Patents

Literature

85results about How to "Play an emulsifying role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fermented fruit and vegetable composition containing probiotics and traditional Chinese medicine extract and preparation method of fermented fruit and vegetable composition

InactiveCN105249326AHealing speed upGreat tasteVitamin food ingredientsAcidic food ingredientsBiotechnologyAngelica Sinensis Root

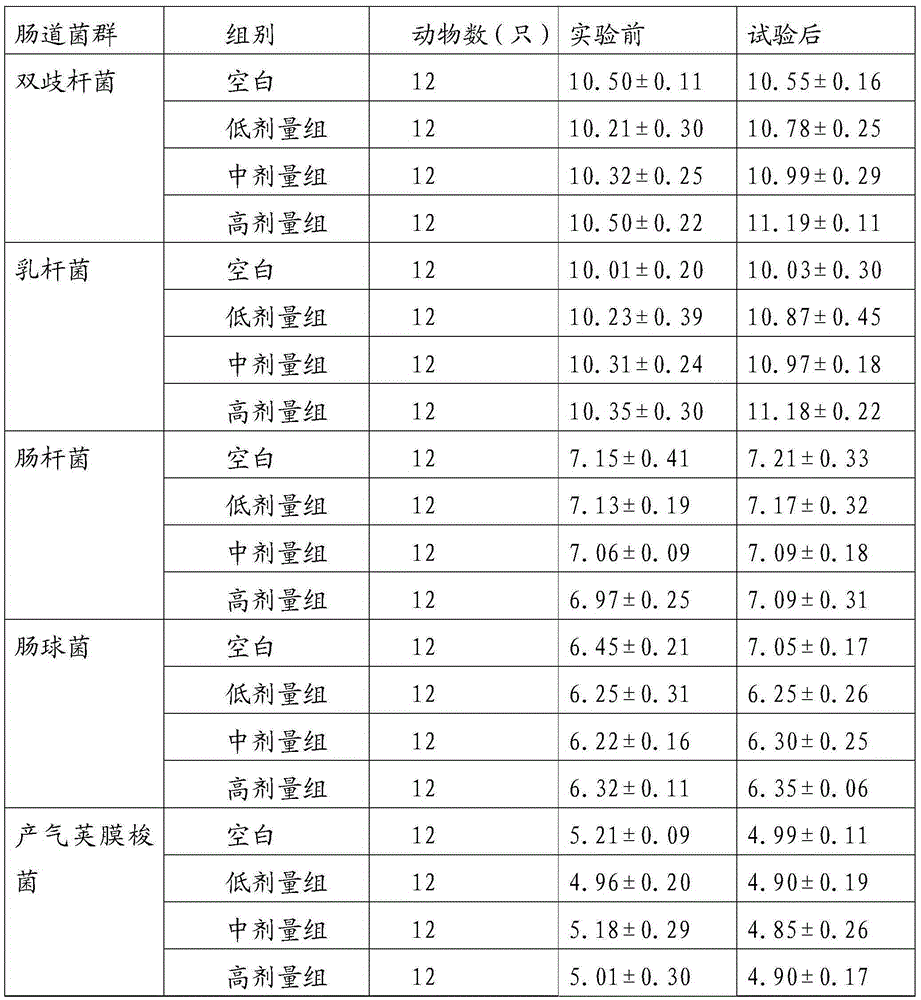

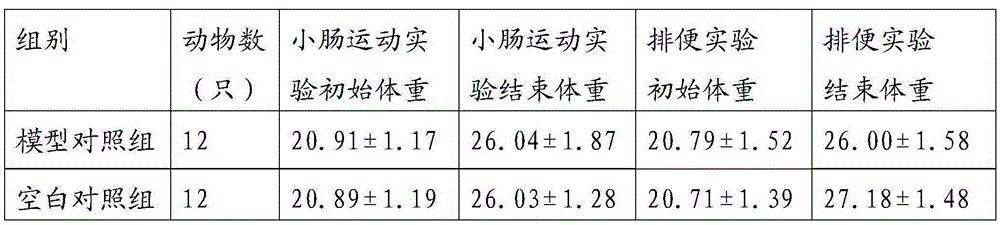

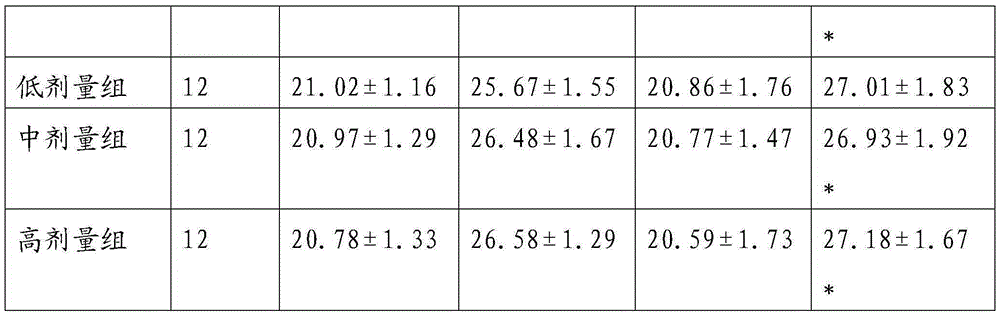

The invention discloses fermented fruit and vegetable composition containing probiotics and traditional Chinese medicine extract and a preparation method of the fermented fruit and vegetable composition. The fermented fruit and vegetable composition comprises fermented fruit and vegetable, fermented or non-fermented traditional Chinese medicine or the traditional Chinese medicine extract, the prebiotics, probiotics and an auxiliary, wherein the prebiotics are formed by one or more oligosaccharides and the probiotics comprise one or more of lactobacillus, bifidobacterium and streptococcus; the fruit and vegetable comprise one or combination of pumpkins, white gourds, kiwi fruits, soybeans, papayas, purple sweet potatoes, carrots, Chinese chestnuts, Chinese yam, maca fruit, pearl barley, Wolfiporia extensa, Angelica sinensis, kudzu vine roots and lotus seeds; the traditional Chinese medicine or the traditional Chinese medicine extract is one or more of Astragalus, olive leaves, grape seeds, ginger, gardenias, saw palmetto, pumpkin seeds, pomegranate seeds, pomegranate bark, raspberries, Cistanche deserticola, black cohosh, red clover or extract thereof. The fermented fruit and vegetable composition is food, a medicine or a health care product with the efficacy of regulating intestinal flora, boosting immunity, improving sleeping function and the like.

Owner:WINERGEN TECH WEIFANG

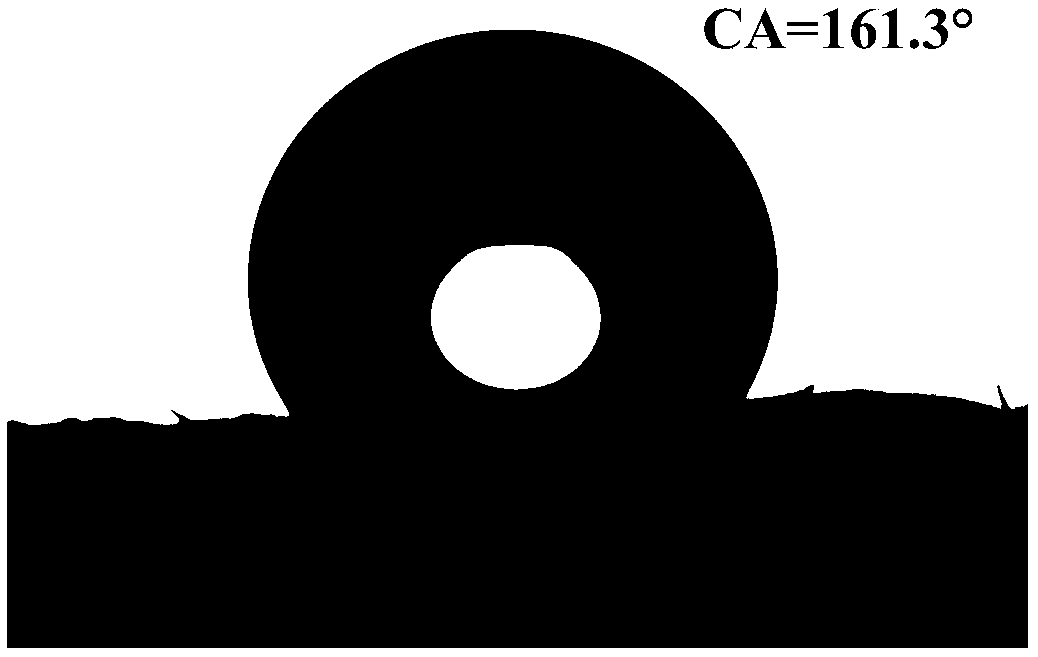

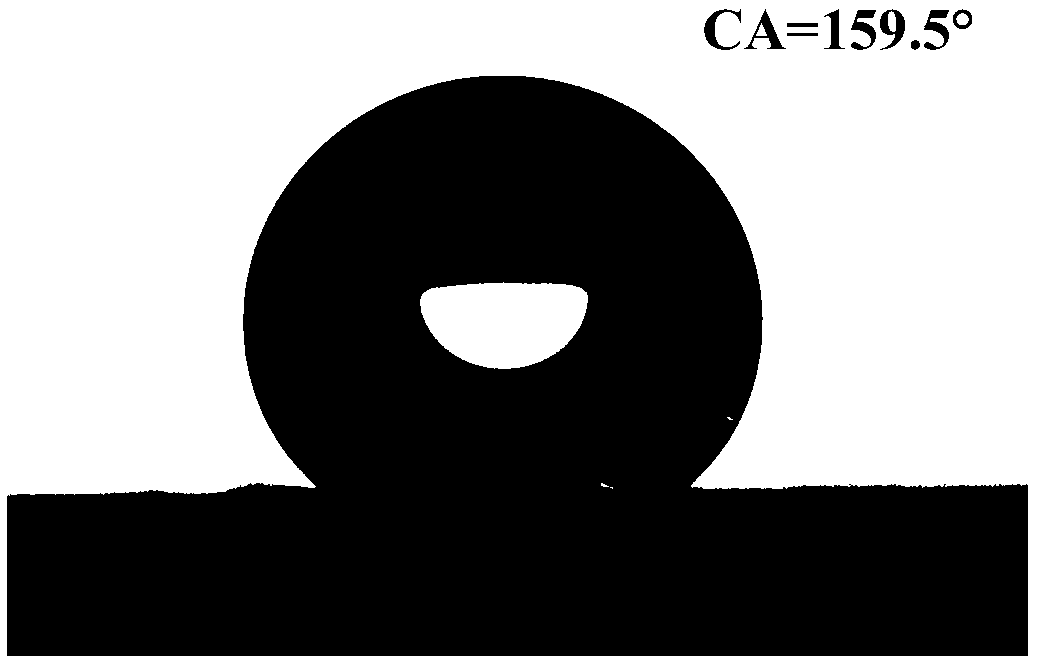

Water-based superhydrophobic coating and preparation method thereof

The invention provides a water-based superhydrophobic coating and a preparation method thereof. The coating is prepared from the following raw materials in percentage by mass: 1-20 percent of hydrophobic resin, 10-90 percent of good solvent of hydrophobic resin, 0.01-1 percent of an additive, 0.1-10 percent of nano-particles and the balance of water, wherein the additive is a curing agent or adhesive resin; the hydrophobic resin is one or more of organic silicon resin, fluorocarbon resin, fluorinated modified epoxy resin and fluorinated modified polyurethane; and the nano-particles are one ormore of fumed silica, nano-titanium dioxide, nano-alumina, fluorine-modified nano-silicon dioxide and alkyl modified nano-silicon dioxide. The water-based superhydrophobic coating is easily availablein raw materials and simple in preparation condition, and can be used for treating various substrates by a simple dip-coating or spraying process so as to obtain a superhydrophobic surface by curing.

