrete canvas, the strength can be remarkably improved by doping phosphogypsum into the cement matrix system, so that excellent performance is obtained, and a feasible solving method can be provided for solving the current phosphogypsum problem by doping phosphogypsum.

Owner:CHINA THREE GORGES UNIV

Ardealite-based heat insulation mortar and preparation method thereof

ActiveCN108675743AImprove internal structural performanceRadioactive element reductionChemical industryO-Phosphoric Acid

The invention belongs to the technical field of environment protection and energy saving, in particular to ardealite-based heat insulation mortar. The ardealite-based heat insulation mortar is prepared from 12 to 20 parts of cement, 10 to 20 parts of ardealite, 80 to 120 parts of glass beads, 2 to 8 parts of quartz sand, 20 to 30 parts of water, 3 to 6 parts of quicklime and 1 to 2 parts of organic bonding agents in parts by weight. The raw materials use chemical gypsum produced through wet process phosphoric acid production as raw materials; the cost is effectively reduced; the comprehensiveutilization path of the ardealite waste can be widened; the consumption of solid waste in phosphorus chemical industry is increased; the sustainable development of the phosphorus chemical industry canbe promoted.

Owner:江苏腾跃建材有限公司

Drainage system pipe and manufacturing method thereof

InactiveCN101148337AHigh flexural and compressive strengthEasy to transport and installSewer pipelinesWeather resistancePolymer concrete

The present invention proposes one kind of pipe for drainage system and its production process. The polymer concrete pipe is produced with resin, sand and supplementary material. It may be used in trench, draining pipe, rhone and U-shaped drainage trough. It has the advantages of high strength, high corrosion resistance, high weather resistance, long service life, etc.

Owner:石家庄市银杏砂制品有限公司

Corrosion-resistant ceramic glass

InactiveCN107902910AHigh flexural and compressive strengthHigh mechanical strengthFiberPotassium silicate

The invention discloses corrosion-resistant ceramic glass, relating to the technical field of glass products. The ceramic glass is prepared from the following components: waste glass, micron-grade silicon dioxide, potassium silicate, mullite, boltonite, ceramic fiber, activated bauxite, andaluzite powder, magnesia-chrome spinel, and sodium fluorosilicate. Ceramic glass prepared by the prior art has the defects of different sizes of pores distributed unevenly and low water absorption. The prepared corrosion-resistant ceramic glass provided in the invention overcomes the above defects.

Owner:安徽凤阳亚欧玻璃工艺品有限公司

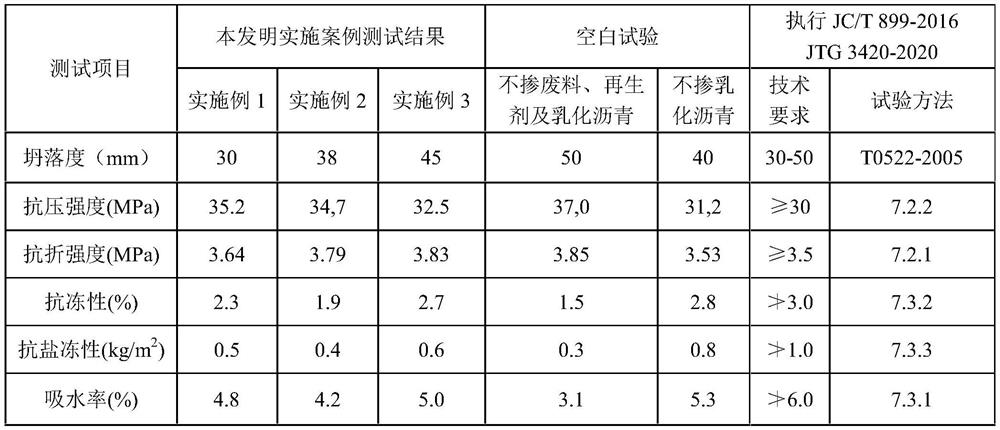

Recycled cement concrete prepared by recycling waste asphalt, and preparation method and application thereof

ActiveCN113816674AImprove compactnessSufficient flexural compressive strengthSolid waste managementPaving gutters/kerbsPlasticizerSuperplasticizer

The invention relates to a recycled cement concrete prepared by recycling waste asphalt, and a preparation method and application thereof. The recycled cement concrete comprises a component A, a component B, a component C, a component D and a component E. The component A is composed of a cementing material cement and a reinforcing and toughening material; the component B comprises coarse aggregate and fine aggregate for cement concrete; the component C is formed by mixing a waste asphalt mixture, a rapid regenerant, emulsified asphalt and water; the component D is a super plasticizer; the component E is a surfactant aqueous solution; and the recycled cement concrete comprises, by mass, 13 to 20 parts of the component A, 60 to 80 parts of the component B, 25 to 35 parts of the component C, 1.28 to 1.98 parts of the component D and 5 to 8 parts of the component E. The aged asphalt in the waste asphalt mixture can be rapidly regenerated, the non-tight bonding performance existing at the interface of the waste asphalt mixture and the cement is improved, the workability and the compression resistance and bending resistance of the regenerated cement concrete are improved, and the regenerated cement concrete can be nearby used for curbs, side slope protection building blocks and other engineering members, and has broad application prospects.

