Motorcycle clutch release travel adjusting mechanism

A separation stroke and adjustment mechanism technology, which is applied in the direction of friction clutch, clutch, mechanical drive clutch, etc., can solve the problems of inconsistent displacement, large tolerance, increased parts processing technology and manufacturing difficulty, so as to improve reliability and ensure separation stroke , the effect of eliminating size differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

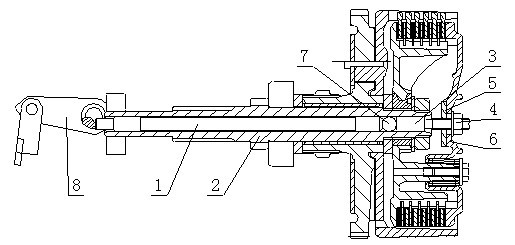

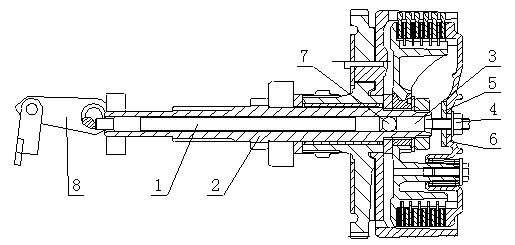

[0016] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] Such as figure 1 As shown, a motorcycle clutch separation stroke adjustment mechanism includes a push rod 1, and the push rod 1 is slidably arranged in the push rod installation sleeve 2, and also includes an adjusting screw 3, a locking nut 4, and an adjusting nut 5. One end of the adjusting screw 3 is slidably located in the mandrel mounting sleeve 2 and is offset against the mandrel 1, and the other end of the adjusting screw 3 is provided with a through hole on the pressure plate 6 facing the adjusting screw 3, and the through hole is fixed. The adjustment nut 5 is described, the end of the adjustment screw 3 away from the push rod 1 is screwed into the adjustment nut 5 and the lock nut 4 is screwed after passing through the through hole, and the lock nut 4 faces the side of the pressure plate 6 The surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com