Owner:HEBEI UNIV OF TECH

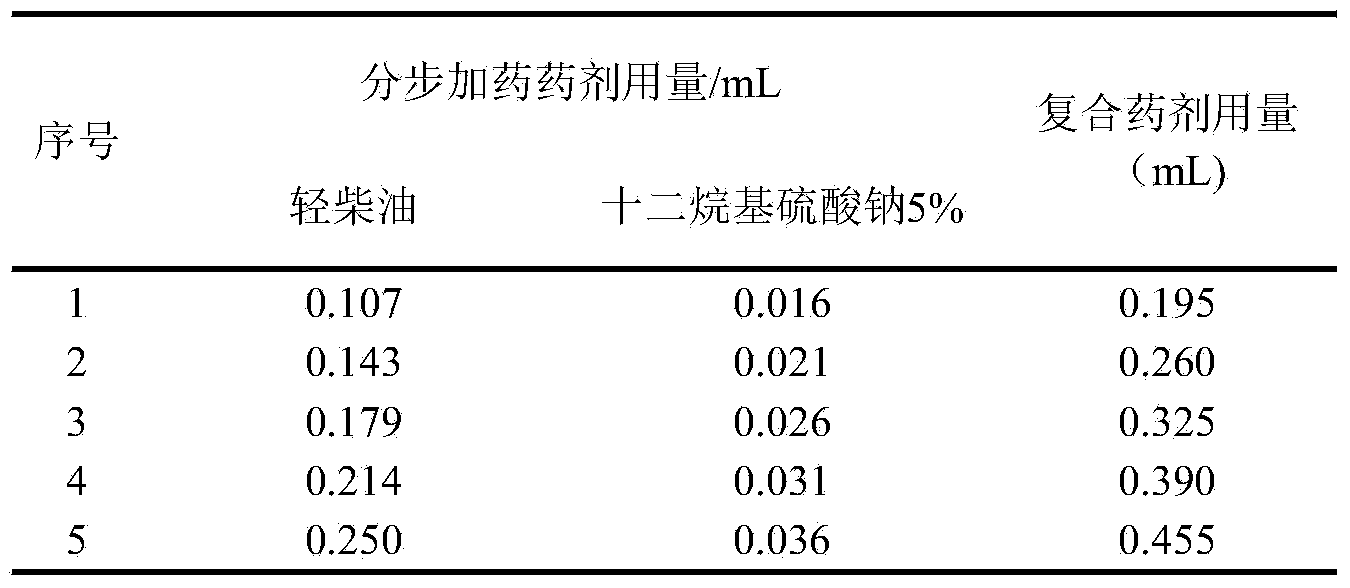

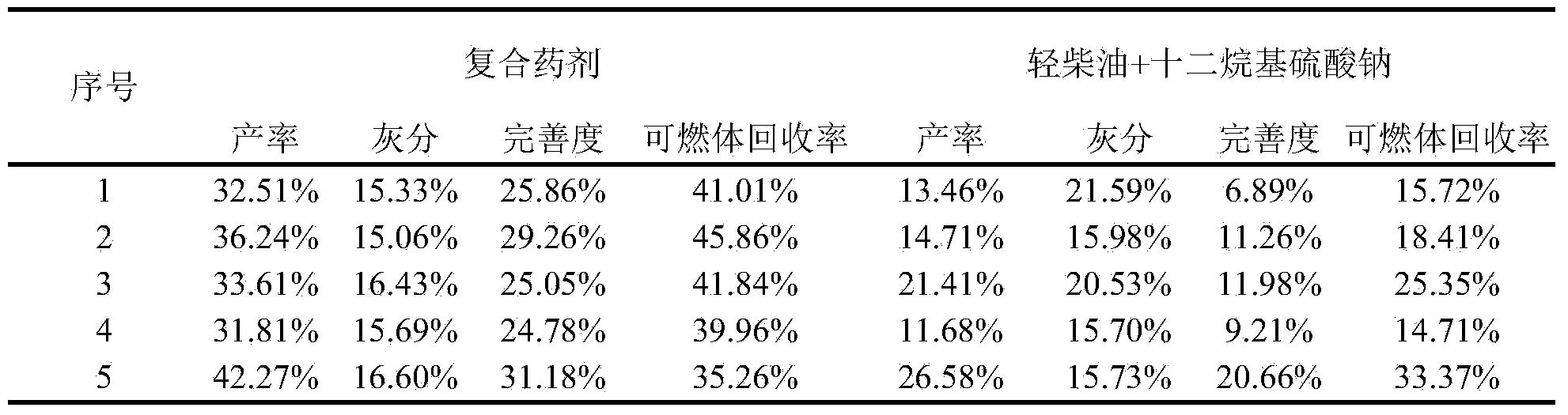

Composite coal-dressing flotation reagent and preparation method thereof

The invention discloses a composite coal-dressing flotation reagent and a preparation method of the composite coal-dressing flotation reagent. The composite coal-dressing flotation reagent is an ivory water-soluble composite coal-dressing flotation reagent which is formed in the mode that light diesel oil, lauryl sodium sulfate, alkyl glycoside, alkylphenol polyoxyethylene ether and water are mixed and subjected to emulsification treatment through a low-temperature emulsification technology. The preparation method of the composite coal-dressing flotation reagent is simple, sources of raw materials are wide, complex operation is avoided, and industrialization can be easily achieved. The composite coal-dressing flotation reagent is used for conducting flotation processing on fine-grained coal slime; compared with a single flotation reagent combination composed of alkyl glycoside and light diesel oil which are added step by step, the composite coal-dressing flotation reagent shows an enhanced coal-dressing flotation effect on fine coal with the granularity smaller than 0.5 mm and overcomes the defect that the reagent is added step by step, the dosage of the reagent is reduced, and the economic benefit is considerable.

