Recycled cement concrete prepared by recycling waste asphalt, and preparation method and application thereof

A technology for waste asphalt and recycled cement, which is applied in solid waste management, climate change adaptation, sustainable waste treatment, etc. Corrosion and frost resistance, weight reduction, improved workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

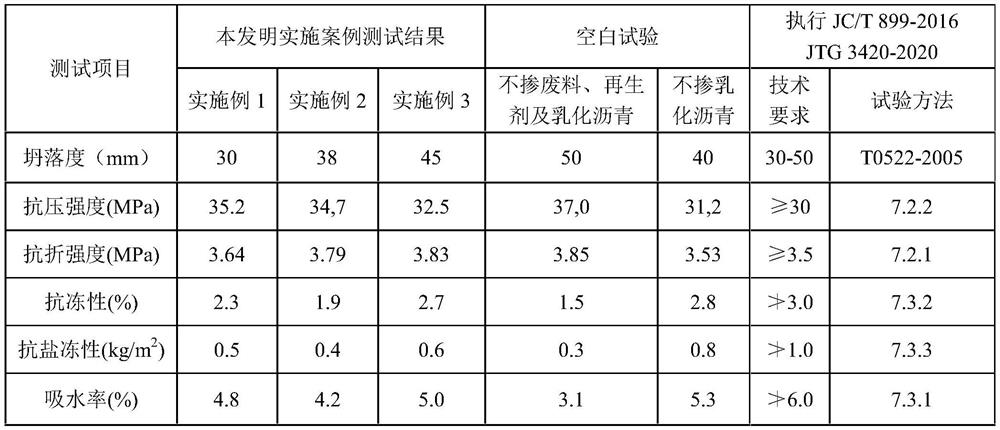

Examples

Embodiment 1

[0036] A regenerated cement concrete for reuse of waste asphalt, comprising A component, B component, C component, D component and E component, and the mass ratio of each component is: A component is 13-20 60-80 parts for component B, 25-35 parts for component C, 1.28-1.98 parts for component D, and 5-8 parts for component E.

[0037] in:

[0038] Component A is composed of cement, a cementitious material, and a reinforcing and toughening material, and its mass ratio is: 12.888-19.886 parts of cement, and 0.112-0.144 parts of reinforcing and toughening material.

[0039] The cement is Portland cement or ordinary Portland cement of grade 42.5 or above; the reinforcing and toughening material is carbon fiber waste silk.

[0040] Component B is coarse aggregate and fine aggregate for cement concrete, and its mass ratio is: 32.5-52.5 parts of coarse aggregate and 27.5 parts of fine aggregate; the nominal maximum particle size of coarse aggregate is not more than 30mm, The nomina...

Embodiment 2

[0049] This example is an engineering component such as recycled cement concrete curbstones for recycling waste asphalt mixture, and its preparation method includes the following steps:

[0050] S1. Preparation of component A: cut 0.13 parts of carbon fiber waste silk to the required length, and mix it with 15 parts of cement in a certain proportion.

[0051] S2, Preparation of component C: After drying dimethyl sulfoxide, spray 0.046 parts of dimethyl sulfoxide evenly on the surface of 23 parts of waste asphalt mixture, and wait for the waste asphalt on the surface to dissolve; use 2 parts of water Dilute 2 parts of emulsified asphalt evenly in advance; pour the former into the latter and stir together for 1-2min;

[0052] S3. Preparation of component E: Dissolve 0.316 parts of surfactant in 6 parts of water in advance and stir evenly to prepare an aqueous solution of surfactant for later use.

[0053] S4. Mixing: Pour 40 parts of coarse aggregate and 27.5 parts of fine aggr...

Embodiment 3

[0056] The preparation method of engineering components such as recycled cement concrete curbs and other engineering components of waste asphalt mixture resource utilization in this embodiment includes the following steps:

[0057] S1. Preparation of component A: cut 0.119 parts of carbon fiber waste silk to the required length, and mix it with 14.9 parts of cement in a certain proportion.

[0058] S2, Preparation of component C: After drying dimethyl sulfoxide, spray 0.048 parts of dimethyl sulfoxide evenly on the surface of 24 parts of waste asphalt mixture, and wait for the waste asphalt on the surface to dissolve; use 2.5 parts of water Dilute 3 parts of emulsified asphalt evenly in advance; pour the former into the latter and stir together for 1-2min;

[0059] S3. Preparation of component E: Dissolve 0.3 parts of surfactant in 5.7 parts of water in advance and stir evenly to prepare an aqueous solution of surfactant for later use.

[0060] S4. Mixing: Pour 45 parts of co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com