Organic glass material and preparation method thereof

A technology of plexiglass and glass powder, applied in the field of plexiglass materials and their preparation, can solve the problems of easy rubbing, insufficient surface hardness, brittle texture, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

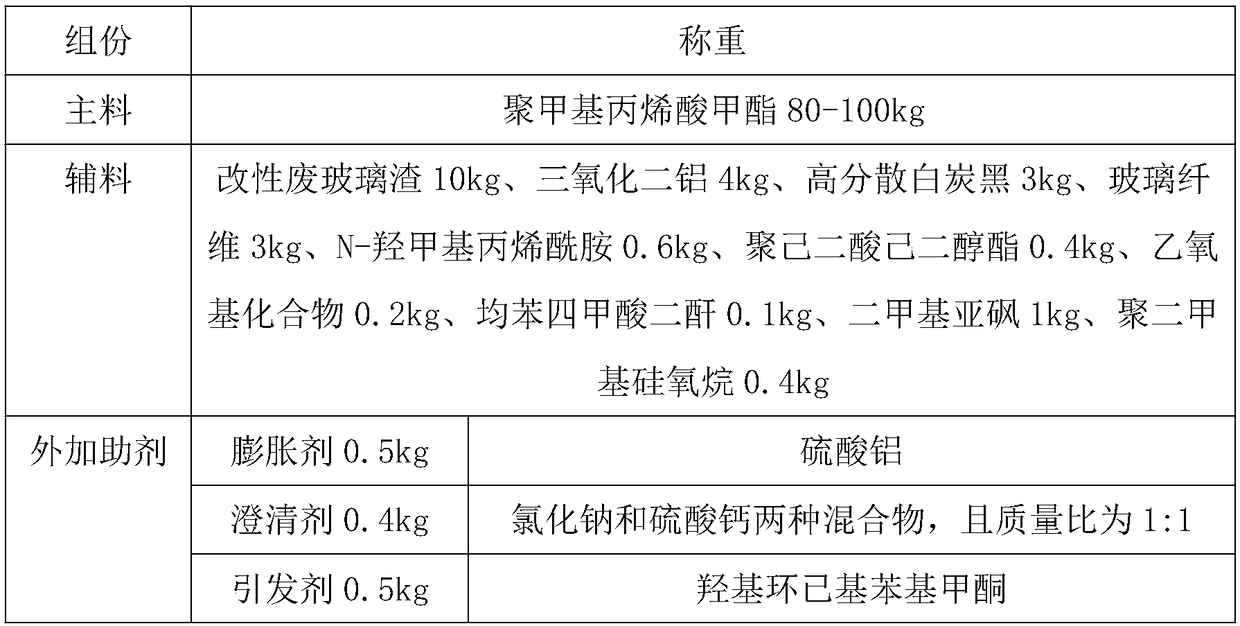

[0023] A kind of plexiglass material, takes the raw material of following table 1:

[0024] Table 1

[0025]

[0026]

[0027] The aluminum oxide, highly dispersed white carbon black, and glass fiber selected above are all nano-scale materials;

[0028] Preparation of modified waste glass slag:

[0029] (1) Take 10 kg of waste glass slag raw material and place it in a ball mill to grind and pulverize it, pass through an 80-mesh sieve and transport it to a heat treatment furnace, and heat treat it for 60 minutes at a temperature of 180° C. to obtain glass powder;

[0030] (2) Add 0.3kg of fluorspar powder, 0.4kg of sanidine powder and 0.1kg of tetra-n-butyl titanate to the glass powder, mix them evenly, transport them to the muffle furnace, and calcinate them at a temperature of 320°C After 50 minutes, after cooling down to 80°C with the furnace, add 0.3kg of dipentaerythritol and 0.1kg of sodium polyacrylate to the glass powder and stir evenly, heat preservation, stand...

Embodiment 2

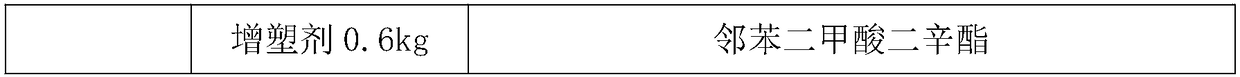

[0033] A kind of plexiglass material, takes the raw material of following table 2:

[0034] Table 2

[0035]

[0036] The aluminum oxide, highly dispersed white carbon black, and glass fiber selected above are all nano-scale materials;

[0037] Preparation of modified waste glass slag:

[0038] (1) Take 15kg of waste glass slag raw material and place it in a ball mill to grind and pulverize it, pass it through a 90-mesh sieve and transport it to a heat treatment furnace, and heat treat it at 200°C for 70 minutes to obtain glass powder;

[0039] (2) Add 0.6kg of fluorspar powder, 0.45kg of sanidine powder and 0.3kg of tetra-n-butyl titanate to the glass powder, mix them evenly, transport them to the muffle furnace, and calcine them at a temperature of 330°C After 55min, after cooling down to 85°C with the furnace, add 0.6kg of dipentaerythritol and 0.3kg of sodium polyacrylate to the glass powder, stir evenly, keep warm, let stand and age for 4h to carry out chemical modif...

