Preparation method of microcrystal glass

A technology of glass-ceramics and cullet, which is applied in glass manufacturing equipment, glass molding, glass rolling, etc., can solve the problems of small space for glass-ceramics, inhibit the development of glass-ceramics, and is not easy to process and shape. Good product consistency, low production cost, and the effect of reducing the output of smelting energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

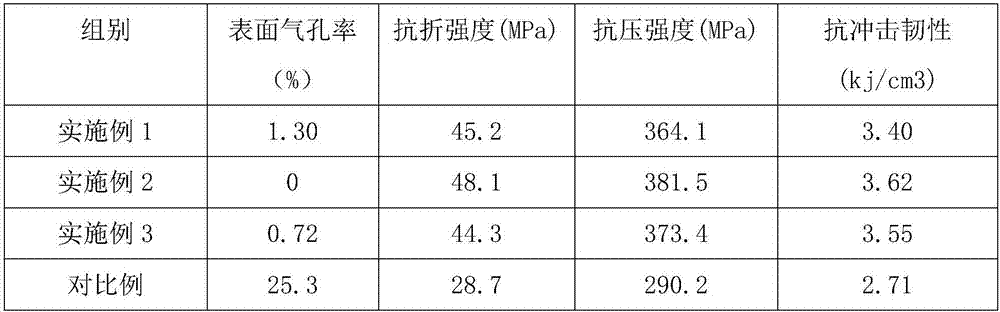

Examples

Embodiment 1

[0024] A preparation method of glass-ceramics, carried out according to the following steps:

[0025] (1) Weighing: Weigh the following raw materials for use: cullet 40kg, coal gangue 20kg, sanidine 15kg, anorthite 15kg, barium feldspar 15kg, sodium zeolite 15kg, borax 5kg, titanium dioxide 4kg, sodium fluorosilicate 4kg, alumina 6kg, zinc oxide 4kg, lanthanum trioxide 3kg and clarifier 1kg;

[0026] The above clarifying agent adopts two mixtures of sodium chloride and calcium sulfate, and the mass ratio between the two is 1:1;

[0027] (2) Smelting crystallization: first transport all raw materials except clarifier to the glass melting furnace, then raise the temperature of the glass melting furnace to the melting temperature of 1240°C at a rate of 40°C / min, and keep it warm for 100min to obtain glass melt;

[0028] (3) Stirring and clarification: then add the clarifier to the glass melt and stir to melt, and the stirring speed is 50r / min, the stirring time is 40min, and the...

Embodiment 2

[0032] A preparation method of glass-ceramics, carried out according to the following steps:

[0033] (1) Weighing: Weigh the following raw materials for use: cullet 50kg, coal gangue 30kg, sanidine 20kg, anorthite 20kg, barium feldspar 20kg, sodium zeolite 20kg, borax 10kg, titanium dioxide 6kg, sodium fluorosilicate 5kg, 8kg of alumina, 6kg of zinc oxide, 4kg of dilanthanum trioxide and 3kg of clarifying agent;

[0034] The above clarifying agent adopts three mixtures of antimony oxide, ammonium nitrate and cerium dioxide, and the mass ratio between the three is 1:2:1;

[0035] (2) Smelting crystallization: first transport all raw materials except clarifier to the glass melting furnace, then raise the temperature of the glass melting furnace to the melting temperature of 1300°C at a rate of 50°C / min, and keep it warm for 110min to obtain the glass melt;

[0036] (3) Stirring and clarification: then add the clarifier to the glass melt and stir to melt, and the stirring speed...

Embodiment 3

[0040] A preparation method of glass-ceramics, carried out according to the following steps:

[0041] (1) Weighing: Weigh the following raw materials for use: 60kg of cullet, 40kg of coal gangue, 25kg of sanidine, 25kg of anorthite, 25kg of feldspar, 25kg of sodium zeolite, 15kg of borax, 8kg of titanium dioxide, and sodium fluorosilicate 6kg, 10kg of alumina, 8kg of zinc oxide, 5kg of dilanthanum trioxide and 5kg of cerium dioxide clarifying agent;

[0042] (2) Smelting crystallization: first transport all raw materials except clarifier to the glass melting furnace, then raise the temperature of the glass melting furnace to the melting temperature of 1360°C at a rate of 60°C / min, and keep it warm for 120min to obtain the glass melt;

[0043] (3) Stirring and clarification: then add the clarifier to the glass melt and stir to melt, and the stirring speed is 70r / min, the stirring time is 60min, and then stand for clarification treatment for 3h;

[0044] (4) Compression molding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com