High-strength self-leveling mortar terrace material for surface layer and preparation method

A self-leveling mortar and floor material technology, which is applied in the field of high-strength self-leveling mortar floor materials and preparations, can solve the problems of low mechanical strength, easy pulverization, and easy cracking, and achieve good mechanical strength, flexural and compressive resistance High strength and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

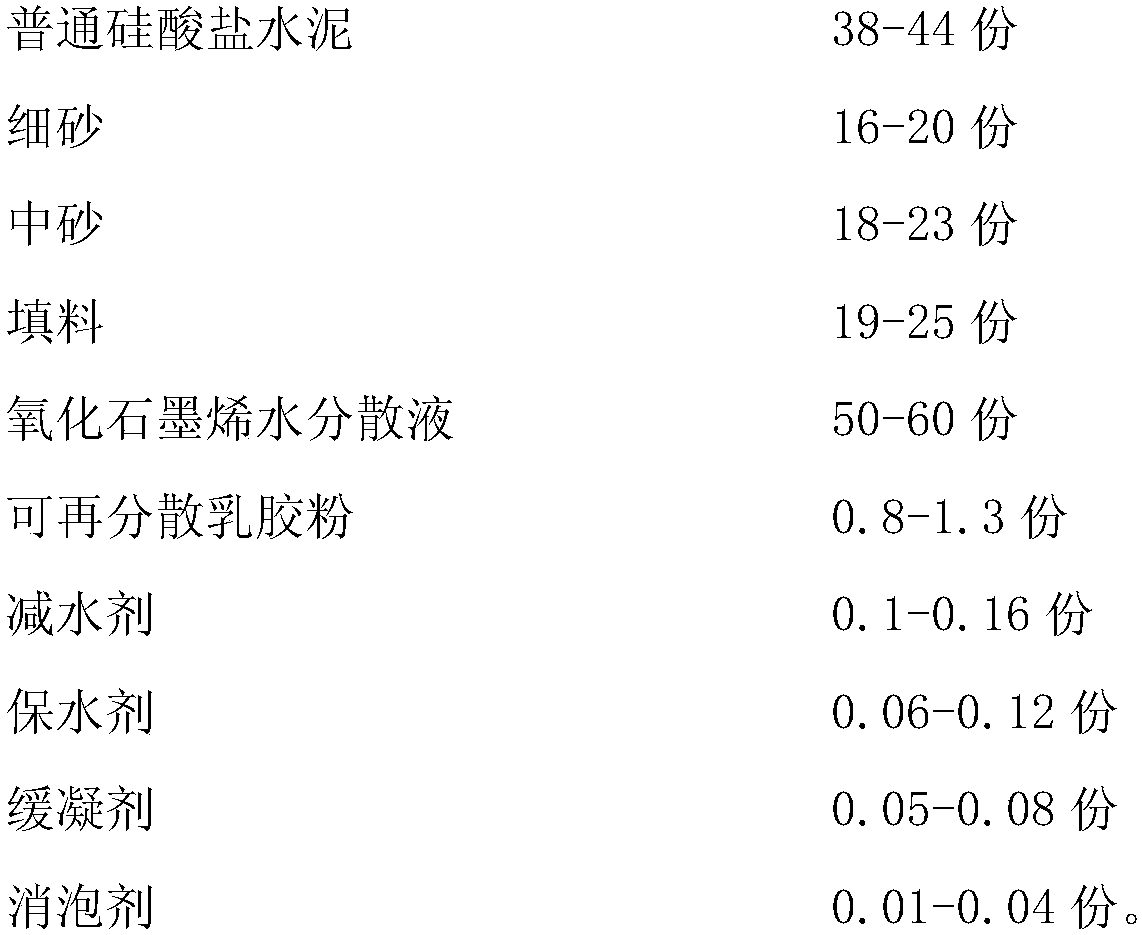

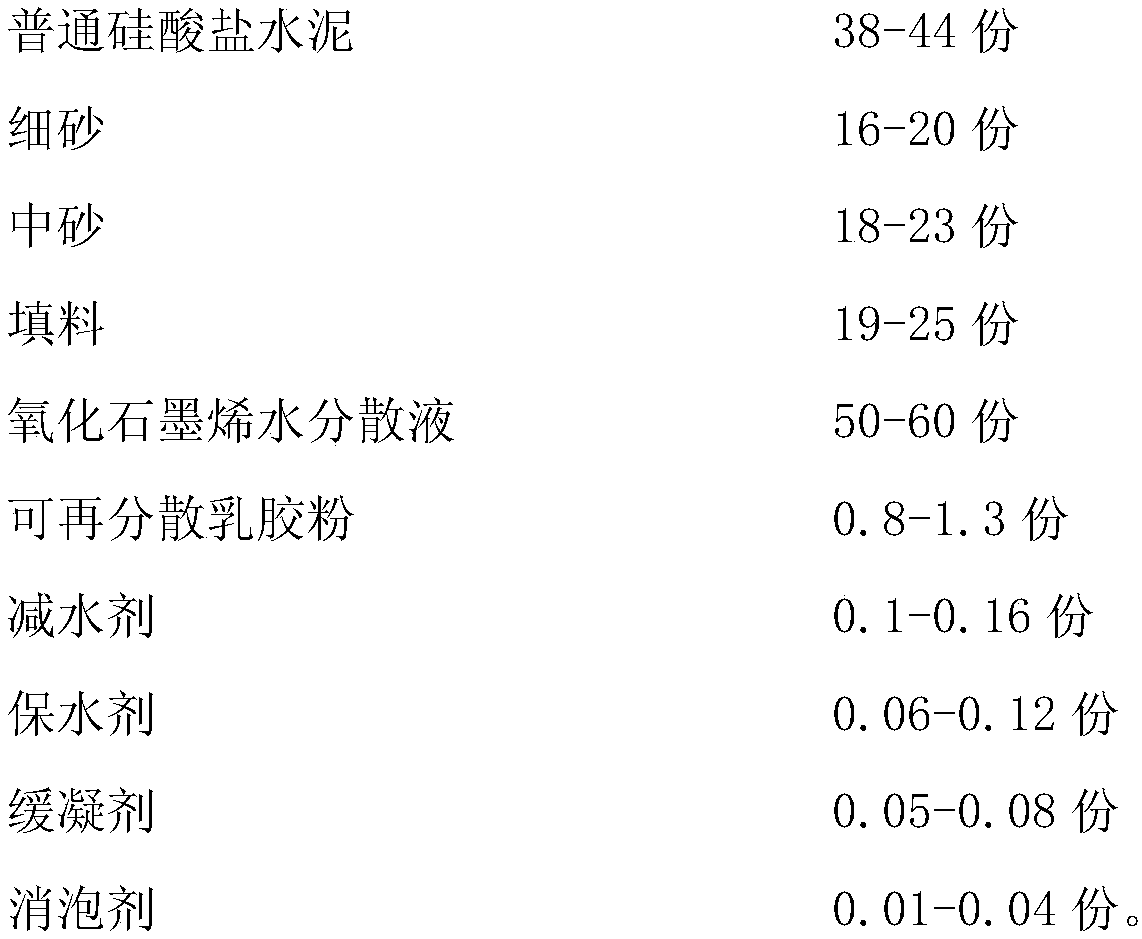

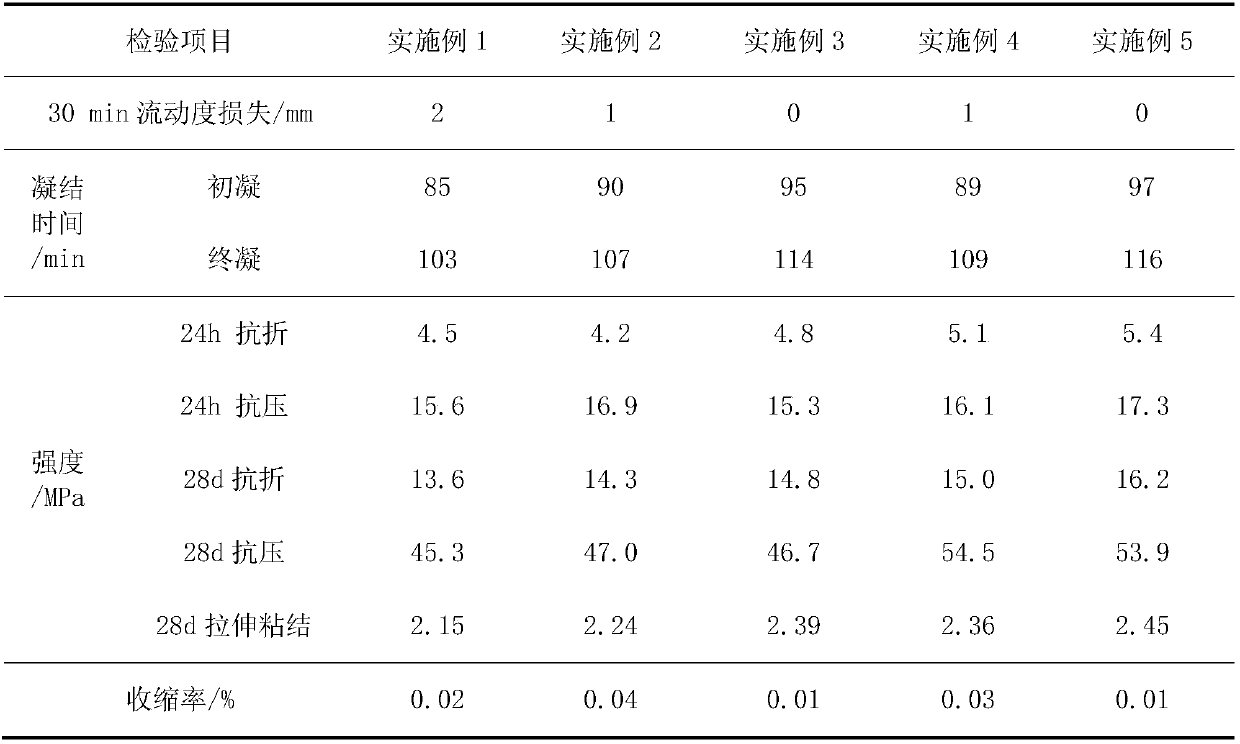

[0021] In terms of mass, the composition ratio is as follows: 38 parts of PⅡ42.5 cement, 17 parts of 70-90 mesh fine sand, 18 parts of 30-50 mesh medium sand, 19 parts of 300 mesh heavy calcium powder (calcium carbonate content is greater than 85%, Whiteness greater than 92), 51 parts of graphene oxide dispersion with a