Owner:山西交通养护集团有限公司 +1

Perlite flame-retardant plate and preparing method of perlite flame-retardant plate

The invention discloses a perlite flame-retardant plate and a preparing method of the perlite flame-retardant plate. The perlite flame-retardant plate comprises a door leaf door core and auxiliary packing, wherein the auxiliary packing is placed in the door leaf door core and consists of the following ingredients in proportioning by weight: 10 to 20kg of expanded perlite, 26 to 39kg of magnesium chloride, 11 to 24kg of magnesium oxide, 200 to 300ml of phosphoric acid solutions with the concentration of 5 percent, 15 to 20kg of talcum powder, 0.1 to 2.0kg of emulsifying agents, 51 to 115kg of bonding agents, 4kg of a ferrous sulfate solution and 25 to 30kg of waterproof agents. The perlite flame-retardant plate has the advantages that flame-retardant and heat-insulation properties and non-toxicity are achieved; the flexural and compressive strength is high; aging is avoided; and the hydrophobicity under the high-humidity condition is high, so the perlite flame-retardant plate does not get damp.

Owner:台州市新龙甲防火门有限公司

Preparation method of microcrystal glass

InactiveCN107235635AEliminate size differencesHigh flexural and compressive strengthGlass rolling apparatusFlexural strengthMaterials science

The invention discloses a preparation method of microcrystal glass and relates to the technical field of glass products. The preparation method comprises the following steps: 1) weighing materials, namely broken glass, coal gangue, sanidine, anorthite, barium feldspar, natrolite, borax, titanium dioxide, sodium fluorosilicate, aluminum oxide, zinc oxide, lanthanum trioxide and a clarifying agent; 2) smelting and carrying out crystallization treatment on other raw materials except the clarifying agent, so that glass melt is obtained; 3) adding the clarifying agent into the glass melt, stirring, melting, and carrying out clarification treatment; 4) pouring the clarified glass melt into a preheated mould through a material channel, and carrying out compression moulding by virtue of a calendaring machine; and 5) conveying the moulded glass product into a heat treatment furnace with the mould together, and carrying out annealing treatment, so that the microcrystal glass is obtained. The microcrystal glass is simple to prepare, low in production cost, compact in structure and pore-free, has the characteristics of high flexural strength and compressive strength, good toughness and good machining properties and is long in service life and applicable to popularization and application.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

Hemihydrate gypsum base material imitation wood floor and preparation method thereof

The invention relates to the technical field of chemical building materials, in particular to a hemihydrate gypsum base material imitation wood floor and a preparation method thereof. By properly proportioning and designing raw materials such as hemihydrate gypsum, cement, a coagulation accelerator and the like, the quality of the hemihydrate gypsum is improved, the activity of the hemihydrate gypsum is improved, the toughness and plasticity of a product made from the hemihydrate gypsum are improved, the flexural and compressive strength of a base material made from the hemihydrate gypsum as a raw material is enhanced, the freeze-thaw resistance of a phosphogypsum product is improved, and the weather resistance and corrosion resistance of the phosphogypsum product are improved; by combination with control on technical parameters in a preparation process after the raw materials are properly proportioned, the compatibility of the hemihydrate gypsum, the cement, the coagulation accelerator, fibers and the like is relatively good, holes of the product are uniform in size, and the waterproof and dampproof performance and mechanical strength of the hemihydrate gypsum base material are improved.

Owner:GUIZHOU KAILIN PHOSPHOGYPSUM INTEGRATION UTILIZATION

ABS plastic floor board

InactiveCN101608499AReduce weightHigh flexural and compressive strengthFlooringPlastic injection moldingAcrylonitrile

The invention discloses an ABS plastic floor board, which is prepared by ABS plastic injection molding technology. ABS plastic is a terpolymer prepared from the following raw materials in percentage by weight: 5 to 30 portions of acrylonitrile, 10 to 30 portions of butadiene and 40 to 70 portions of styrene. The surface of the ABS plastic floor board forms a square or rectangular shape, while the upper surface is provided with antiskid skin lines, the edge is provided with convex and concave interfaces, and the lower surface is provided with a plurality of strip strengthening ribs. The ABS plastic floor board has the advantages of corrosion resistance, moisture resistance, high temperature resistance, wear resistance, inconductivity, easy cleaning, environment protection, no toxicity, no odor and the like.

