Prestress pipeline grouting agent, preparation method and grouting material

A prestressed pipeline and grouting agent technology, which is applied in the field of grouting agent preparation, can solve problems such as increased transportation costs, and achieve the effects of good fluidity, high structural strength, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 8

[0092] Prestressed pipeline grouting agent, the difference between Example 8 and Example 4 is that the polycarboxylate water reducer is replaced by a naphthalene-based high-efficiency water reducer.

Embodiment 9

[0094] Prestressed pipeline grouting agent, the difference between embodiment 9 and embodiment 4 is that the ore powder is replaced by coal ash.

[0095] The preparation method of the prestressed pipeline grouting agent is to weigh each component according to the above table, and mix each component evenly.

[0096] Prestressed pipeline grouting material, the grouting agent prepared by embodiment 1-9 and comparative example 1-3 is mixed with road-specific cement and water, wherein the weight ratio of grouting agent and cement is 1:9, The weight ratio of the sum of the weight parts of the grouting agent and cement to the water is 1:0.28 to obtain the prestressed pipeline pressure grout.

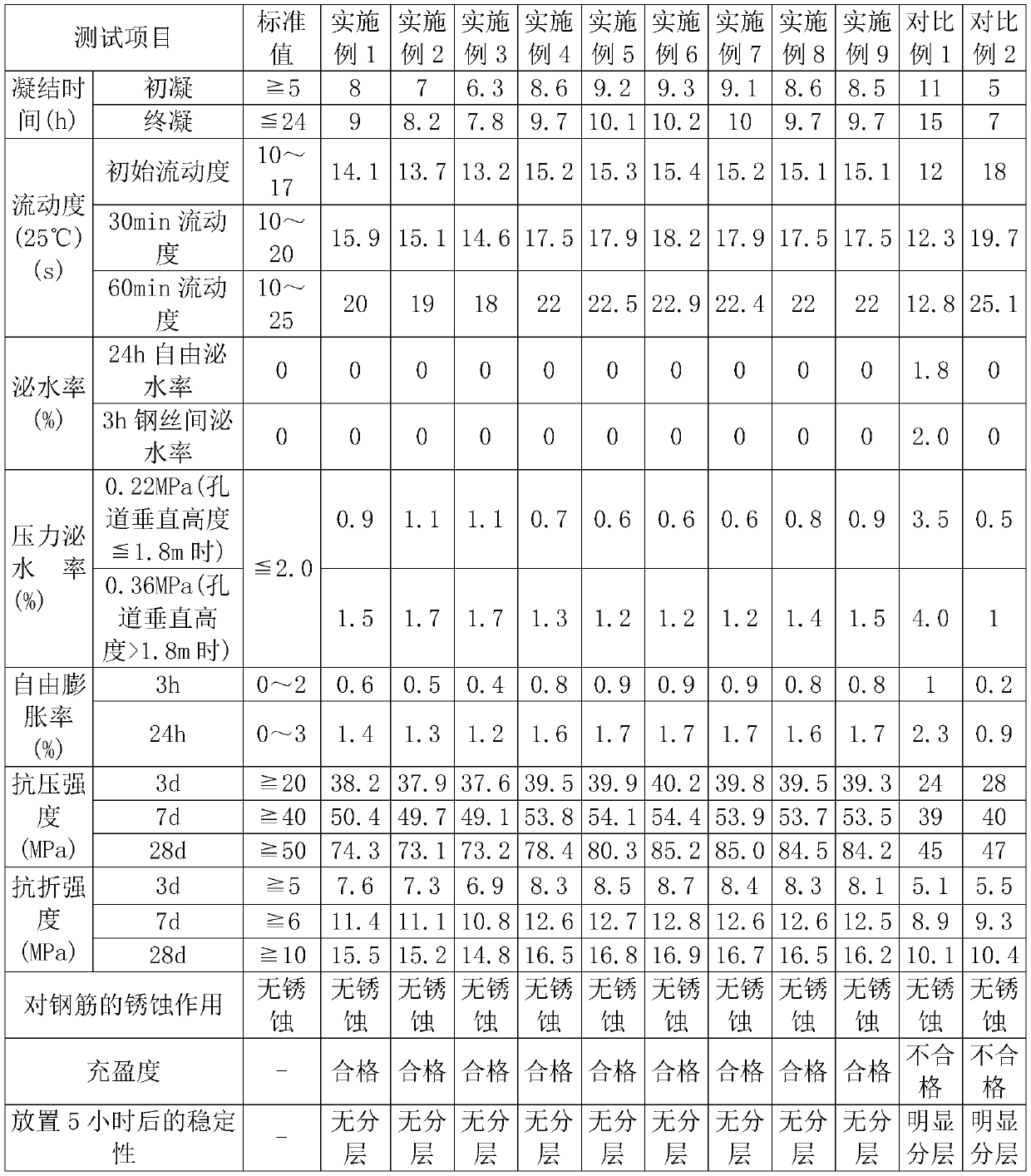

[0097] The various indicators of the prestressed pipeline grouting material are tested, and the grouting material is made into a test block for testing. The testing basis is JTG / T F50-2011 "Technical Specifications for Highway Bridge and Culvert Construction" and the specific data are as follow...