Owner:ANHUI UNIV OF SCI & TECH

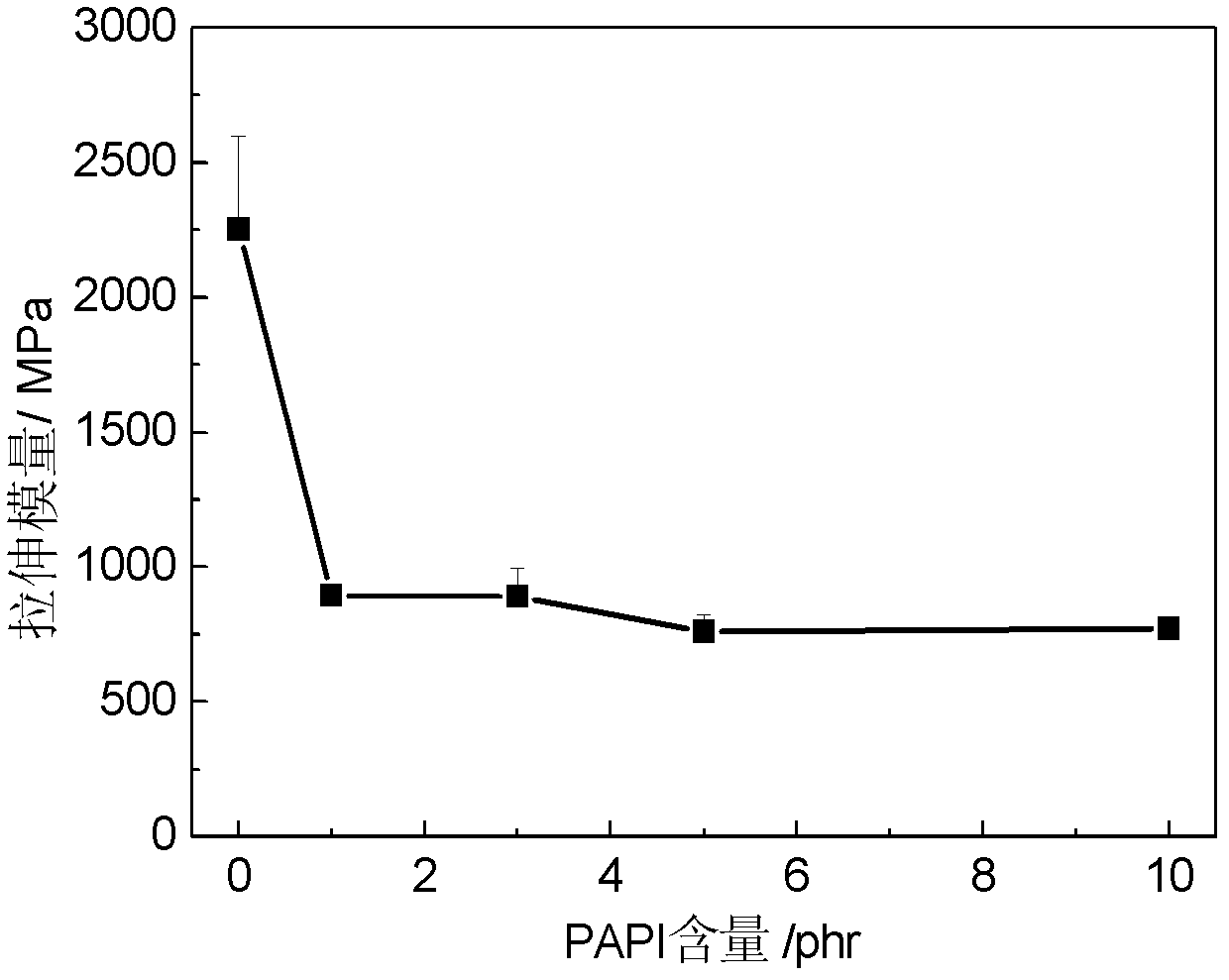

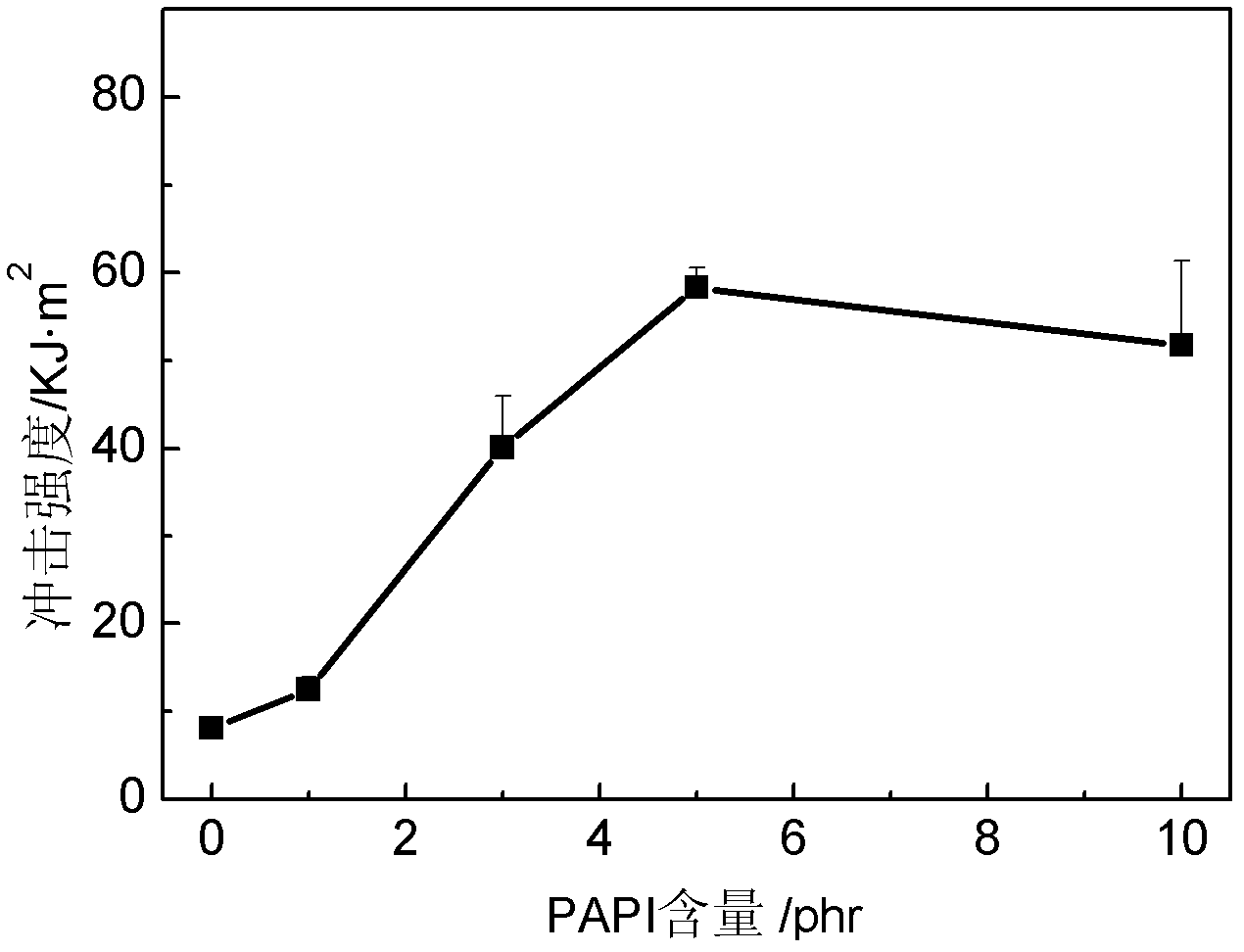

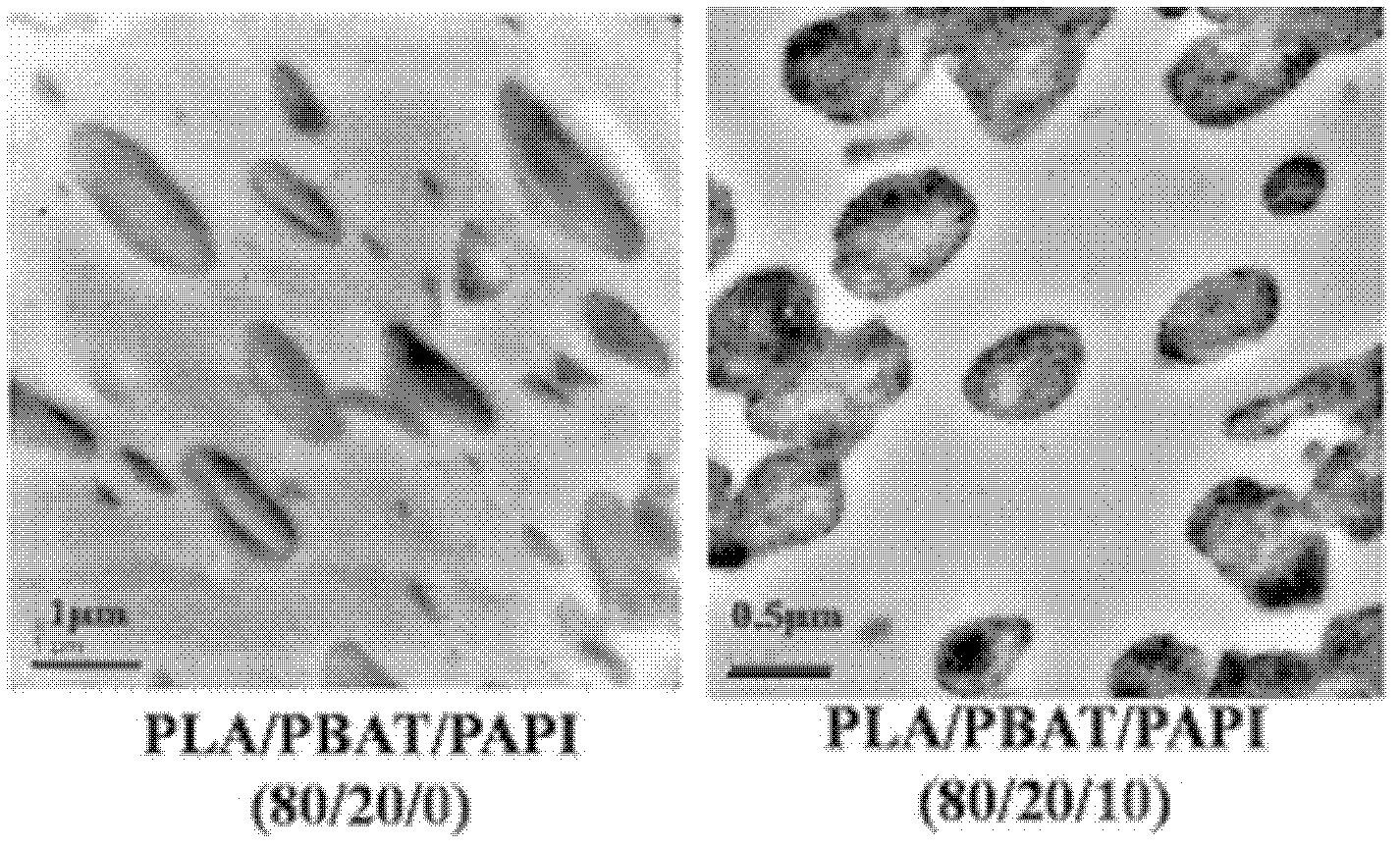

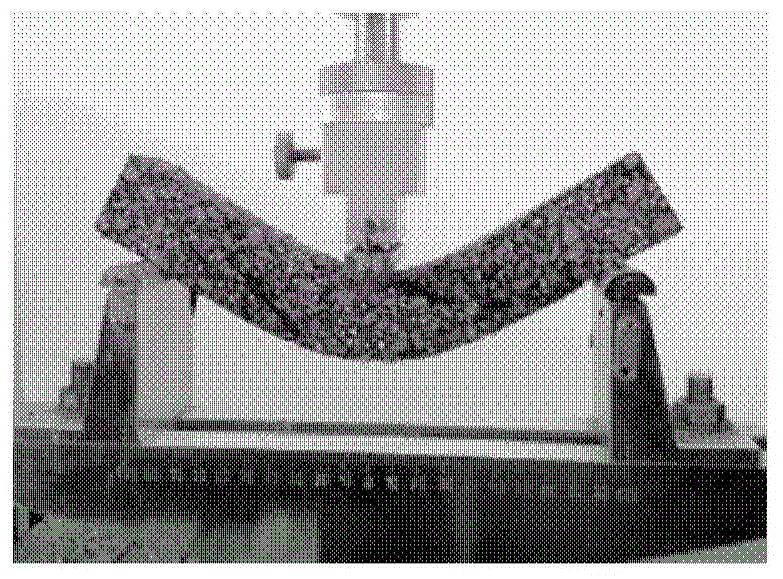

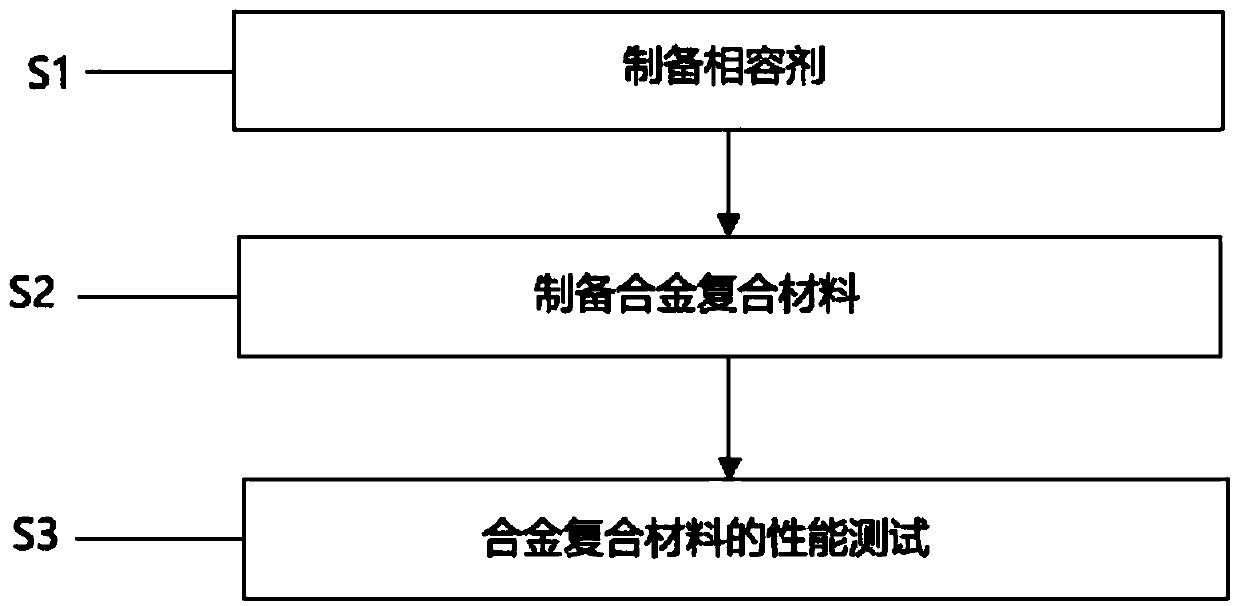

Method for compatibilizing PLA/PBAT alloy

The invention relates to a method for compatibilizing PLA / PBAT alloy. The method comprises the following steps of: after melting the PLA / PBAT alloy, adding a compatilizer into the PLA / PBAT alloy, and blending at 140-220 DEG C for 5-60 min to obtain modified blend, wherein the use amount of the compatilizer is 0.001-90 wt% of the total mass of the PLA / PBAT. Compared with the prior art, the method disclosed by the invention has the advantages of lowering surface tension, reducing dispersed phase size, greatly improving two-phase compatibility and the like.

Owner:SHANGHAI JIAO TONG UNIV

High fracture toughness and elasticity modified asphalt, preparing method and application thereof

Provided is high fracture toughness and elasticity modified asphalt. The needle penetration of the high fracture toughness and elasticity modified asphalt is larger than 301 / 10 mm, the ductility is larger than 40 cm under the temperature of 5 DEG C, and the softening point is larger than 90 DEG C. The high fracture toughness and elasticity modified asphalt comprises, by mass, 70%-85% of matrix asphalt, 5%-20% of thermoplastic elastomer, 2%-5% of reinforcing agent, 1%-5% of compatilizer, 5%-20% of a softening agent, 0.01%-0.1% of a dispersing agent, 0.2%-0.5% of a cross-linking agent and 0.5%-2% of viscosity reducer. According to the modified asphalt, the mixing amount of a modifying agent is high, the stability is good, the high and low temperature performances are good, using for construction is convenient, curl pavements and other functional pavements can be prepared, and the high fracture toughness and elasticity modified asphalt is used for paving of roads and bridge faces.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

Multi-crosslinking modified nuclear-shell structure room-temperature self-crosslinking acrylic emulsion and preparation method thereof

The invention discloses multi-crosslinking modified nuclear-shell structure room-temperature self-crosslinking acrylic emulsion and a preparation method thereof, and belongs to the field of polymer synthesis. The acrylic emulsion is synthesized by a pre-emulsification-semi-continuous seed core-shell polymerization process, the soft and hard monomer ratio of a nuclear layer and a shell layer is controlled, crosslinking monomers such as diacetone acrylamide, hydroxymethyl acrylamide and acetoxyethyl methacrylate are introduced into the shell layer, and the multi-crosslinking modified acrylic emulsion with a nuclear-shell structure is prepared. The acrylic emulsion has excellent storage and transportation stability and a wide application prospect and can be subjected to multi-crosslinking reaction and cured into a film at room temperature, the water resistance and the mechanical performance of the acrylic film is remarkably improved, and the adhesion of the film for metal, glass and plastic base materials is improved.