Owner:SHANGHAI JIASHENG IND CO LTD

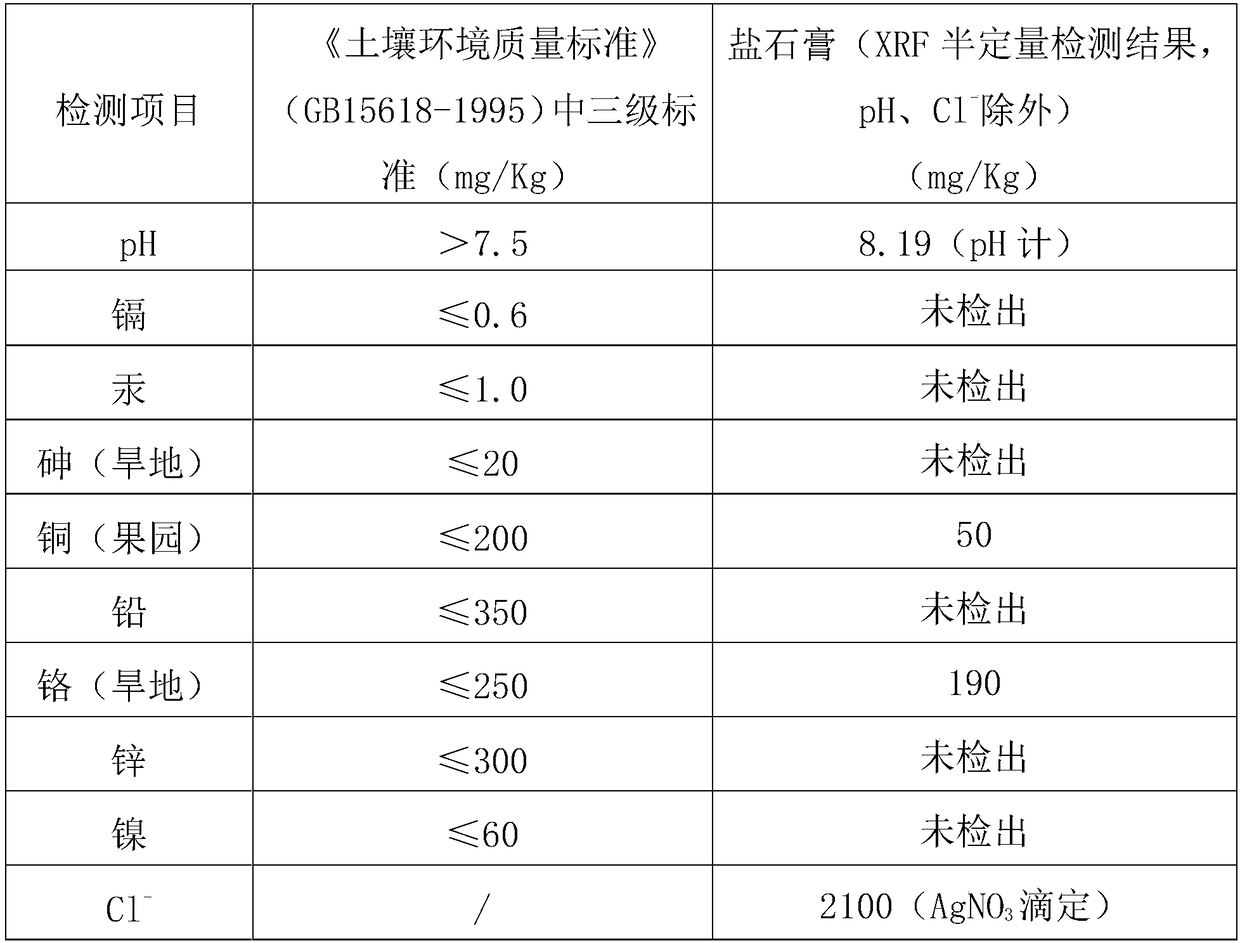

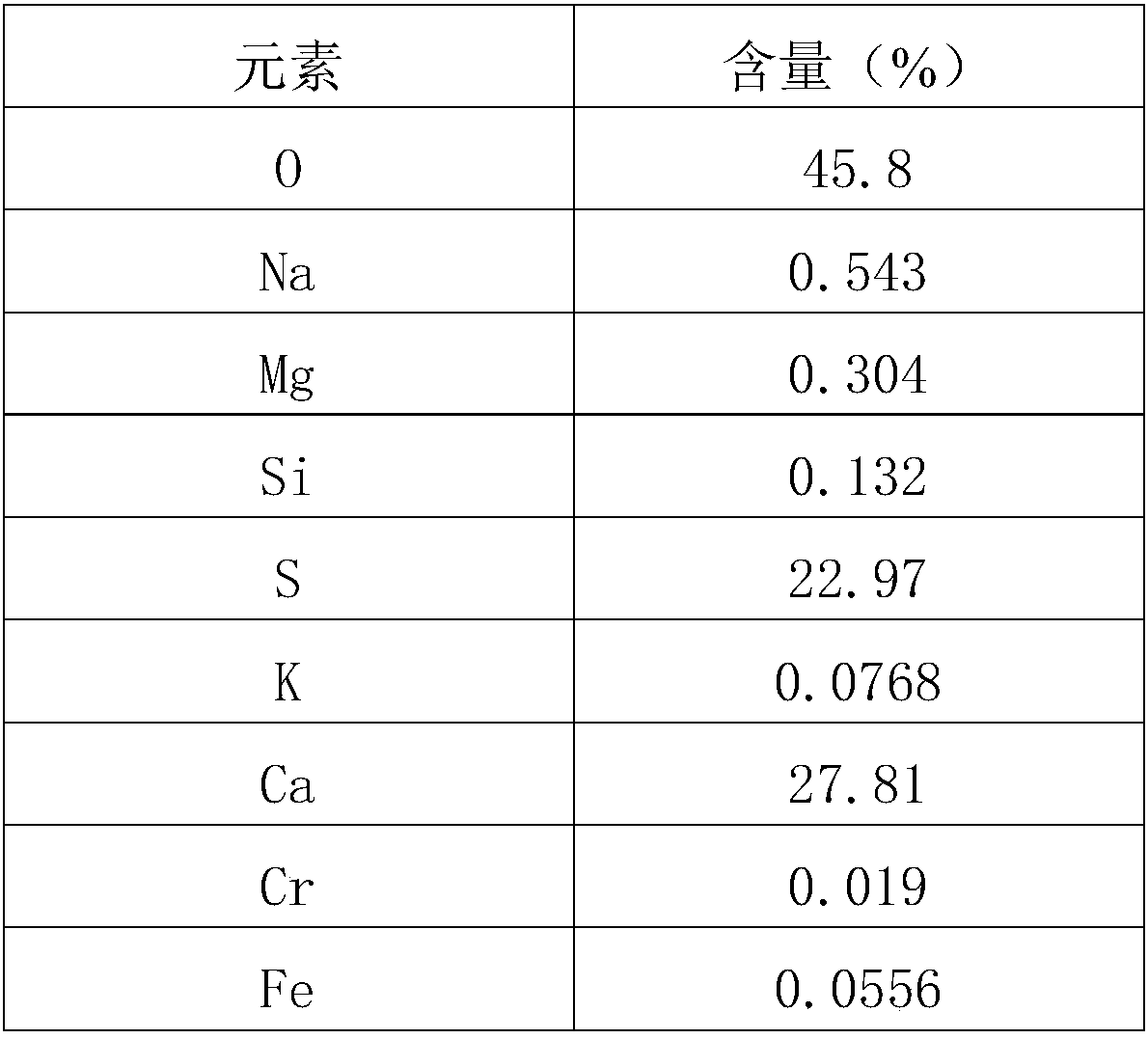

Expansion backfill prepared from salt gypsum as raw material and preparation method of expansion backfill

InactiveCN109437800AHigh flexural and compressive strengthHigh compressive strengthCeramicwareEcological environmentFoaming agent

The invention discloses an expansion backfill prepared from salt gypsum as a raw material. The expansion backfill prepared from the salt gypsum as the raw material comprises the following components:salt gypsum, an excitant, a foaming gent and water. The salt gypsum is transformed into dihydrate gypsum by the excitant, and the addition amount of the excitant is 2-12% of the weight of the salt gypsum; the addition amount of the foaming agent is 0.1-0.8% of the weight of the salt gypsum; and the addition amount of the water is 30-60% of the weight of the salt gypsum. The expansion backfill prepared from the salt gypsum as the raw material provided by the invention has the characteristics of being high in compressive strength, high in bonding strength, stable in size and the like, and phenomena such as sink and deformation are avoided after backfill; and meanwhile, the salt gypsum serves as the base material, high value-added comprehensive utilization of the salt gypsum is realized, theproblem that the land is destroyed when soil is extracted is solved, and the ecological environment is protected. Based on the expansion backfill, the invention further provides a preparation method of the expansion backfill prepared from the salt gypsum as the raw material.