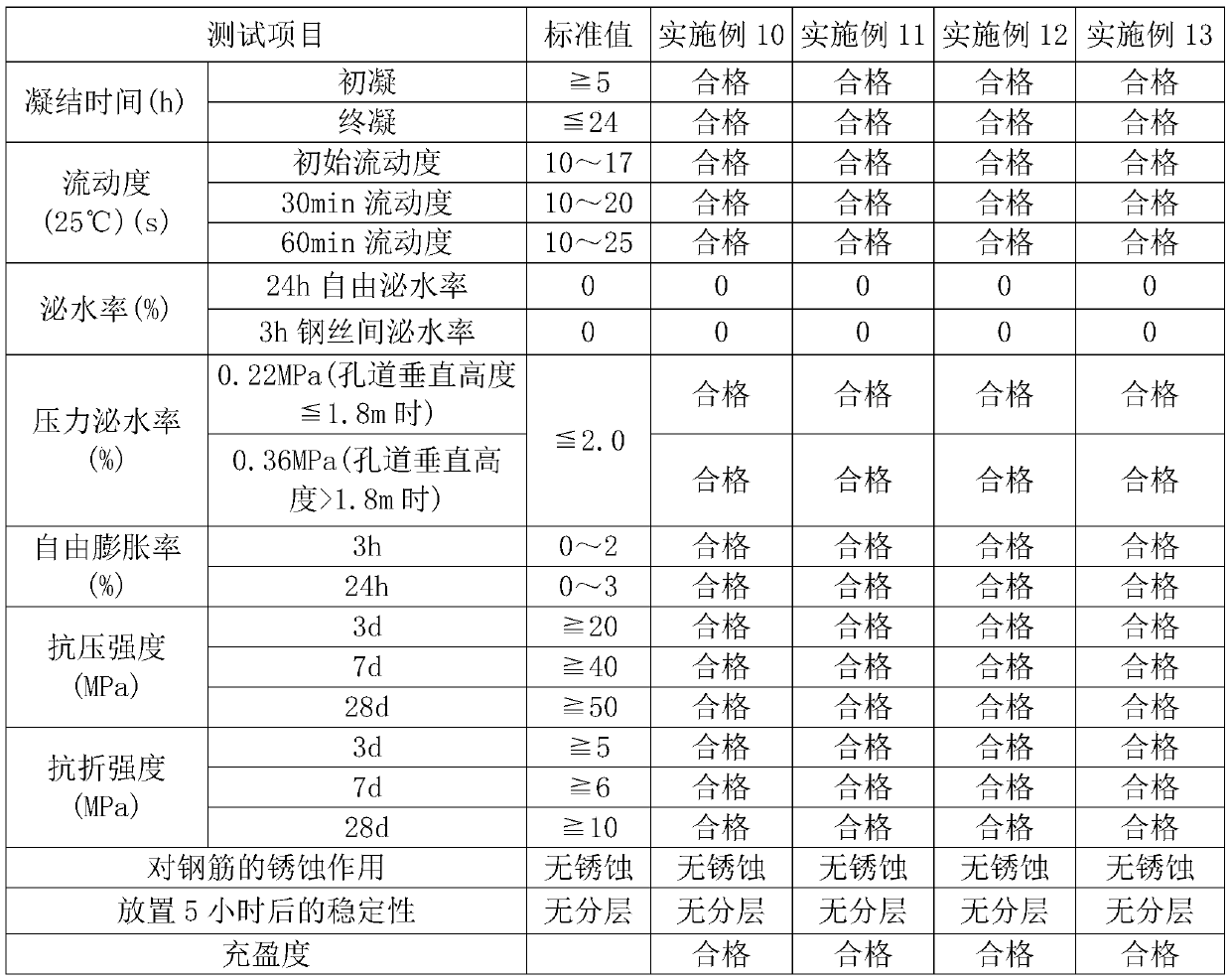

Embodiment 10

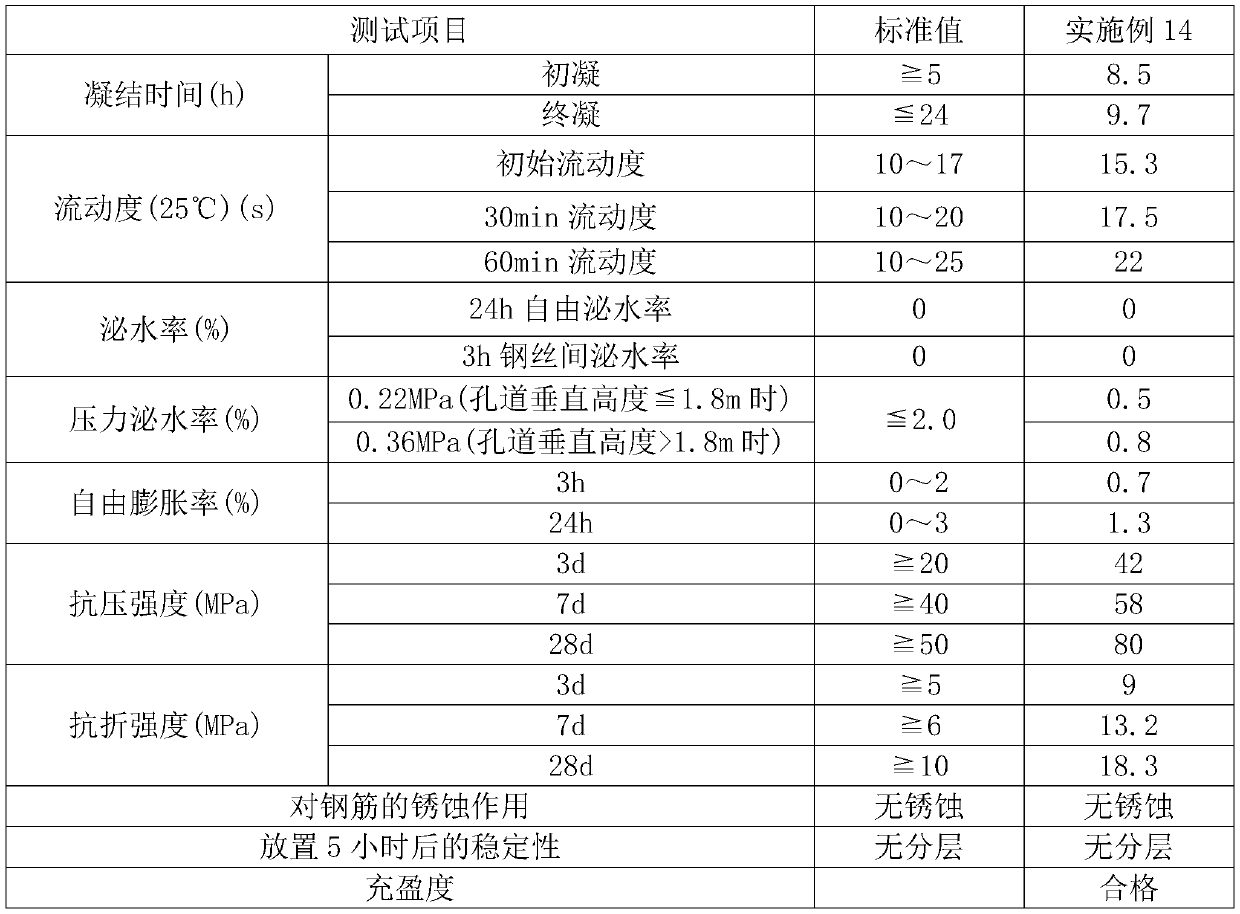

[0105] Squeeze the grout, the grout that embodiment 4 is made mixes with dam cement, water, the weight proportion of grout and cement is 1:9, the sum of the parts by weight of grout and cement and water The weight ratio is 1:0.28.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com