Owner:郑州中科新兴产业技术研究院 +1

Biodegradable polymer material compatibilized and blended by lignocellulose and preparation method thereof

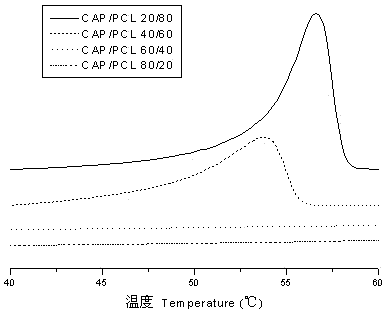

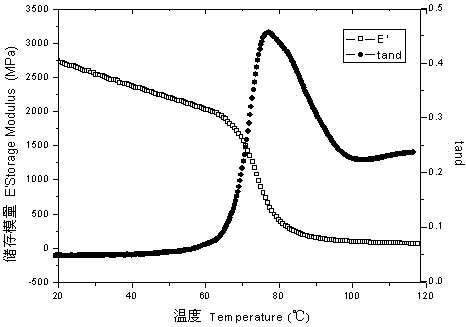

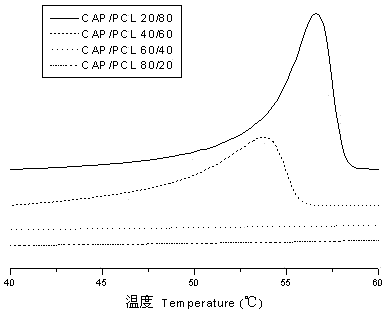

The invention discloses a biodegradable polymer material compatibilized and blended by lignocellulose and a preparation method thereof. The biodegradable polymer material is composed of a resin mixture and a compatibilizer. The resin mixture is composed of resin and cellulose acetate or cellulose acetate propionate which is prepared from cellulose of poplar wood pulp. The resin is selected from any one of polycaprolactone, polylactic acid and polyhydroxybutyrate. The compatibilizer is a block copolymer of polycaprolactone-acid anhydride compound and the use amount of the compatibilizer is 2-30% of the total mass of the resin mixture. The preparation method provided by the invention comprises the following steps of: mixing celluosic resins to obtain the resin mixture; then compulsively feeding after adding the resin mixture and the compatibilizer into a feed bin of a double-screw extruder; cooling the extrudate by air and then dicing the extrudate into particles to obtain resin particles. The biodegradable polymer material and the preparation method provided by the invention have advantages of environmental friendliness, low cost, good combination property, stable product performance and higher promotion value.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Mochi bread premix powder with good freeze thawing stability, mochi bread and production thereof

InactiveCN104012591AIncrease productionAvoid odorDough treatmentBakery productsMaltodextrinRice flour

Owner:GUANGZHOU FOOD IND RES INST

Camellia oil micro-nano emulsion and preparation method thereof

ActiveCN109481319AGood skin carePlay a protective role in repairingCosmetic preparationsToilet preparationsMicro nanoAntioxidant

The invention relates to the field of skin care cosmetics, and provides a camellia oil micro-nano emulsion and a preparation method thereof to solve the problems that the existing camellia oil is sticky in appearance, which is inconvenient for daily skin care; the camellia oil skin care product prepared by the traditional emulsification method is bad in sensory effects and large in particle size,as a result, the dispersion performance in a medium is poor, and the use is not convenient, thus, the development and application of camellia oil are limited in the field of cosmetics. The camellia oil micro-nano emulsion is prepared from the following components by weight percentage: 35-50 percent of camellia oil, 2-8 percent of phospholipids, 0.1-0.3 percent of antioxidant, 2-10 percent of waterand the balance of glycerin. By selecting natural and safe raw materials and adopting proper proportion, the camellia oil micro-nano emulsion prepared by the invention is small in micro-nano emulsionparticle size, thus, the camellia oil is easier to penetrate skin so as to reach better absorbency; the load of the camellia oil is large so as to reach a better moisturizing effect; and moreover, the appearance of the product is transparent or semi-transparent, bringing customers more aesthetic experience.

Owner:HANGZHOU QIANDAOHU TIANXIN CO LTD

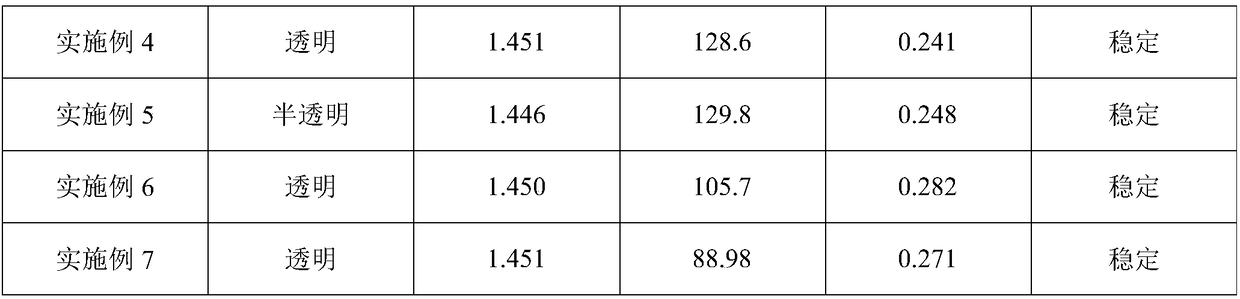

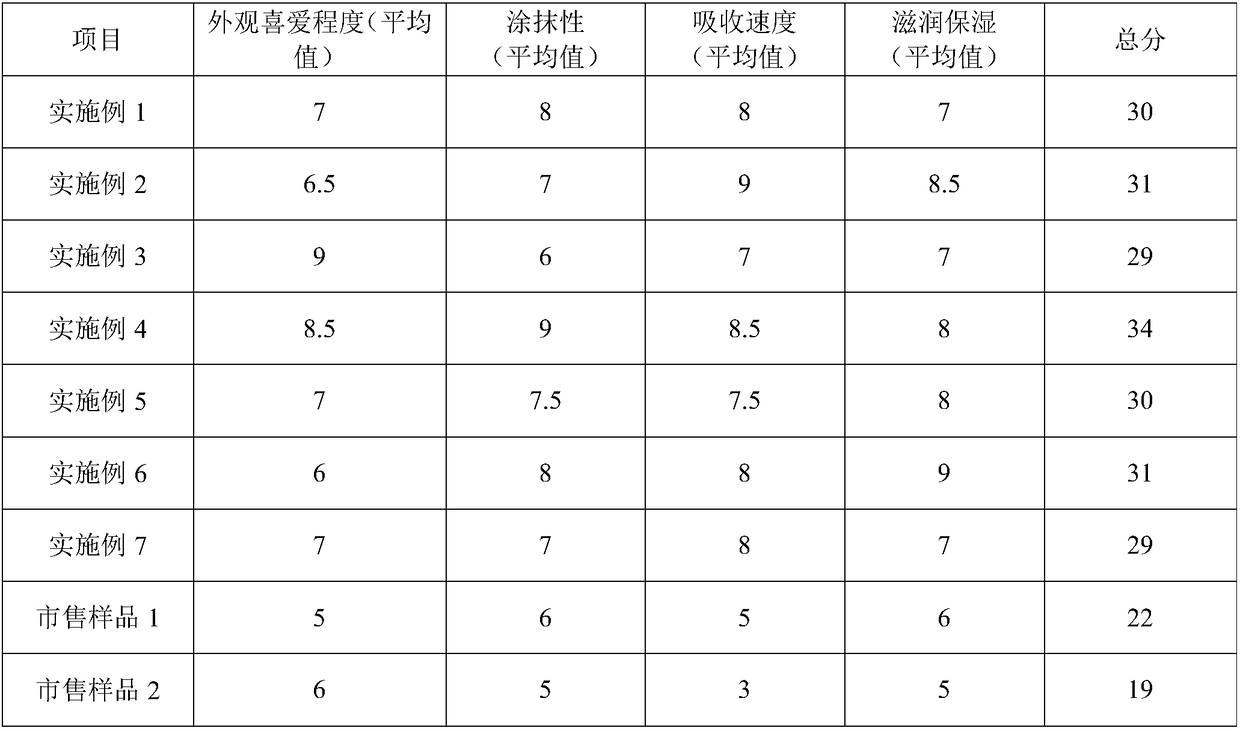

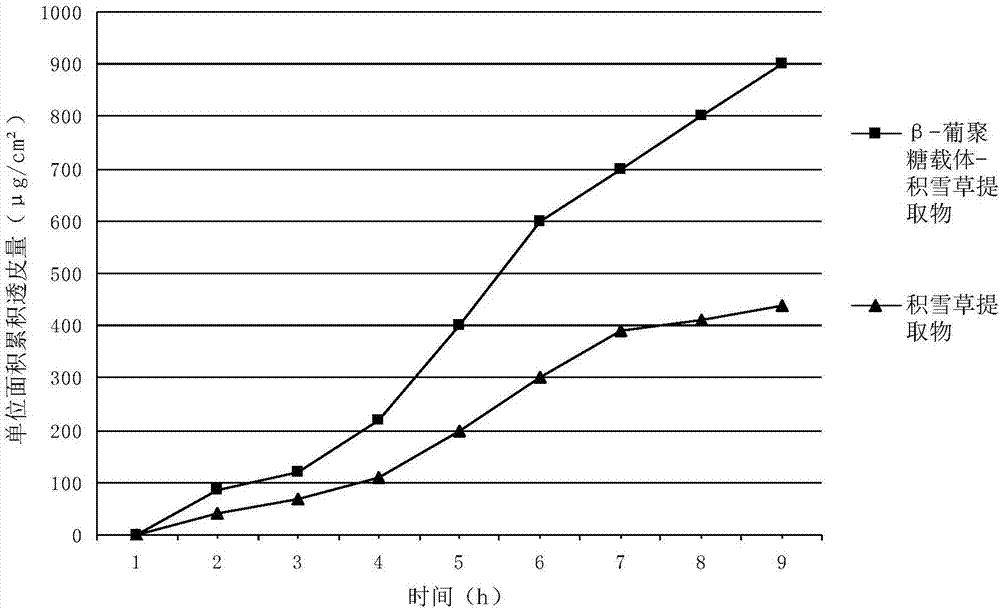

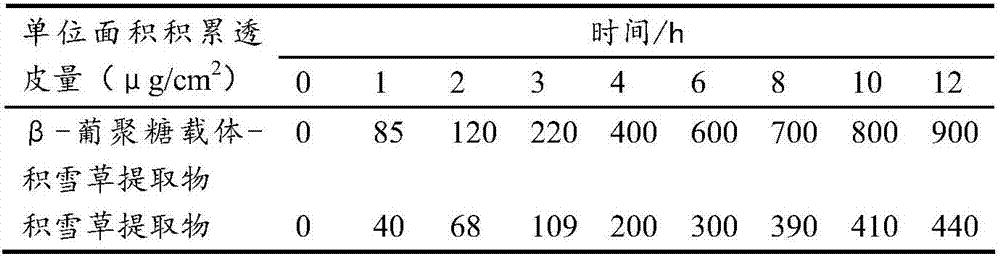

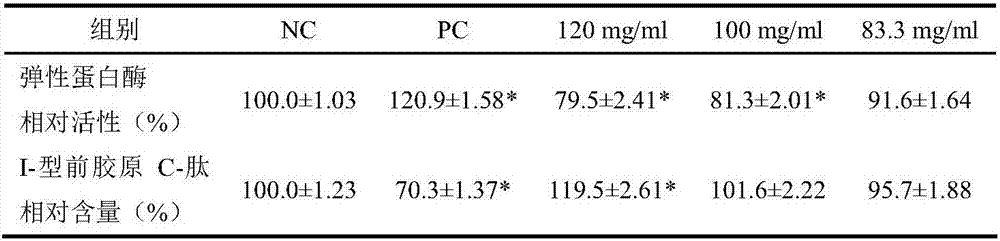

Stretch mark cream

ActiveCN106963677APlay an emulsifying rolePromote transdermal absorptionCosmetic preparationsToilet preparationsSkin repairSkin striae

The invention discloses a stretch mark cream, which is prepared from, by weight percent, 50-70% of beta- glucosan, 3-5% of glycerinum, 2-5% of simmondsia chinensis seed oil, 2-5% of Vitamin E oil, 2-5% of avocado tree butter, 3-7% of olive oil, 1-3% of centella extractive, 0.2-1% of notoginsenoside, and 0.1-1% of dipotassium glycyrrhizinate. The stretch mark cream has the beneficial effect that every effect4ive component can be rapidly penetrated to a skin corium layer through reasonable formula combination to accelerate the skin repair, thus the skin collagenous fiber and elasticity fiber for forming the stretch mark; meanwhile, the pigment is diluted, and the skin moistening function is enhanced; the cream has good removal effect for the formed stretch mark, in particular to the stretch mark for over 3 years.

Owner:NINGBO XINUOYA MARINE BIOTECH CO LTD

Method for preparing goose sausages by using obsolete old gooses

The invention discloses a method for preparing goose sausages by using obsolete old gooses. The method is characterized by comprising the following steps of: preparing a goose raw material; mixing the goose raw material, pig backfat and pig lean meat in a weight ratio of 100:37:50, adding composite phosphate in an amount which is 0.3 percent of the weight of goose, and stirring; adding a papain solution in an amount which is 1.5 percent of the weight of meat paste into the meat paste; mixing table salt, sodium nitrite, wiener spice, soy protein, lactalbumin, potato starch, carrageenan, composite phosphate and a monascus pigment in a weight ratio of 4:0.02:1.3:1.3:4:4:12:1:0.4, dissolving in water, and adding into the meat paste for salting; and filling sausages, cooking and drying to obtain the goose sausages prepared from the obsolete old gooses. The invention has the advantages that: the tender degree and water retention of products are improved, the texture and color of the products are improved, and the goose sausages have good mouthfeel, no bilgy odor, unique flavor and high nutritional value.

