External etching compensation method for precision circuit

A compensation method and external compensation technology, applied in chemical/electrolytic methods to remove conductive materials, printed circuits, printed circuit manufacturing, etc., can solve problems such as difficult, complex, and complex operations, and achieve simple compensation rules and convenient design , The effect of low design work difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below. However, it should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the scope of the present invention.

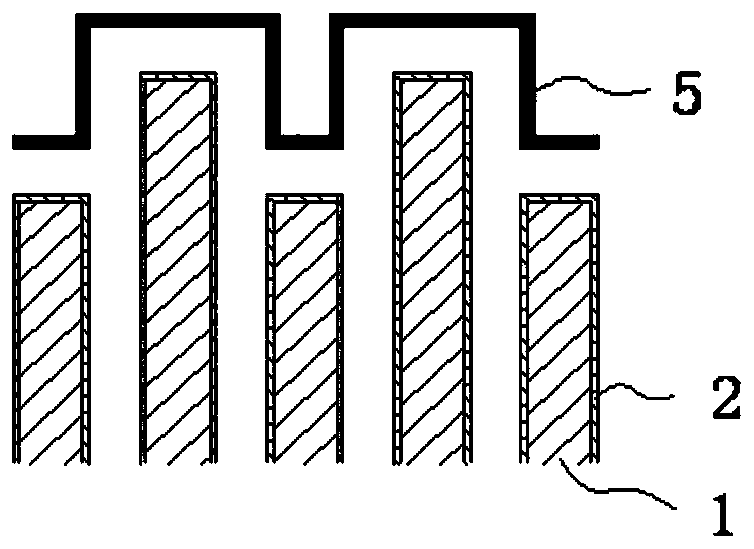

[0022] An external etching compensation method for precision circuits. Firstly, a uniform blank area is formed around the circuit. During etching, the density of the area where the circuit is located is the same, and the etching effect is consistent. After etching, a uniform circuit is obtained.

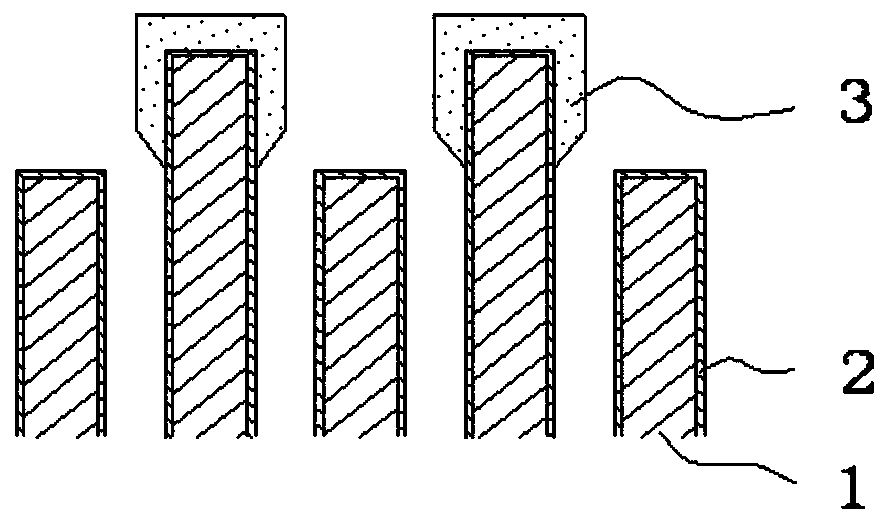

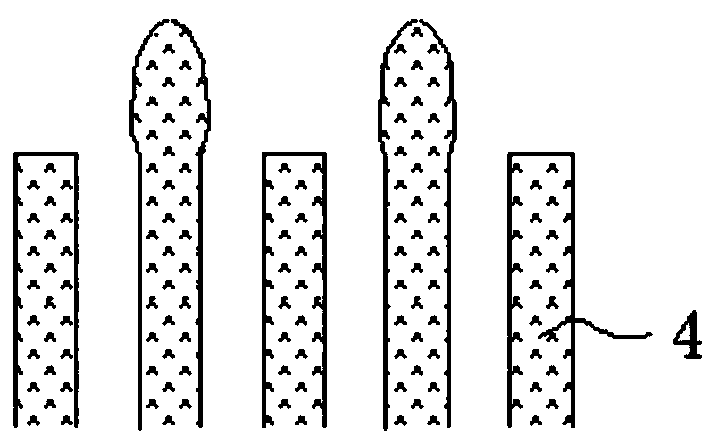

[0023] Specifically, such as image 3 As shown, when there are long and short lines arranged in a staggered manner, first perform conventional compensation 2 on the entire line, and then perform external compensation 15 at a certain distance from the front end of each line and the side of the long line, and obtain a uniform lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com