Owner:湖南昌迅科技环保股份有限公司

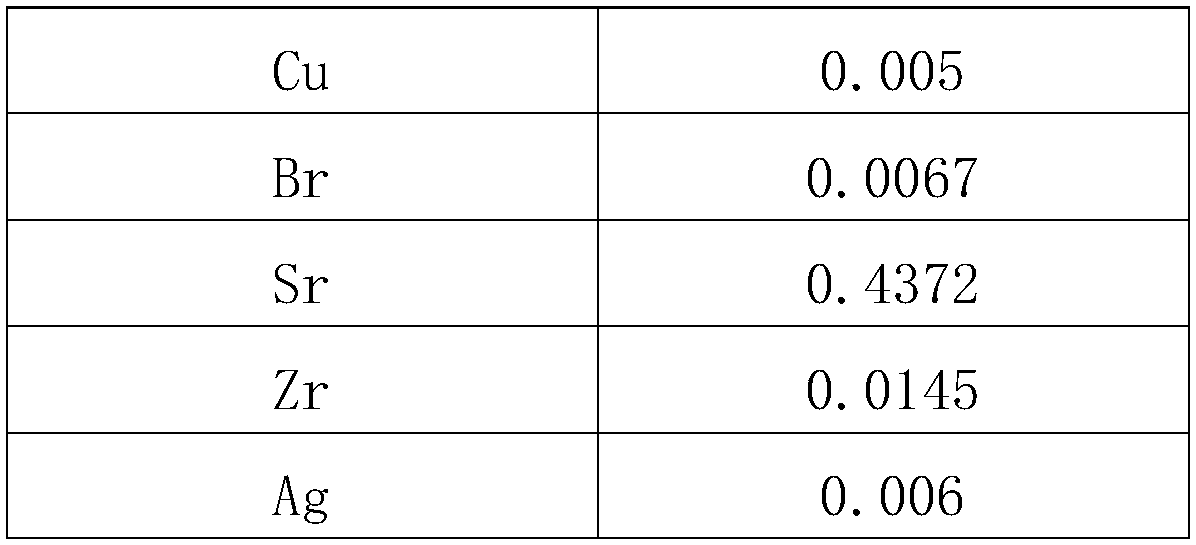

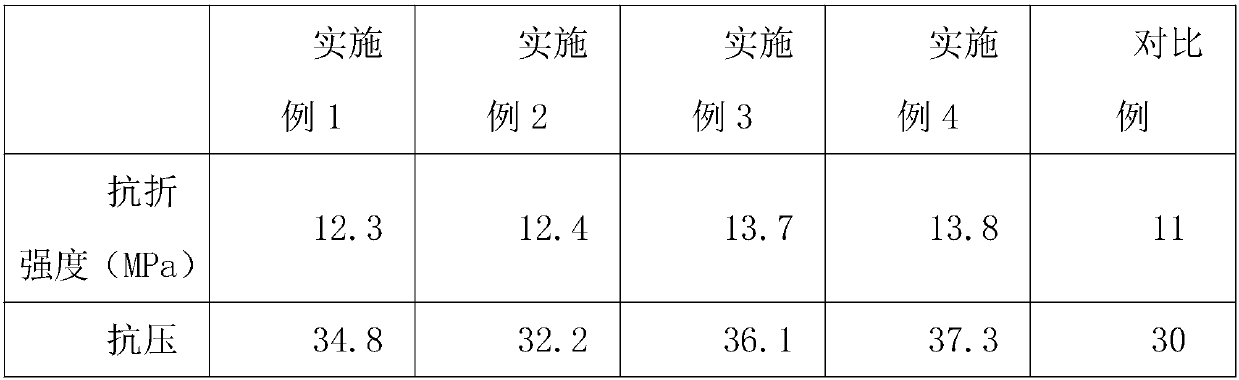

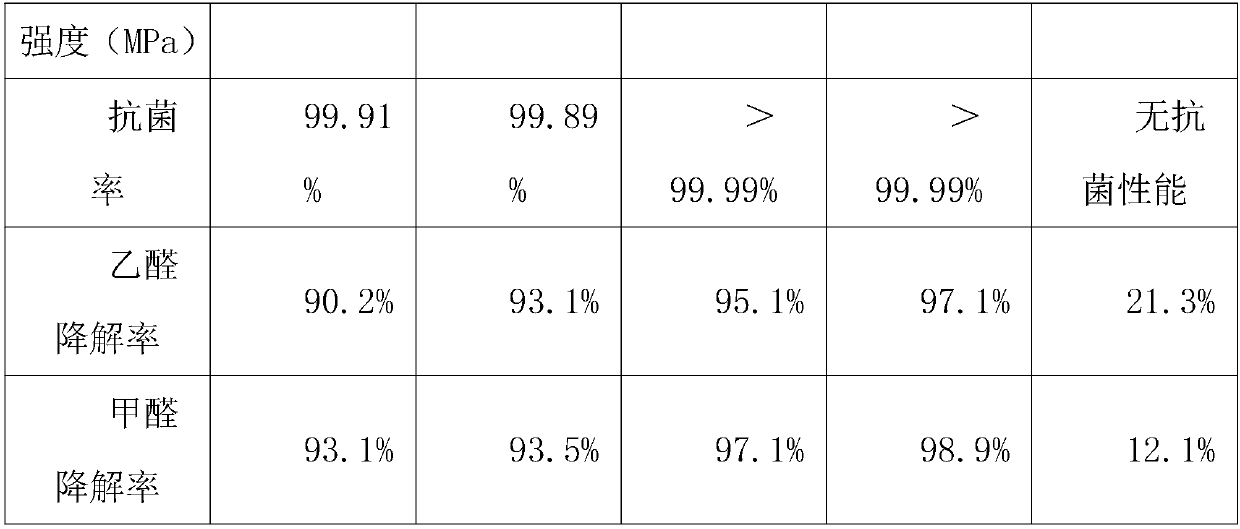

Prestress pipeline grouting agent, preparation method and grouting material

InactiveCN109704615AHigh flexural and compressive strengthReduce dosageDefoaming AgentsWater reducer

The invention relates to the technical field of grouting agent preparation, and particularly relates to a prestress pipeline grouting agent, a preparation method and a grouting material. The prestresspipeline grouting agent comprises the following components in parts by weight: 35-43 parts of mountain flour, 8-12 parts of a water reducer, 8-12 parts of a plastic expanding agent, 8-12 parts of a defoaming agent, 8-12 parts of silicon powder and 8-15 parts of quartz sand. Tests show that the grouting agent prepared by adopting the formula can be well compatible with various kinds of cement, theprepared grouting agent is more stable and balanced, and breaking strength and compressive strength at a later stage are both higher. Through the adoption of the formula, the content of the water reducer is reduced compared with the content of a water reducer in the prior art. The water reducer is an organic substance and can easily cause pollution in a production process, so that greenness and environment friendliness are achieved through the reduction of the usage amount of the water reducer.

Owner:深圳市红威达建材有限公司

Permeable brick with high performance

The invention discloses a permeable brick with high performance. A formula of the permeable brick comprises the following components in parts by mass: 10-15 parts of ceramic tile waste ceramic chip particles, 4-8 parts of titanium carbide, 10-15 parts of aluminum oxide, 10-15 parts of organic silicone resin, 13-15 parts of polyurethane resin, 7-10 parts of nanometer titanium dioxide, 20-30 parts of absolute ethyl alcohol, and 3-5 parts of a dispersing agent. The characteristic that organic silicone resin is converted into silica is used in order to solve the problem that micropore structures in the sintering process are easy to collapse, strength of permeable bricks is substantially improved, and density of the permeable brick is reduced.