Owner:黑龙江鹅香久食品有限公司

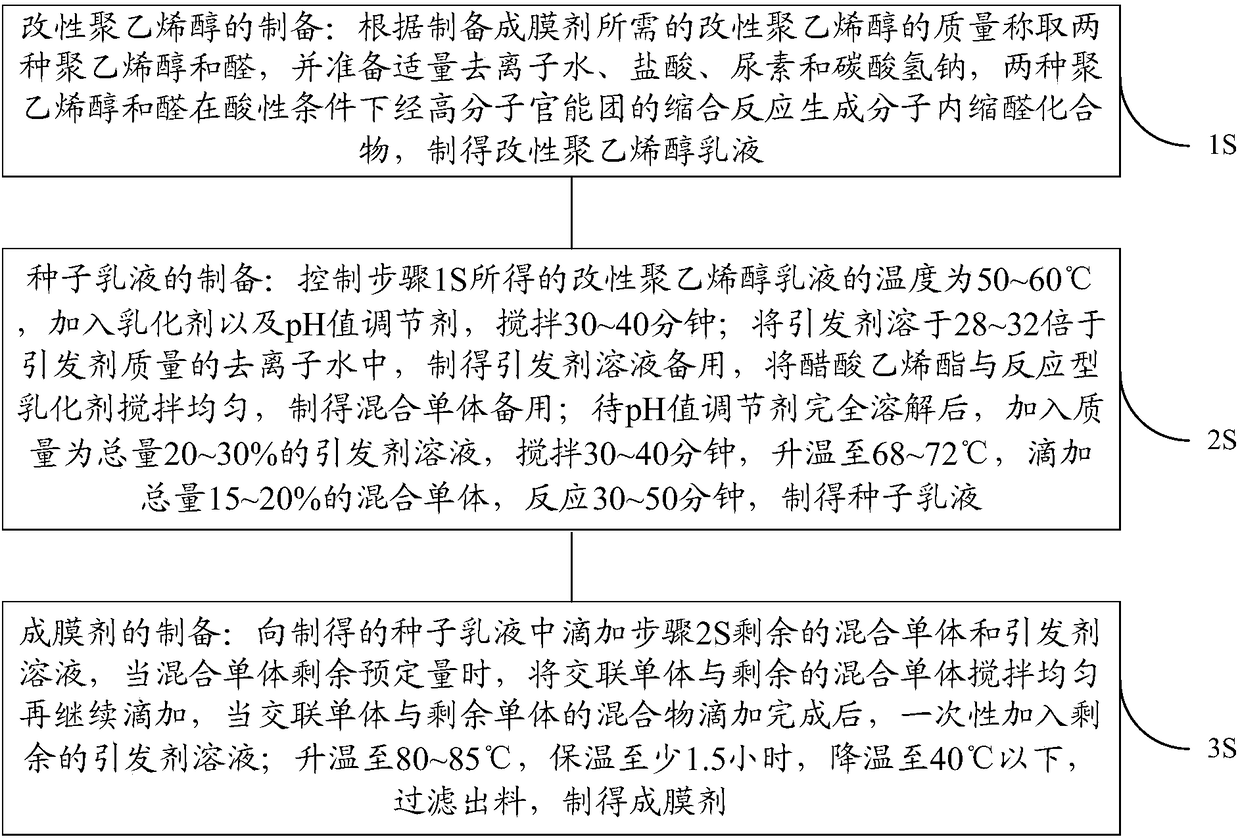

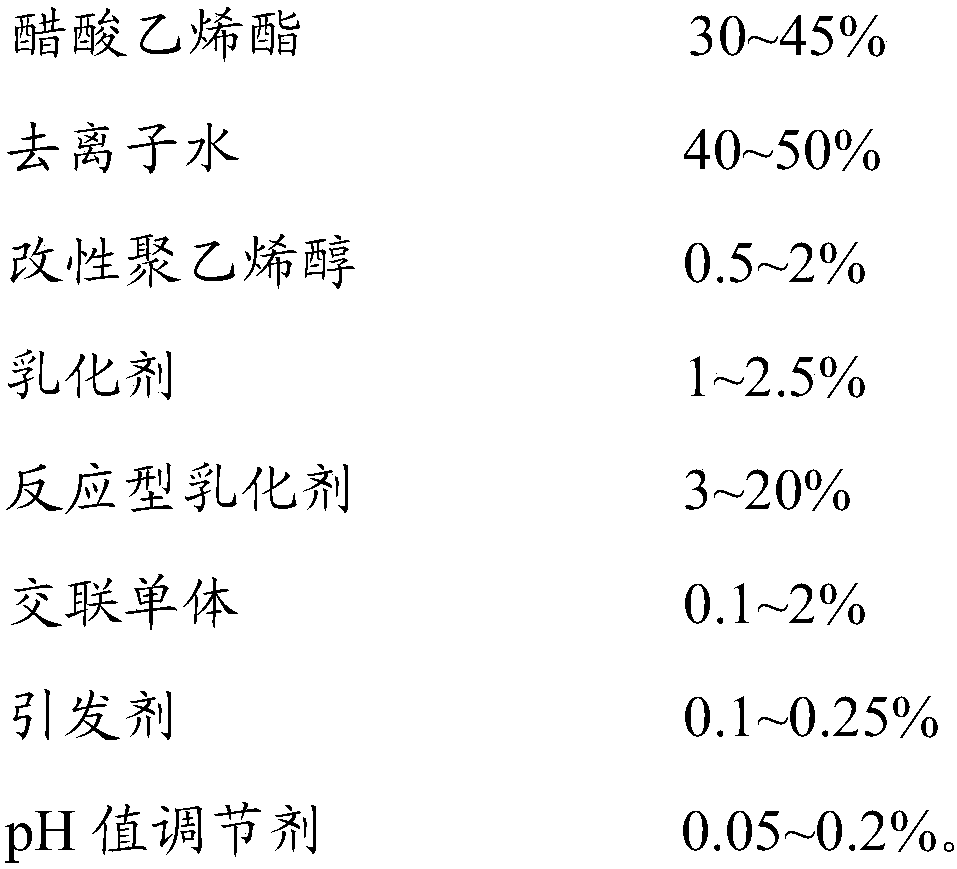

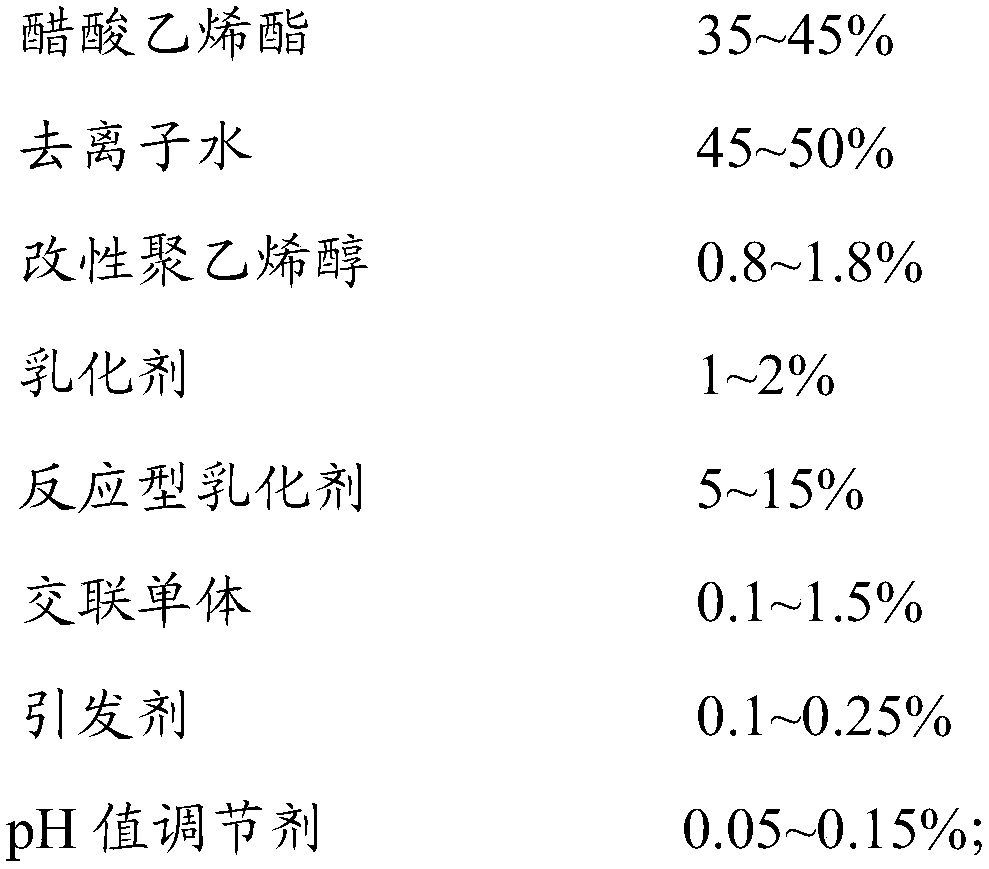

Self-crosslinking polyvinyl acetate film-forming agent, preparation method and uses thereof

The invention provides a self-crosslinking polyvinyl acetate film-forming agent, wherein the raw materials comprise vinyl acetate, deionized water, modified polyvinyl alcohol, an emulsifier, a reactive emulsifier, a cross-linking monomer, an initiator and a pH value adjuster, and the cross-linking monomer is an amide compound. According to the present invention, through the mutual cooperation of the components, the prepared film-forming agent has characteristics of strong precursor bundling property, excellent high-temperature performance, high stiffness, good self-crosslinking property, goodsolvent resistance and the like. The invention further provides a preparation method and uses of the self-crosslinking polyvinyl acetate film-forming agent.

Owner:JUSHI GRP CO

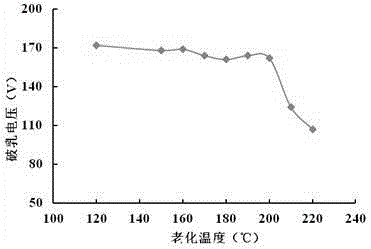

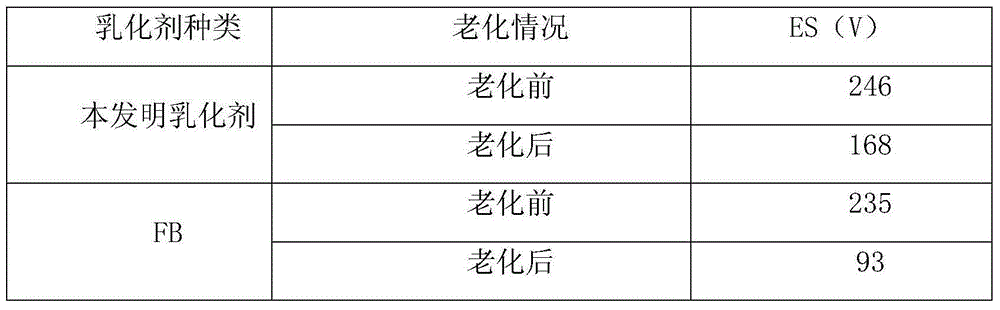

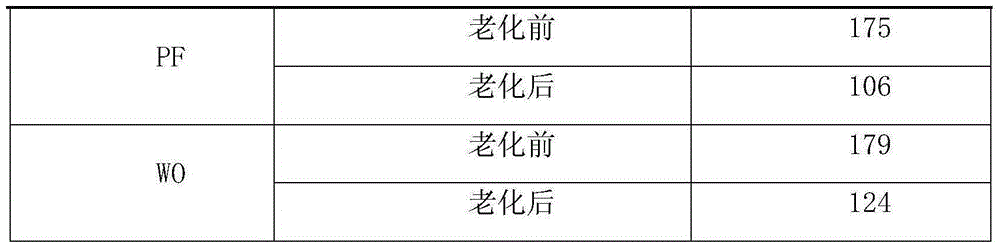

Emulsifier for high-temperature-resisting oil-based drilling liquid and preparation method thereof

InactiveCN105154036AHigh temperature resistanceReduce interfacial tensionDrilling compositionHigh intensityOil water

The invention discloses an emulsifier for high-temperature-resisting oil-based drilling liquid. The emulsifier consists of the following raw materials in parts by weight: 12 to 30 parts of oleic acid; 1 to 10 parts of oleic diethanolamide; 1 to 10 parts of sodium fatty alcohol polyoxyethylene ether carboxylate. The preparation method comprises the following steps: measuring raw materials, mixing and stirring the oleic acid and oleic diethanolamide in a stirrer for 10 to 20 minutes, adding the sodium fatty alcohol polyoxyethylene ether carboxylate, and uniformly stirring. The emulsifier is high in temperature resistance, can resist the temperature of 200 DEG C, and is suitable for the drilling liquid in various oil-water ratios; the tension on an oil-water interface can be greatly reduced; a high-strength interface film can be formed, and an emulsification function can be realized. The emulsifier is simple in components, wide in source and low in cost. The preparation method is simple to operate, convenient to prepare and suitable for the industrialized mass production.

