ABS plastic floor board

A technology of ABS plastics and flooring, which is applied in the direction of architecture, building structure, flooring, etc., can solve the problems of no home decoration flooring, etc., achieve good comprehensive physical and mechanical properties, good engineering quality, and expand the effect of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

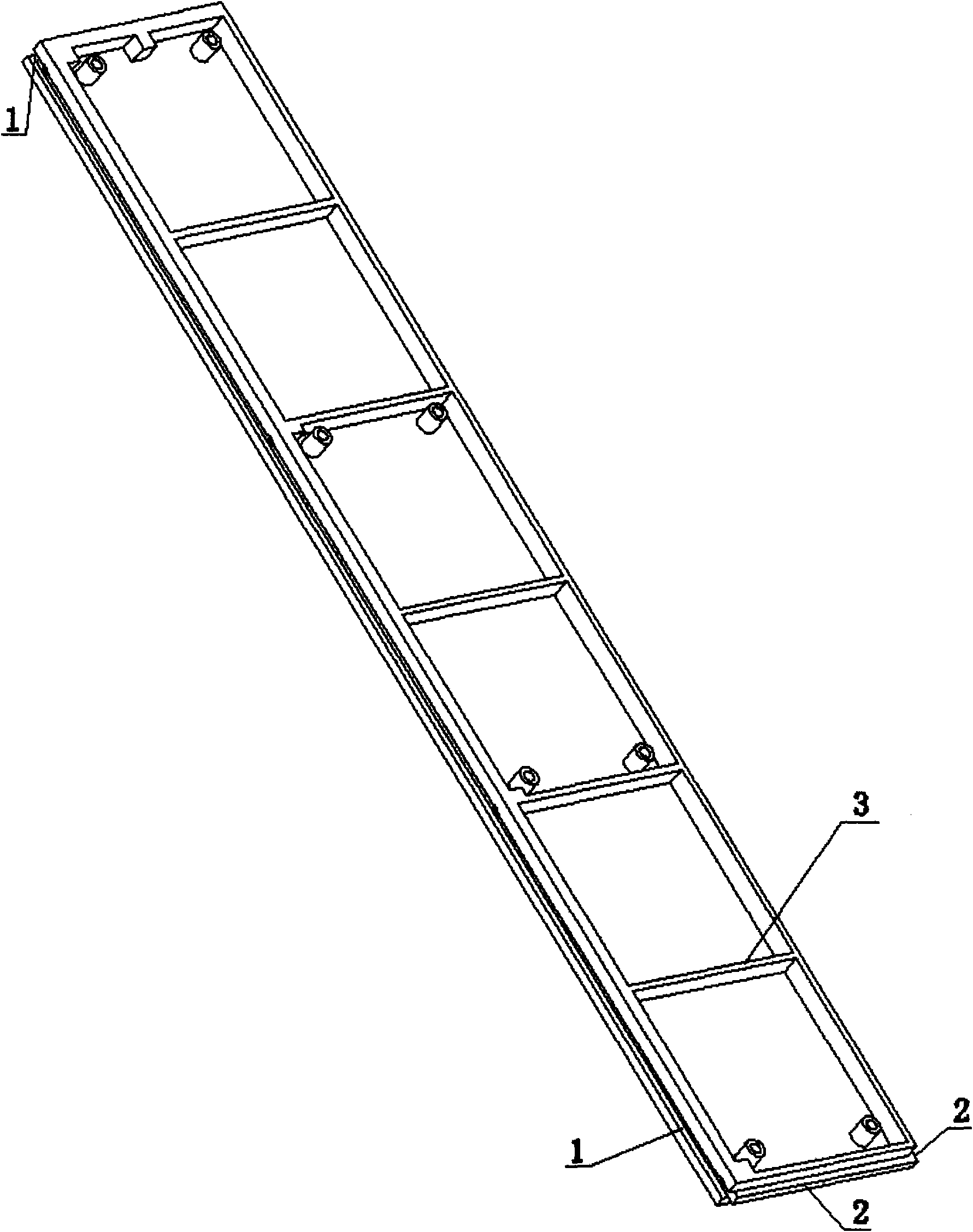

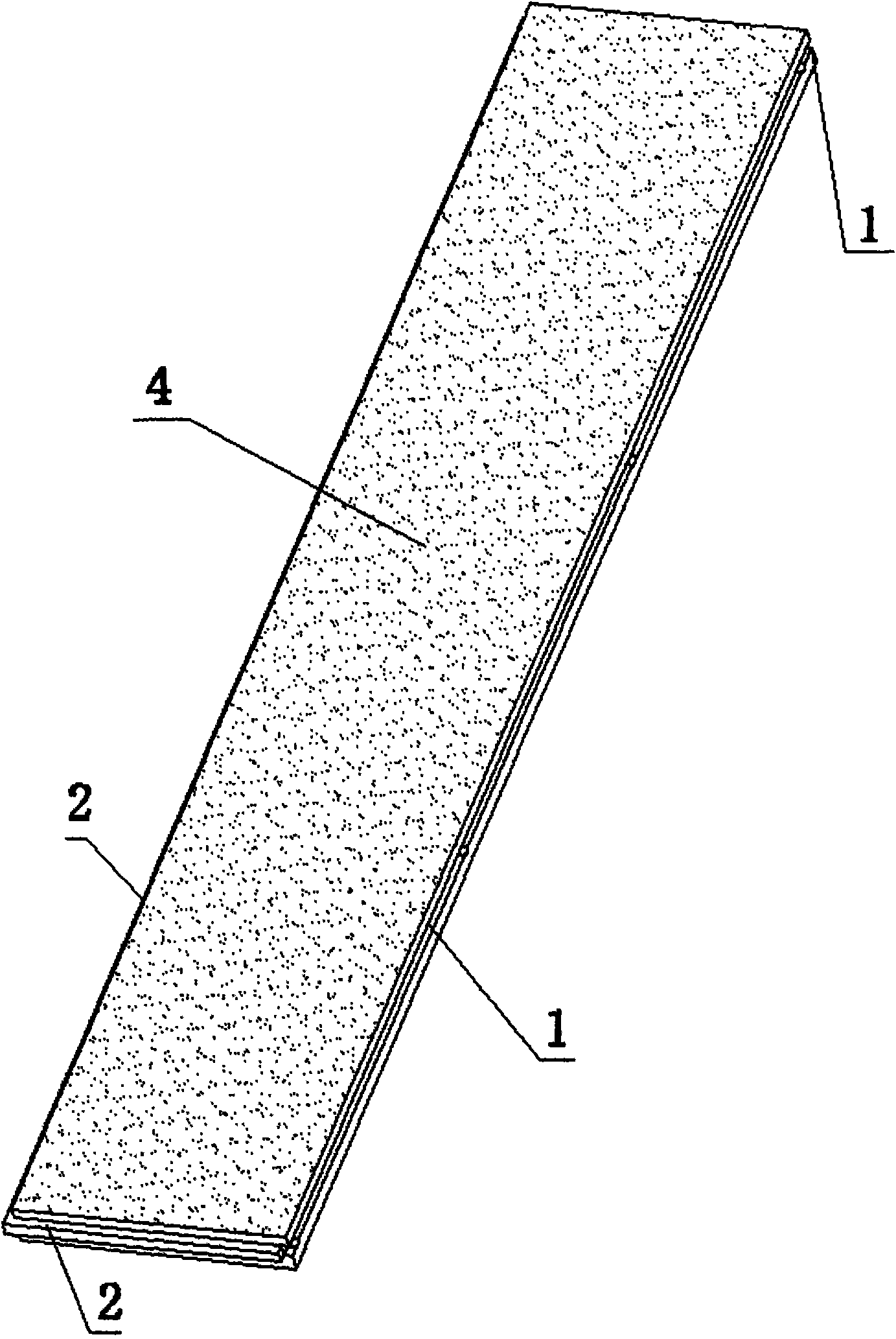

[0013] Embodiment 1: as figure 1 , figure 2 Shown, a kind of ABS plastic floor, it is prepared by ABS plastic injection molding technology, and described ABS plastic is the ternary copolymer that acrylonitrile, butadiene, styrene form, wherein the weight portion of three kinds of raw materials is formulated The ratio is: 20 parts of butadiene, 25 parts of acrylonitrile, 55 parts of styrene. The surface shape of the ABS plastic floor is rectangular, and its upper surface is made of anti-skid leather pattern 4, two adjacent edges have raised strips 2, the other two edges have grooves 1, and its lower surface has strip-shaped reinforcing ribs 3.

Embodiment 2

[0014] Embodiment 2: Others are the same as in Embodiment 1, the proportioning by weight of the three raw materials of acrylonitrile, butadiene and styrene is: 15 parts of butadiene, 20 parts of acrylonitrile, and 65 parts of styrene.

Embodiment 3

[0015] Embodiment 3: Others are the same as in Embodiment 1, the proportioning by weight of the three raw materials of acrylonitrile, butadiene and styrene is: 25 parts of butadiene, 25 parts of acrylonitrile, and 50 parts of styrene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com