Embodiment 3

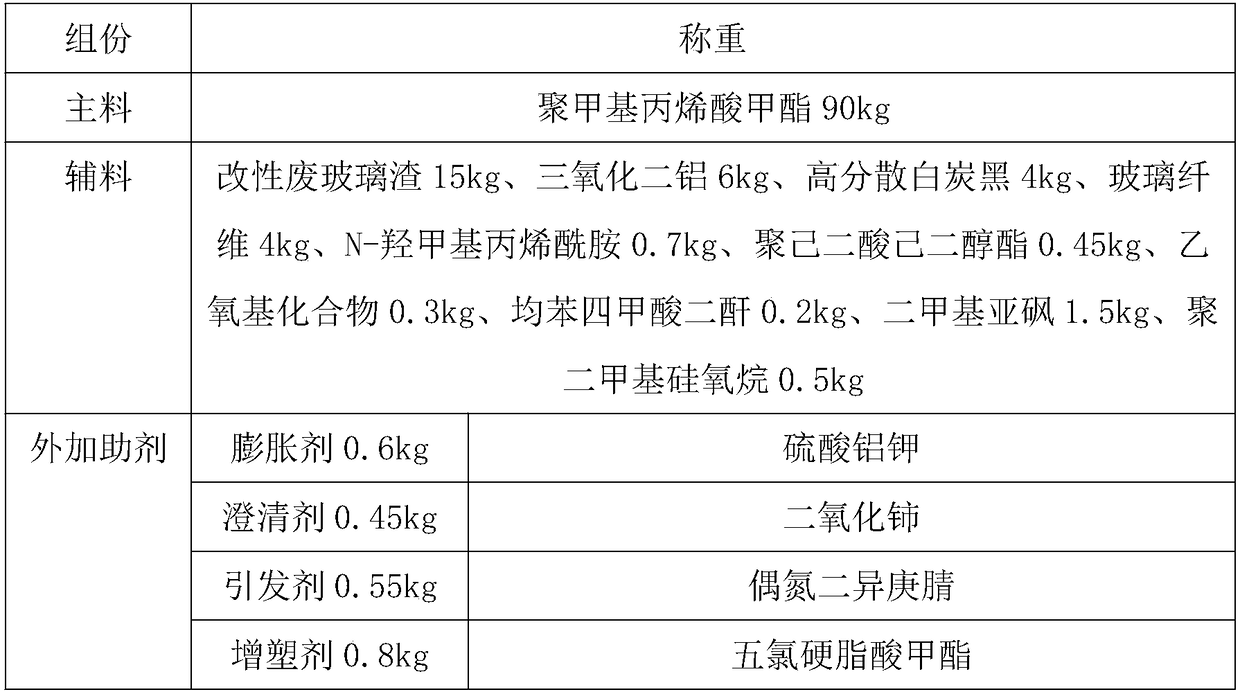

[0042] A kind of plexiglass material, takes the raw material of following table 3:

[0043] table 3

[0044]

[0045] The aluminum oxide, highly dispersed white carbon black, and glass fiber selected above are all nano-scale materials;

[0046] Preparation of modified waste glass slag:

[0047] (1) Take 20kg of waste glass slag raw material and place it in a ball mill to grind and pulverize it, pass through a 100-mesh sieve and transport it to a heat treatment furnace, and heat treat it for 80 minutes at a temperature of 220°C to obtain glass powder;

[0048] (2) Add 1kg of fluorspar powder, 1.2kg of sanidine powder and 0.6kg of tetra-n-butyl titanate to the glass powder, mix them evenly, transport them to the muffle furnace, and calcinate them at 340°C for 60min , after cooling down to 90°C with the furnace, add 1kg of dipentaerythritol and 0.6kg of sodium polyacrylate to the glass powder, stir evenly, keep warm, let stand and age for 4.5h to carry out chemical modificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com