Owner:SOUTHWEST PETROLEUM UNIV

High-content alpha-linolenic acid microcapsule and manufacturing method thereof

ActiveCN103461988AExpand the scope of applicationSolve the shortcomings of easy oxidationFood shapingFood preparationOCTENYLSUCCINIC ACIDMass content

The invention discloses a high-content alpha-linolenic acid microcapsule and a manufacturing method thereof. The microcapsule comprises a core material (an alpha-linolenic acid product with mass content of alpha-linolenic acid being no less than 80%), a wall material (starch sodium octenylsuccinate) and an emulsifier (flaxseed gum), wherein a weight ratio of the core material to the emulsifier is 100-500: 1, and a weight ratio of the core material to the wall material is 1-1.2: 0.8-1. The manufacturing method comprises the following steps: dissolving a part by weight of the emulsifier in water to prepare a solution with a concentration of 0.1 to 1.0% and then adding 100 to 500 parts by weight of the alpha-linolenic acid product into the solution; then dissolving starch sodium octenylsuccinate into water to prepare a solution with a concentration of 13 to 40%, wherein a weight ratio of starch sodium octenylsuccinate to the alpha-linolenic acid product is 0.8-1: 1-1.2; and finally mixing the two prepared solutions and carrying out emulsification, homogenization and spray drying so as to obtain alpha-linolenic acid microcapsule powder, wherein alpha-linolenic acid has high content, is hard to oxidize and has good fluidity, total fatty acids (W / W) is no less than 50%, moisture is no more than 1.2%, surface oil is no more than 2%, and alpha-linolenic acid is no less than 400 mg / g.

Owner:河北欣奇典生物科技有限公司

Manufacturing method of instant beany-flavor-free cold drink soybean powder

ActiveCN102669293AHigh nutritional valueBright whiteMilk substitutesFood scienceSoya flourCold drinks

The invention provides a manufacturing method of instant beany-flavor-free cold drink soybean powder. The manufacturing method comprises the following steps of: (1) selecting materials: taking soybean separated proteins and soybeans as raw materials; (2) carrying out two times of deodorization: a, carrying out the first time of the deodorization: roughly grinding with hot water at 80-85 DEG C; adjusting PH (Potential of Hydrogen) to 6.8-7.0 in a roughly grinding process; and carrying out the second time of the deodorization: after separating slurry and residues, adding 0.15-0.2% of calcium stearoyl lactylate before sterilizing and deodorizing. The manufacturing method disclosed by the invention prepares the soybean powder with the character which is similar with milk powder; the soybean powder does not have a beany flavor and the color of the product is milk white; and the manufacturing method of the instant beany-flavor-free cold drink soybean powder widens the application range of the soybean powder in high-end cold drink raw material powder, improves the quality and reduces the cost.

Owner:HEILONGJIANG BEIDAHUANG GREEN HEALTH FOOD

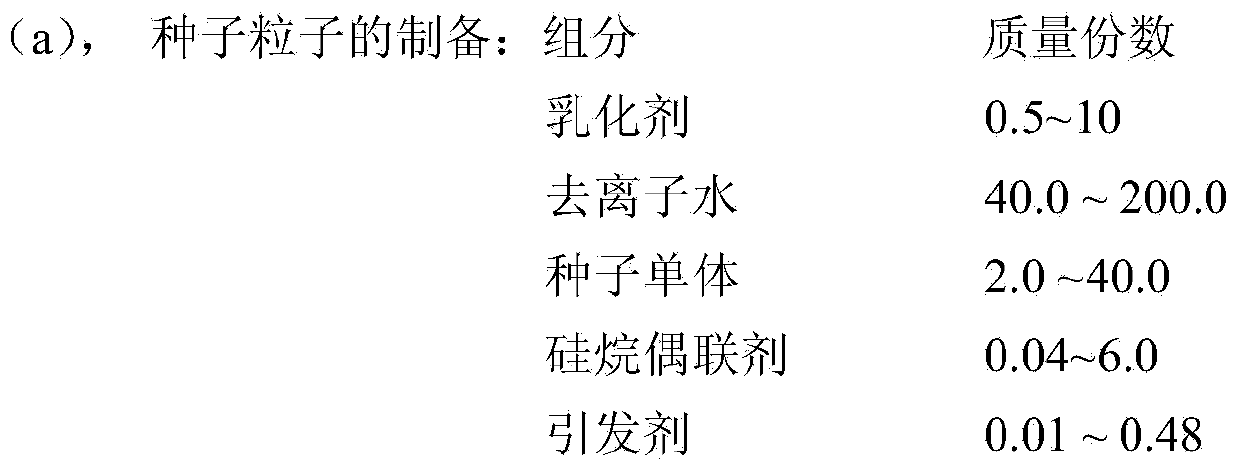

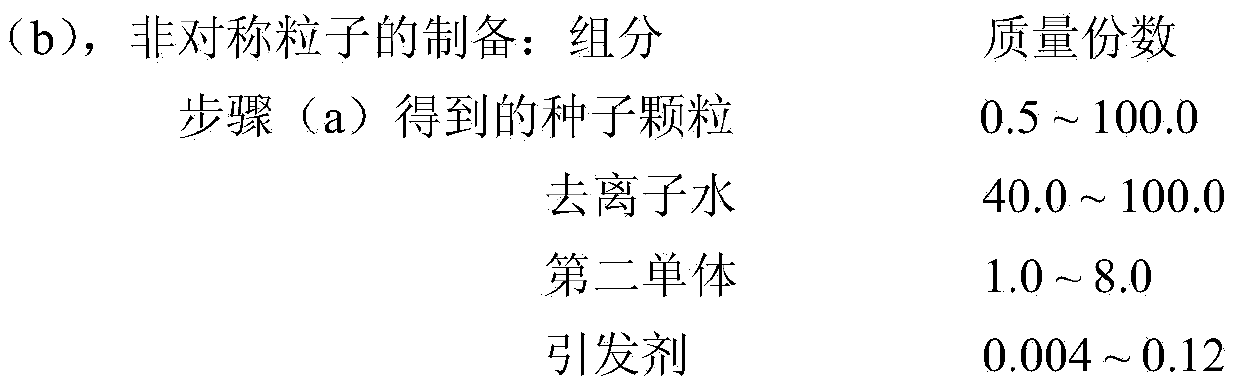

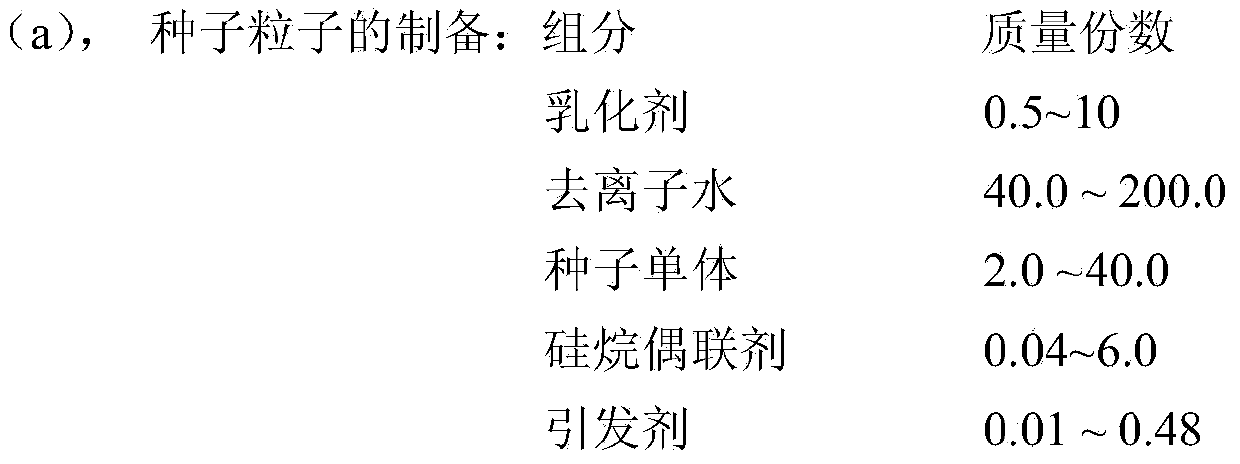

Preparation method of anisotropic particles with variable morphology

The invention relates to a preparation method of anisotropic particles with variable morphology. The method comprises the following steps: firstly utilizing silanol hydrophilic groups produced by hydrolysis of a silane coupling agent to prepare a series of seeds with different hydrophilicities, then enabling the seeds to be swollen by monomers incompatible to the hydrophilic groups, and controlling the phase separation degree according to different phase separation degrees of polymers, which are induced by different interfacial tensions and incompatible to the hydrophilic groups so as to obtain the composite particles with the variable morphology. The composite particles contain organic-inorganic-organic phase non-spherical composite particles, which have an important significance for developing novel multi-component materials. The composite particles prepared by the preparation method disclosed by the invention are amphipathic, and can be used as compatibilizers, emulsifiers and the like for modifying mixtures of the incompatible polymers. The synthesis process is simple and easy to operate, clean, environment-friendly and easy to realize large-scale production; furthermore, the preparation method has universality and is suitable for other polymer systems which are mutually incompatible.

Owner:天津知顺科技有限公司

Recoverable paper cup emulsion and preparation method thereof

InactiveCN113062143AReduce surface tensionImprove waterproof performanceWater-repelling agents additionPaper coatingPolymer scienceAdhesive

The invention provides a recoverable paper cup emulsion and a preparation method and application thereof, and the emulsion comprises the following raw materials by mass: 60-70% of soft water, 5-8% of methyl methacrylate, 3-6% of ethyl methacrylate, 2-5% of methacrylic acid, 3-8% of styrene, 1-5% of a reactive emulsifier, 0.3-2% of an initiator, 5-10% of an ethylene-acrylic acid copolymer, 0.5-3% of a dispersant and 0.2-1% of an antifoaming agent. The reactive emulsifier is selected from sodium acrylamido isopropyl sulfonate and / or sodium allylsuccinic acid alkyl ester sulfonate. The emulsion provided by the invention has excellent waterproof performance. The polymerization product is mixed with the ethylene-acrylic acid copolymer, due to the existence of carboxyl groups in the EAA emulsion and the action of hydrogen bonds, the adhesive force of the coating on the surface of paper is improved, meanwhile, the coating has good heat sealing strength at a certain temperature, and lap adhesive does not need to be coated when a paper cup is made.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

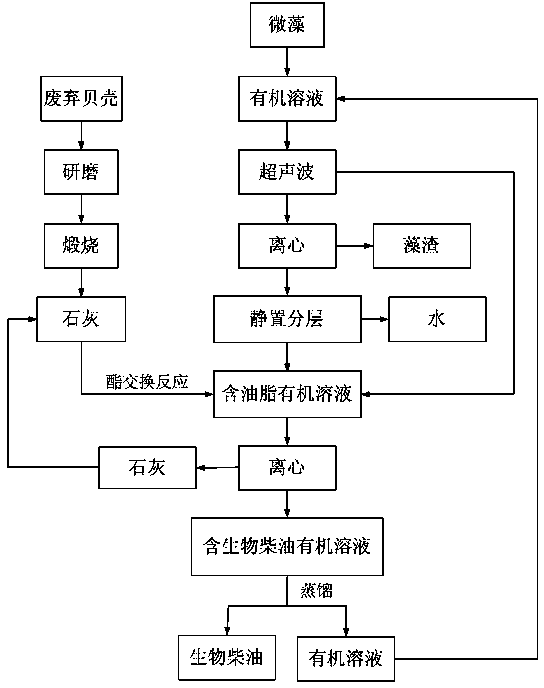

Method for producing wet microalgae biodiesel through calcining shells into lime under assistance of ultrasonic wave

InactiveCN104357213AHigh extraction rateAdd lessFatty acid esterificationFatty acids production/refiningUltrasonic assistedTransesterification

The invention discloses a method for producing wet microalgae biodiesel through calcining shells into lime under the assistance of ultrasonic wave. The method comprises the following steps: taking oily microalgae as a raw material; taking lime powder as a catalyst, adding the microalgae into an organic solution, cracking under the assistance of ultrasonic wave and centrifuging to obtain an greasy organic solution; adding the lime into the greasy organic solution, carrying out emulsification under the assistance of ultrasonic wave and carrying out transesterification; recycling the lime under the centrifugal action; distilling the organic solution containing biodiesel to obtain the biodiesel and recycling the organic solution. The wet microalgae biodiesel production method has the advantages that on one hand, the shell calcined lime is taken as the catalyst to realize the waste resource utilization, and meanwhile, as the lime can be recycled, and the raw material is the wet microalgae, the energy consumption required by drying is eliminated; on the other hand, ultrasonic waves not only play roles in damaging cells at the oil extraction stage and improving the oil extraction rate, but also plays an emulsifying role at the transesterification stage, so that the adding amount of the organic solution and the catalyst is reduced.

