Bottom layer brushing gypsum and application thereof

A technology for plastering gypsum and bottom layer, which is applied in the field of comprehensive utilization of chemical building materials and solid waste, and can solve the problems that the strength and hardness cannot meet the specific construction requirements, the formulation performance and optimization have been deeply studied, and the anti-cracking performance has decreased. Inhibition of shrinkage cracking, outstanding cost-effectiveness, and high flexural and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

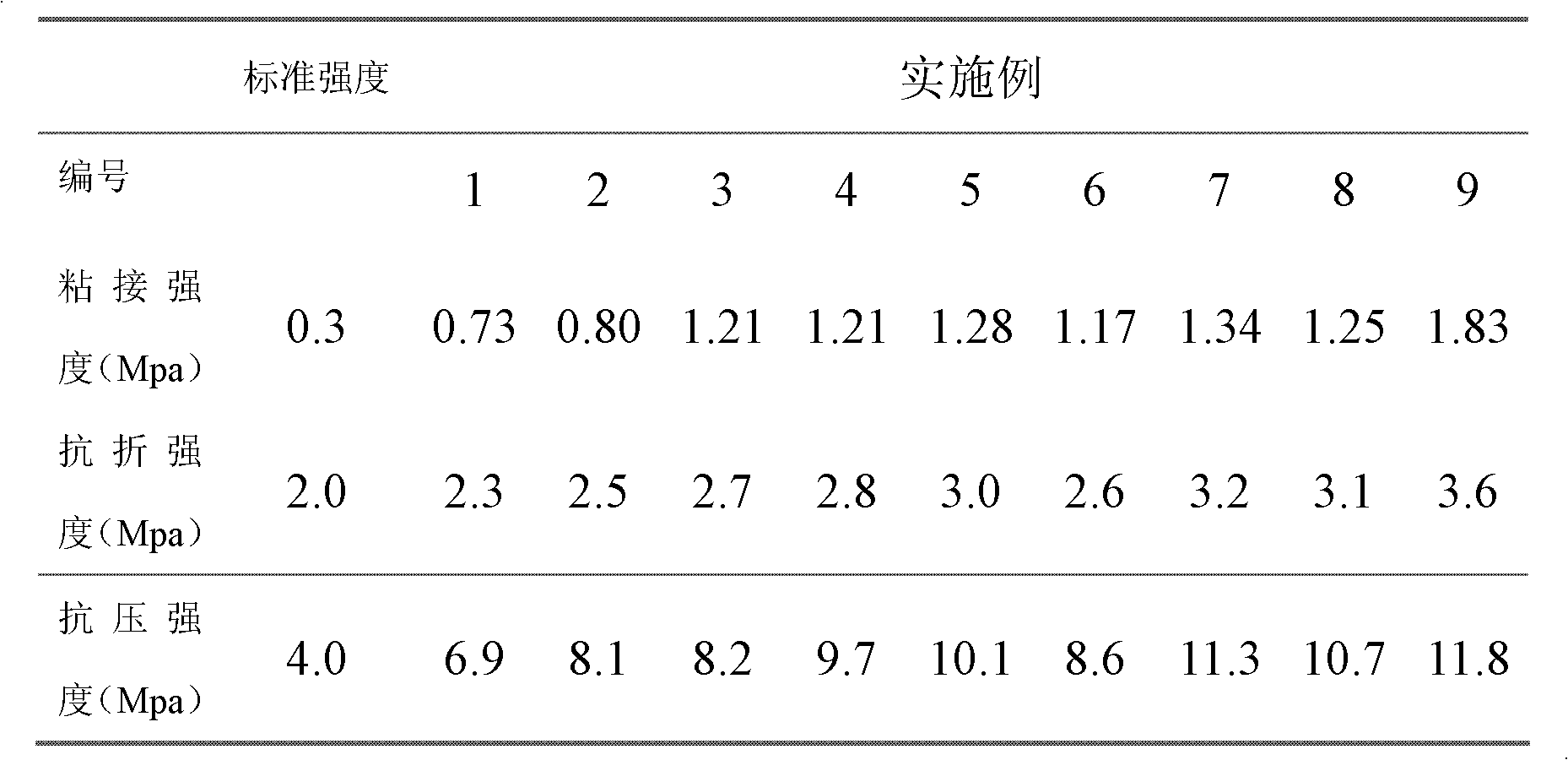

Examples

Embodiment 1

[0059] Dosage of each component:

[0060] Construction gypsum 200kg 30 mesh quartz sand 360kg

[0061] 45 mesh quartz sand 150kg 60 mesh quartz sand 275kg

[0062] HPMC70000 3kg

[0063] Sodium-based bentonite (Zhejiang Yuhang Jiacheng Nonmetallic Mining Co., Ltd., the same below) 5kg

[0064] Retardan P 0.2kg ARBOCEL ZZC500 2kg

[0065] VINNAPAS5044N 5kg

[0066] Mix with non-gravity double-flying knife mixing equipment to prepare the bottom plaster.

Embodiment 2

[0068] Dosage of each component:

[0069] Construction gypsum 250kg 30 mesh quartz sand 335kg

[0070] 45 mesh quartz sand 150kg 60 mesh quartz sand 250kg

[0071] HPMC70000 3kg Sodium bentonite 5kg

[0072] Retardan P 0.25kg ARBOCEL ZZC500 2kg

[0073] VINNAPAS5044N 5kg

[0074] Mix with non-gravity double-flying knife mixing equipment to prepare the bottom plaster.

Embodiment 3

[0076] Dosage of each component:

[0077] Construction gypsum 300kg 30 mesh quartz sand 350kg

[0078] 45 mesh quartz sand 85kg 60 mesh quartz sand 250kg

[0079] HPMC70000 3kg Sodium bentonite 5kg

[0080] Retardan P 0.3kg ARBOCEL ZZC500 2kg

[0081] VINNAPAS5044N 5kg

[0082] Mix with non-gravity double-flying knife mixing equipment to prepare the bottom plaster.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| wet compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com