density of 7.4g / ml, "Wacker" 0.9 parts of redispersible latex powder, 0.1 parts of HY type polycarboxylate powder superplasticizer, 0.07 parts of hydroxypropyl methylcellulose ether water retaining agent (viscosity of 70000mpa.s), 0.06 parts of SG-10 gypsum retarder, P803 defoamer 0.02 parts, water-material mass ratio is 0.24; its performance is shown in Table 1 after testing.

Embodiment 2

[0023] In terms of mass, the composition ratio is as follows: 39 parts of PⅡ42.5 cement, 16 parts of 70-90 mesh fine sand, 19 parts of 30-50 mesh medium sand, 19 parts of 300 mesh heavy calcium powder (calcium carbonate content is greater than 85%, Whiteness greater than 92), 52 parts of graphene oxide dispersion with a density of 7.4g / ml, "Wacker" 0.8 parts of redispersible latex powder, 0.12 parts of HY type polycarboxylate powder superplasticizer, 0.06 parts of hydroxypropyl methylcellulose ether water retaining agent (viscosity of 70000mpa.s), 0.05 parts of SG-10 gypsum retarder, P803 defoamer 0.01 part, water-material mass ratio is 0.24; its performance is shown in Table 1 after testing.

Embodiment 3

[0025] In terms of mass, the composition ratio is as follows: 41 parts of PⅡ42.5 cement, 17 parts of 70-90 mesh fine sand, 20 parts of 30-50 mesh medium sand, 20 parts of 300 mesh heavy calcium powder (calcium carbonate content is greater than 85%, Whiteness greater than 92), 55 parts of graphene oxide dispersion with a density of 7.4g / ml, "Wacker" 1.0 parts of redispersible latex powder, 0.12 parts of HY type polycarboxylate powder superplasticizer, 0.10 parts of hydroxypropyl methylcellulose ether water retaining agent (viscosity of 70000mpa.s), 0.08 parts of SG-10 gypsum retarder, P803 defoamer 0.02 parts, water-material mass ratio is 0.24; its performance is shown in Table 1 after testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com