Owner:SOUTH CHINA UNIV OF TECH

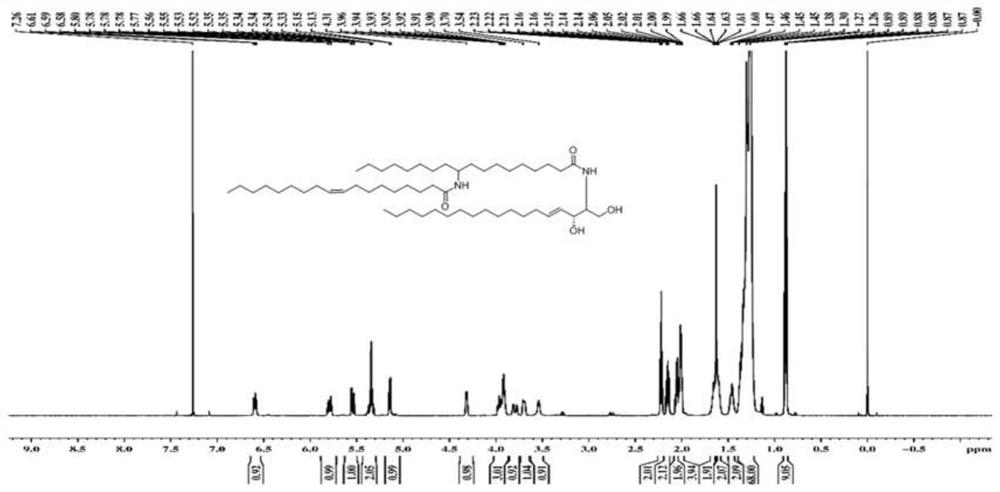

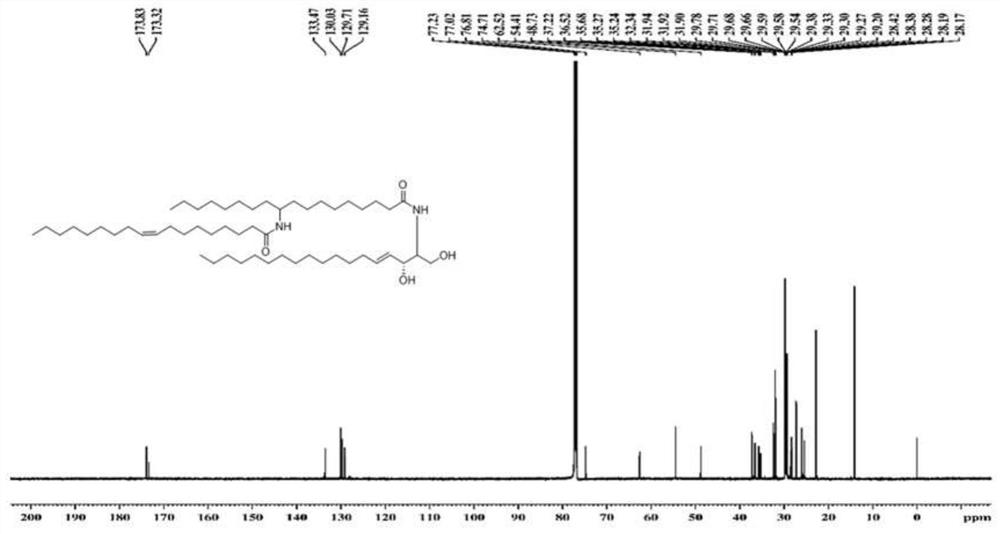

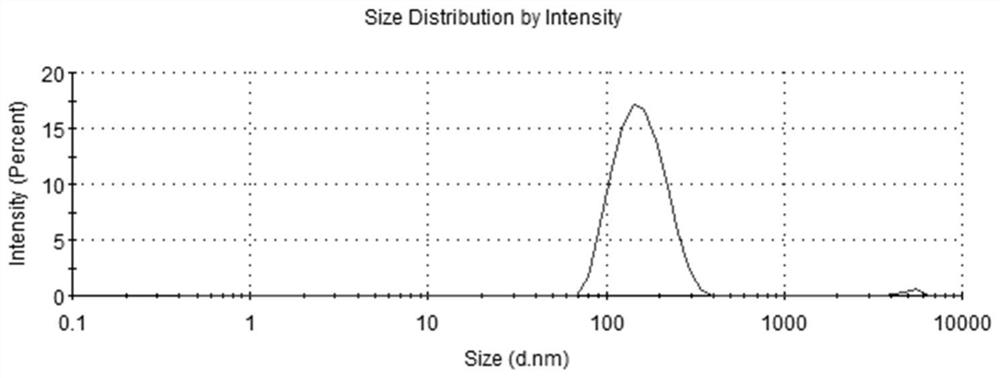

Ceramide compound as well as cationic liposome, preparation method and application thereof

ActiveCN113121381AImprove stabilityIncrease fat solubilityOrganic compound preparationCarboxylic acid amides preparationLiposomeGene carrier

The invention discloses a ceramide compound as well as a cationic liposome, a preparation method and application thereof. The invention provides a ceramide compound with a structure as shown in a formula I. The ceramide compound has the advantages of higher stability and fat solubility and capability of better passing through a skin cuticle. The cationic liposome based on the compound has the advantages of good homogeneity, stable and reliable quality, simple and convenient preparation process, capability of efficiently carrying and delivering nucleic acid, excellent transdermal performance and the like. Compared with a commercialized gene transfection reagent liposome 2000, the cationic liposome based on the ceramide compound has obviously low cytotoxicity and obviously improved gene transfection efficiency, and compared with a traditional liposome, the cationic liposome based on the ceramide compound can improve the endocytosis efficiency of a drug, has more excellent transdermal efficiency, and can be used as a novel lipid gene carrier functional reagent in transfection of nucleic acid drugs.

Owner:ZHEJIANG UNIV

Lubricant for forming stainless steel inner liner

The invention discloses a lubricant for forming a stainless steel inner liner. The lubricant is prepared from, by mass, 3-7 parts of sulfurized olefin, 10-15 parts of sulfurized fatty acid ester, 3-7 parts of overbased calcium sulphonate, 11-14 parts of emulsifier and the balance chlorinated paraffin, wherein the emulsifier is prepared from, by mass, 6-8 parts of fatty alcohol-polyoxyethylene ether and 5-7 parts of petroleum sodium sulfonate, wherein the sulfurized fatty acid ester is used as an anti-wear agent at an extreme pressure, the chlorinated paraffin has excellent lubricating and extreme pressure resistance efficacies for stainless steel machining in a low-temperature area, the overbased calcium sulphonate plays a coordinating role in a system, and the fatty alcohol-polyoxyethylene ether and the petroleum sodium sulfonate contribute to emulsification in the system.

Owner:上海希勒化学有限公司

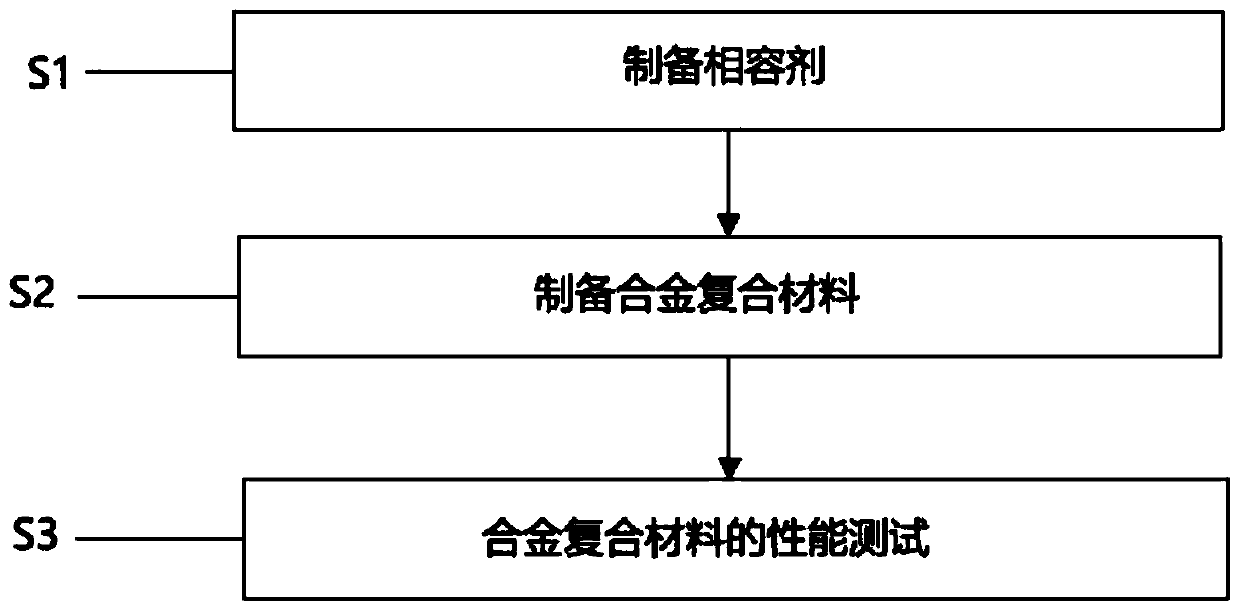

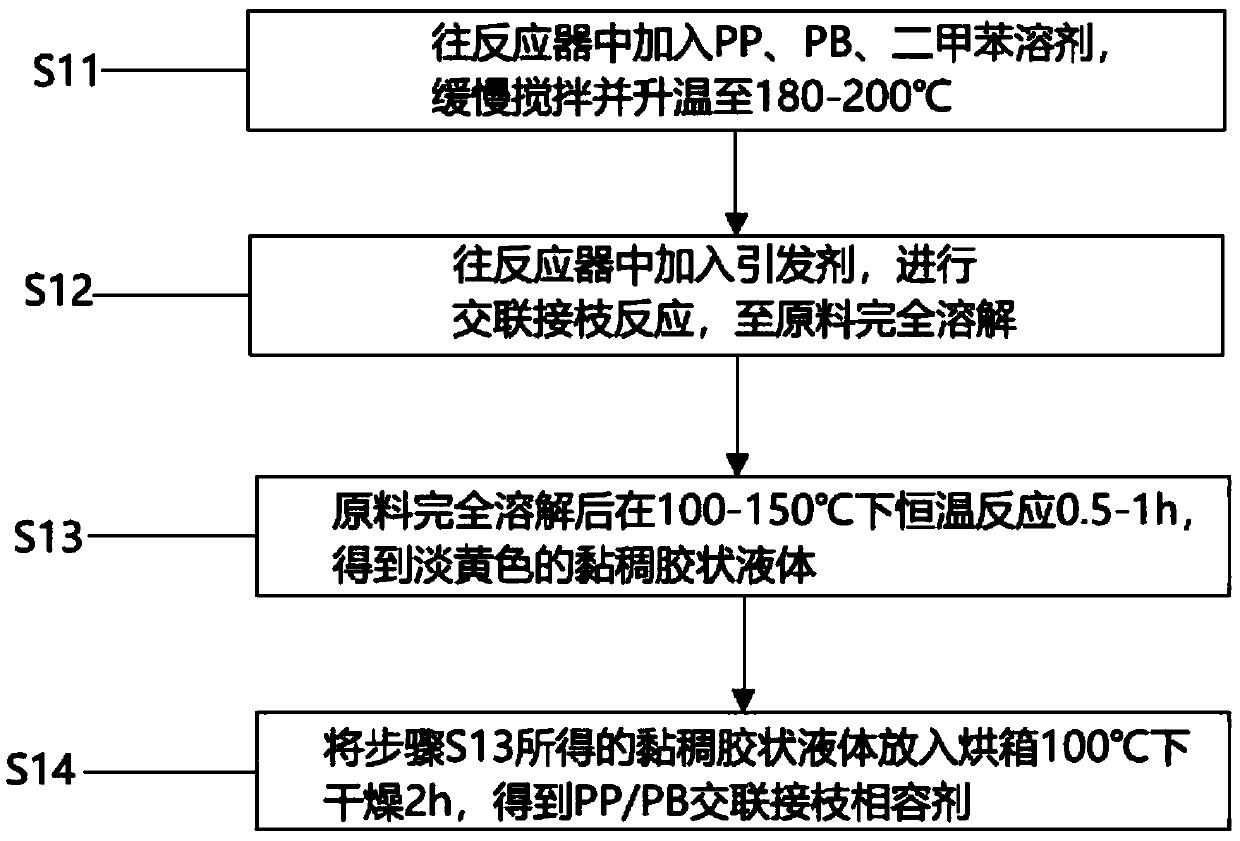

High-fluidity and high-rigidity alloy composite material and preparation method thereof