Owner:苏州米颜生物科技有限公司

High-strength environment-friendly light-transmission cement mortar and preparation method thereof

ActiveCN106242444AGood light transmissionHigh flexural and compressive strengthSodium acetateCrack resistance

The invention discloses high-strength environment-friendly light-transmission cement mortar composed of a cement-based grouting material and optical fibers, wherein the cement-based grouting material comprises the following components in parts by weight: 30-50 parts of aluminum sulfate salt cement, 60-80 parts of natural sand, 10-20 parts of a mineral powder, 5-7 parts of metakaolin, 3-6 parts of a medical stone powder, 2-3 parts of nitrogen doped titanium dioxide, 0.8-1.2 parts of calcium nitrate, 1-1.5 parts of sodium acetate, 2-3 parts of an inner curing agent, 1-2 parts of a water reducing agent, 1-2 parts of a defoaming agent, and 40-60 parts of water; the optical fibers are PMMA plastic lighting optical fibers with the diameter of 0.5 mm, the surface is coated with a polytetrafluoroethylene film, and the distance between the optical fibers is 3-4 mm. The prepared light-transmission cement mortar has the advantages of good light transmission performance, high flexural and compressive strength, large toughness, and excellent crack resistance; and the preparation method is simple, has no toxic substance released in the preparation process, and is economic and environmentally friendly.

Owner:朔州金圆水泥有限公司

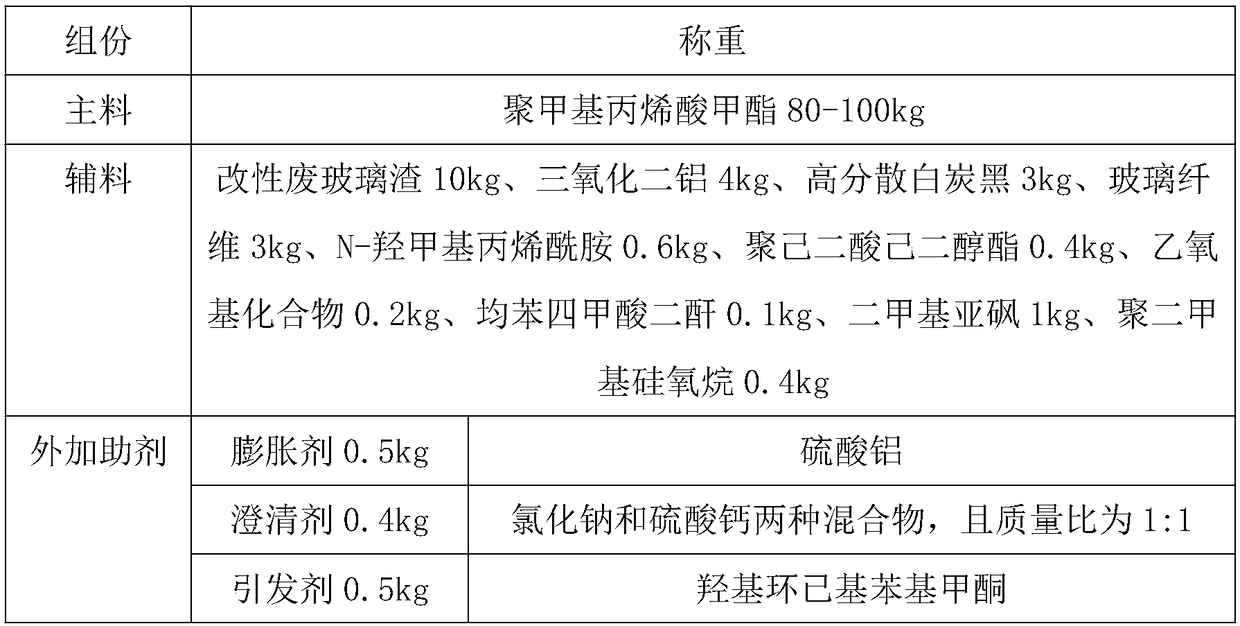

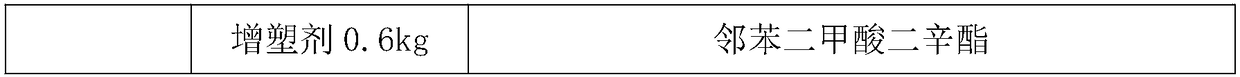

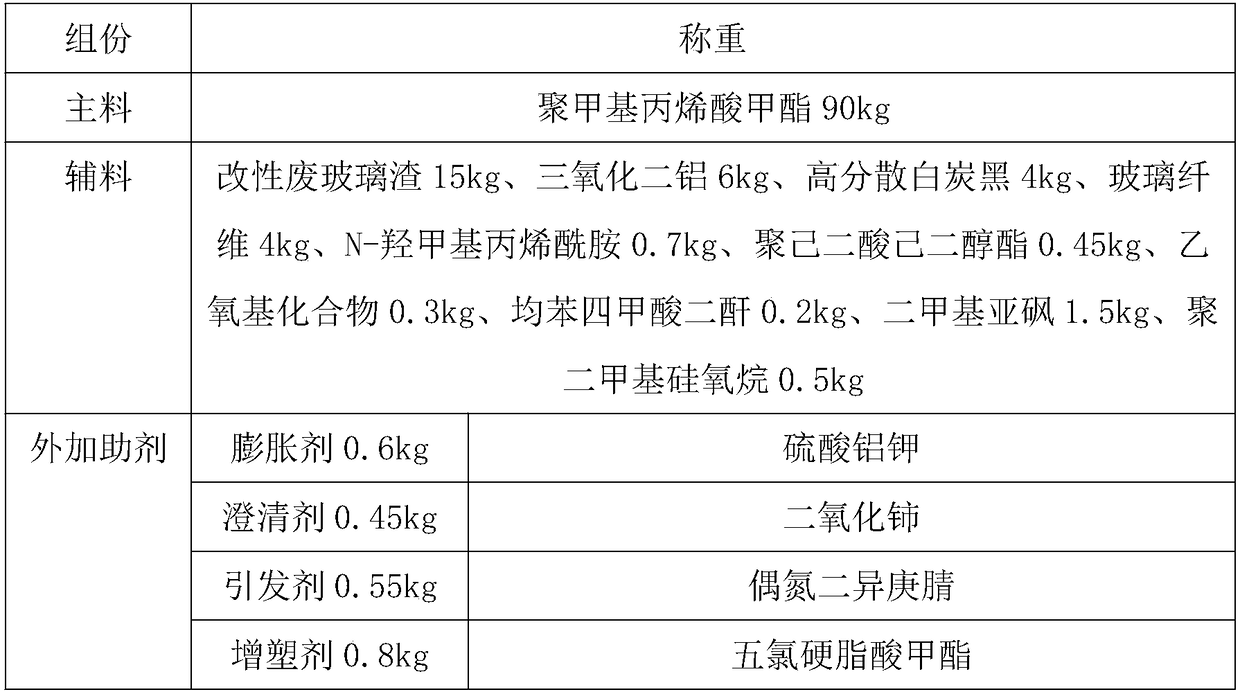

Organic glass material and preparation method thereof

Relating to the field of organic glass materials, the invention discloses an organic glass material and a preparation method thereof. The material comprises the following raw materials: polymethyl methacrylate, modified waste glass slag, aluminum oxide, highly dispersed white carbon black, glass fiber, N-hydroxymethyl acrylamide, polyhexanediol adipate, an ethoxylated compound, pyromellitic dianhydride, dimethyl sulfoxide, polydimethylsiloxane, an expansion agent, a clarifying agent, an initiating agent and a plasticizer. The preparation method includes: raw material mixing, heating and reaction. The organic glass material provided by the invention is simple and convenient to prepare, and has the characteristics of high flexural and compressive strength, good impact toughness, good machining properties, high temperature resistance and chemical reagent corrosion resistance, greatly widens the application fields of the organic glass material, prolongs the service life of organic glass products and improves the practicability of organic glass products, and has broad market prospects.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

Artware and fabrication method thereof

InactiveCN103274664AHigh flexural and compressive strengthThe production method is environmentally friendlyFiberPhosphate

The invention discloses artware which comprises the following raw materials in percentage by weight: 27-32% of magnesium oxide, 25-30% of magnesium chloride, 8-12% of plant fibers, 15-30% of packing, 6-8% of an additive, 2-4% of a diffusant NNO and the balance of water, wherein the packing is one, two or three of quartz sand, glass beads and fly ash; and the additive is one or two of polyvinylidene chloride latex and phosphate. The fabrication method comprises the steps of dissolving magnesium chloride in water, adding the rest raw materials in a solution, stirring uniformly in a stirrer to obtain slurry, pouring the slurry into a mold, then placing in a vacuum machine, exhausting air from the slurry, taking the mold out of the vacuum machine, placing for 3-5h, forming and demolding, placing the artware in a constant temperature humidity chamber for 72h, taking out the artware for natural drying, and trimming and coloring the artware. The artware is high in rupture strength and compressive strength, and resists low temperature, and the fabrication method is simple, environment-friendly and low in cost.

Owner:CHANGSHA INTAI BUILDING MATERIAL

Manufacturing method of light building board

The invention discloses a manufacturing method of a light building board. The manufacturing method comprises the following steps: adding a balanced amount of starch expanded material in foamed rapid hardening cement mixed slurry to be stirred uniformly, injecting the rapid hardening cement mixed slurry containing the starch expanded material into a forming mould for hardening forming. Since the hardening time of the rapid hardening cement is short, and the starch expanded material has certain water resistance, during the cement hardening process, the rapid hardening cement has been prehardened before the starch expanded material scatters and is dissolved, but the interior of the rapid hardening cement has no flowability, and the starch expanded material can be poured into a foamed space to reduce the volume weight of the product to enable the product to be lighter. Meanwhile, during the process of foamed magnesium cement hardening, most of the starch expanded material forms starch glue through micro-grinding and high-temperature gelatinization, and the starch expanded material is diffused toward the surrounding space in a starch glue form at the later period of hardening, so that the flexural and compressive strength of the product is improved greatly.

Owner:王铁石

High-strength cement-based self-leveling mortar prepared by desulfurization calcium plaster and preparation method thereof

InactiveCN110342890AFast setting and hardeningHigh flexural and compressive strengthAluminiumSilicate Cement

The invention discloses a high-strength cement-based self-leveling mortar prepared by desulfurization calcium plaster, and belongs to the technical field of self-leveling mortar. The high-strength cement-based self-leveling mortar prepared by desulfurization calcium plasteris prepared from the following raw materials in parts by weight: 18 to 28 parts of desulfurized calcium plaster, 30 to 37 parts of aluminate cement, 5 to 6 parts of Portland cement, 35 to 39 parts of natural siliceous sand, 0.7 to 0.8 part of water reducing agent, and 0.01 part of thickener. The invention further discloses apreparation method of thehigh-strength cement-based self-leveling mortar prepared by the desulfurization calcium plaster. According to the high-strength cement-based self-leveling mortar prepared bythe desulfurization calcium plaster and the preparation method thereof, the performance characteristics of the desulfurized calcium plaster, high-alumina cement, and the ordinary Portland cement are fully utilized respectively, the prepared cement-based self-leveling mortar has the characteristics that the setting and hardening speeds are fast, fracture resistance and crush resistanceof early andlater periods are high, wear resistance is good,the surface is not prone to being pulverized, and impact performance is good; the plasterin the desulfurized calcium plaster is not subjected to treating processes such as pressure filtration and drying, so that the dispersion effect of the desulfurized plasterin cement slurry is better, the production cost is lowered, new approaches are provided forpreparation of cement-based self-leveling mortar and resource utilization of desulfurizedcalcium plaster,and economic and environmental benefits are good.

Owner:YANCHENG INST OF TECH

Multifunctional wear-resistant fireproof adhesive and production method thereof

InactiveCN107254260AHigh flexural and compressive strengthLong repair timeNon-macromolecular adhesive additivesInorganic adhesivesChemistryAdhesive

The invention discloses multifunctional wear-resistant fireproof adhesive and a production method thereof and belongs to the technical field of irregular fireproof castables. The multifunctional wear-resistant fireproof adhesive and the production method thereof according to the technical scheme are characterized in that the multifunctional wear-resistant fireproof adhesive is prepared from, by weight, 35-45 parts of phosphoric acid solution having a mass concentration of 85%, 15-25 parts of sulfuric acid solution having a mass concentration of 50%, 3-5 parts of alumina micropowder, 20-30 parts of corundum micropowder, 30-50 parts of high-aluminum micropowder, 10-20 parts of clay, 5-7 parts of aluminum hydroxide, 30-40 parts of water, and 1-3 parts of an oxalic acid inhibitor. The invention also particularly discloses a production method of the multifunctional wear-resistant fireproof adhesive. The multifunctional wear-resistant fireproof adhesive produced herein is suitable for adhesion of various wear-resistant articles and heat-resistant parts, has high adhesive strength and flexural and compressive strength, and the problems are effectively solved, for example, a lining of a fluidized-bed steel furnace has long maintenance time.

Owner:XINXIANG ZHONGNAN REFRACTORY THERMAL INSULATION MATERIAL

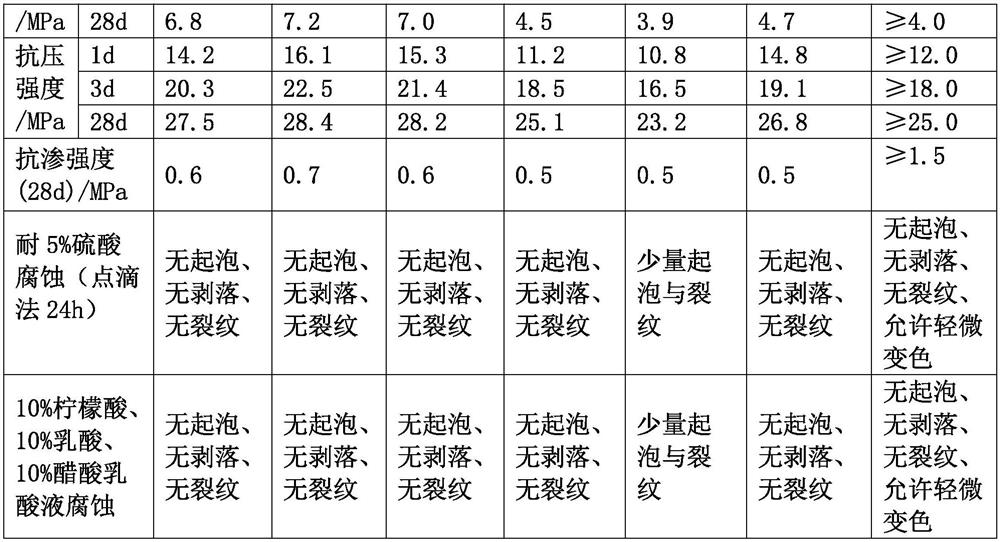

Bentonite modified aluminate inorganic anticorrosive mortar for pipe network repair and preparation method thereof

The invention discloses bentonite modified aluminate inorganic anticorrosive mortar for pipe network repair and a preparation method thereof. The preparation method comprises the following steps of preparing dry powder: mixing 100-120 parts by mass of Portland cement, 20-30 parts by mass of high-resistance aluminate cement, 60-80 parts by mass of quartz sand, 40-50 parts by mass of river sand, 1-5 parts by mass of a water reducing agent,1-3 parts by mass of steel fiber, and1-3 parts by mass ofpolyanionic cellulose, and uniformly stirring, continuously stirring the obtained dry powder, and adding 50-60 parts of water while stirring, adding 2-5 parts of self-made bentonite slurry, and stirring for 5-10 minutes at the speed of 200-400 r / min to form a mortar product. The self-made bentonite slurry is prepared by uniformly mixing 8-10 parts of high-viscosity bentonite, 0.2-0.5 part of sodium carbonate and 95-100 parts of water in proportion, stirring and puffing; the high-viscosity bentonite is high-viscosity organic bentonite prepared by modifying organic quaternary ammonium salt. By setting the components, the prepared mortar is higher in water-retaining property, thixotropy and adhesive capacity, shorter in setting time, higher in flexural and compressive strength and higher in corrosion resistance.

Owner:MUNICIPAL ENVIRONMENTAL PROTECTION ENG CO LTD OF CREC SHANGHAI GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com