The invention belongs to the technical field of modified alloy composite materials, and particularly relates to a high-fluidity and high-rigidity alloy composite material and a preparation method thereof. The high-fluidity and high-rigidity alloy composite material comprise the following raw materials by weight. 60-80% of a polypropylene resin, 10-20% of a polybutylene resin, 0.5-3.0% of a compatilizer, 5-15% of a toughening agent, 10-30% of inorganic powder and 1-5% of an auxiliary agent. According to the invention, inorganic powder is well dispersed in a base material on the premise of maintaining excellent comprehensive mechanical properties while the fluidity of the material is improved; a PP / PB cross-linking grafting compatilizer is adopted, and has the same chain segment as a blend,so that the PP / PB cross-linking grafting compatilizer has an emulsifying effect at the PP and PB two-phase interface so as to improve the compatibility of the base material polypropylene / polybutylenealloy system, ensure the high fluidity, the high dispersibility and the high rigidity of the polypropylene / polybutylene alloy material, and achieve the injection molding of large-scale products on general injection molding machines; and the composite material can be widely used in the fields of household electrical appliances, automobiles and the like.

Owner:GREE ELECTRIC APPLIANCES INC

Preparation method of amphipathic non-spherical particles

The invention provides a preparation method of amphipathic non-spherical particles. The preparation method is characterized in that the sizes of seeds, the thickness of shell silicon and the hydrophilicity of the seeds can be controlled by systemically adjusting the amount of an emulsifying agent and the amount of a silane coupling agent, and the growth degree of a new polymer phase can be controlled by controlling the feeding amount and the polymerization time of a second monomer, thus the nanometer / submicron non-spherical particles controllable in shape are obtained. The non-spherical particles prepared by the method have the amphipathy, can realize adsorption and ordered arrangement on a two-phase interface of an oil-phase and water-phase mixed solution, play a role in emulsification and can be used as a surface active agent and the like. The amphipathic non-spherical particles comprise organic-inorganic-organic phases, are different from the single polymer phase commonly reported in literatures and have important significance for the development of novel multi-components materials.

Owner:天津娇强科技有限公司

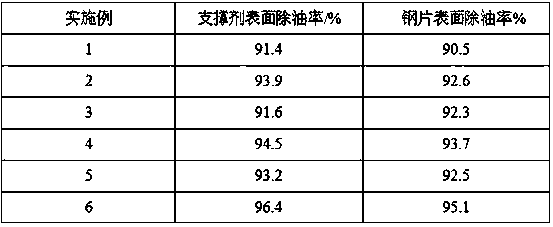

Efficient degreaser and preparation and application methods thereof

InactiveCN109575883AIn line with the development trendReduce the binding forceInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsOil waterOrganic matter

The invention provides an efficient degreaser and preparation and application methods thereof. The efficient degreaser is composed of materials including, by weight percentage, 20.0-25.0% of surfactant, 10.0-15.0% of solvent, 3.0-5.0% of alkali, 2.0-5.0% of alkali and water as balance. According to the efficient degreaser, the surfactant can significantly reduce oil-water interfacial tension and achieves certain emulsifying effects; the solvent can further eliminate organic matters in raw grease to weaken the bonding force between the organic molecules and a tank wall through penetration and further facilitate removal of the raw grease from the tank wall; alkali liquor can neutralize acid content in asphaltene to achieve the aim of efficient cleaning. Besides, the efficient degreaser is free from harm to environment and workers, significant in degreasing effects and consistent to the development trend of degreasers.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

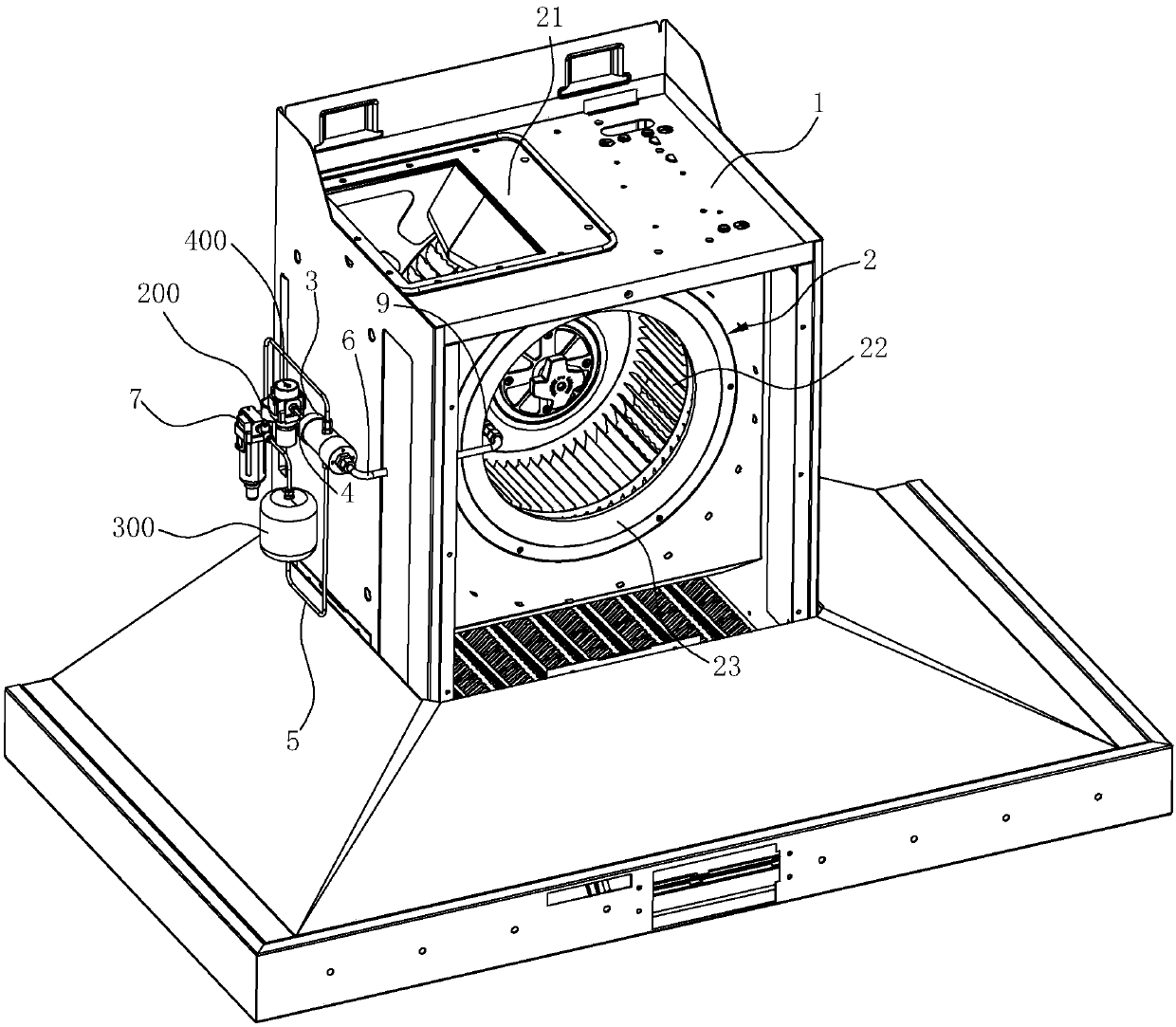

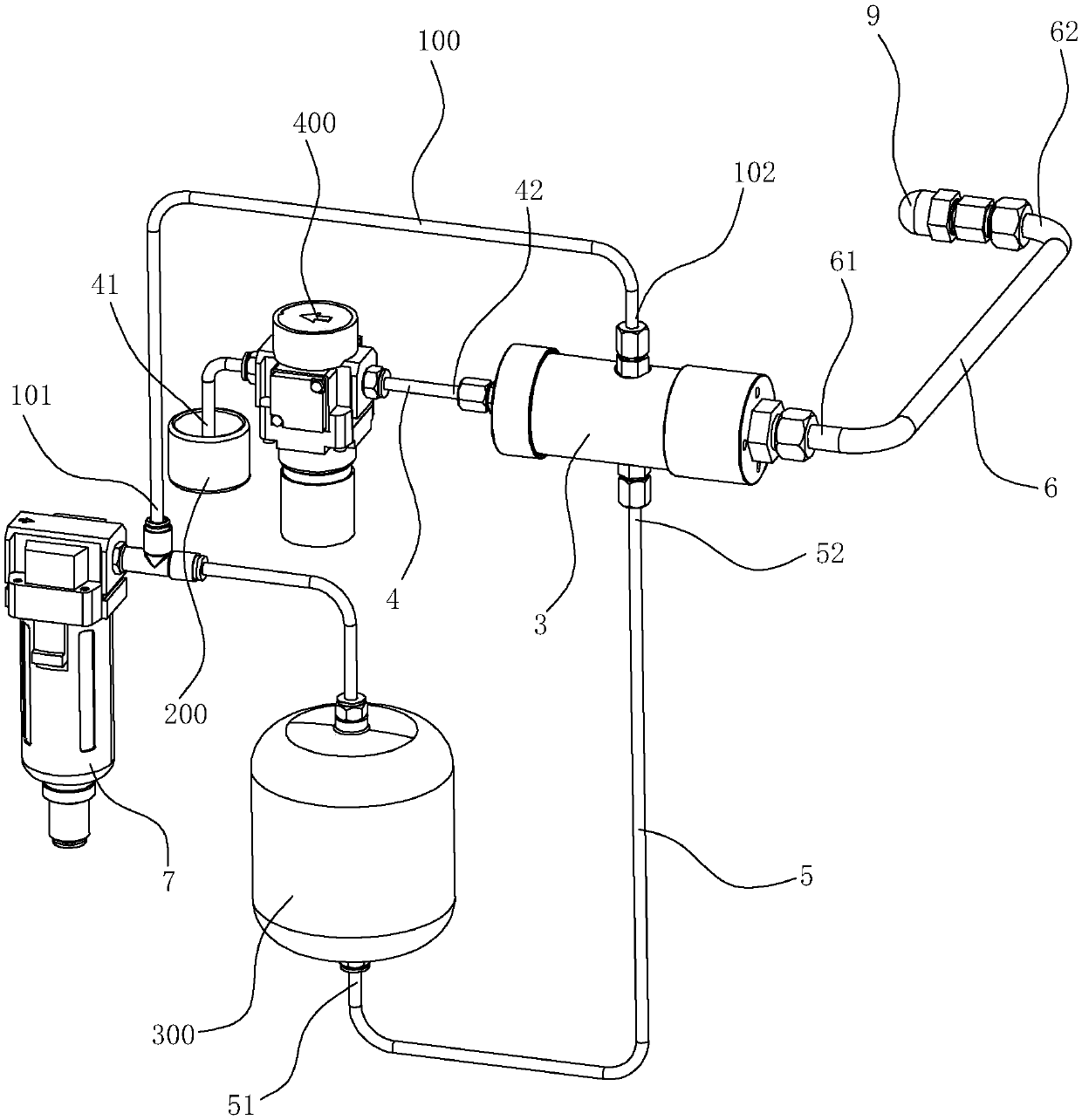

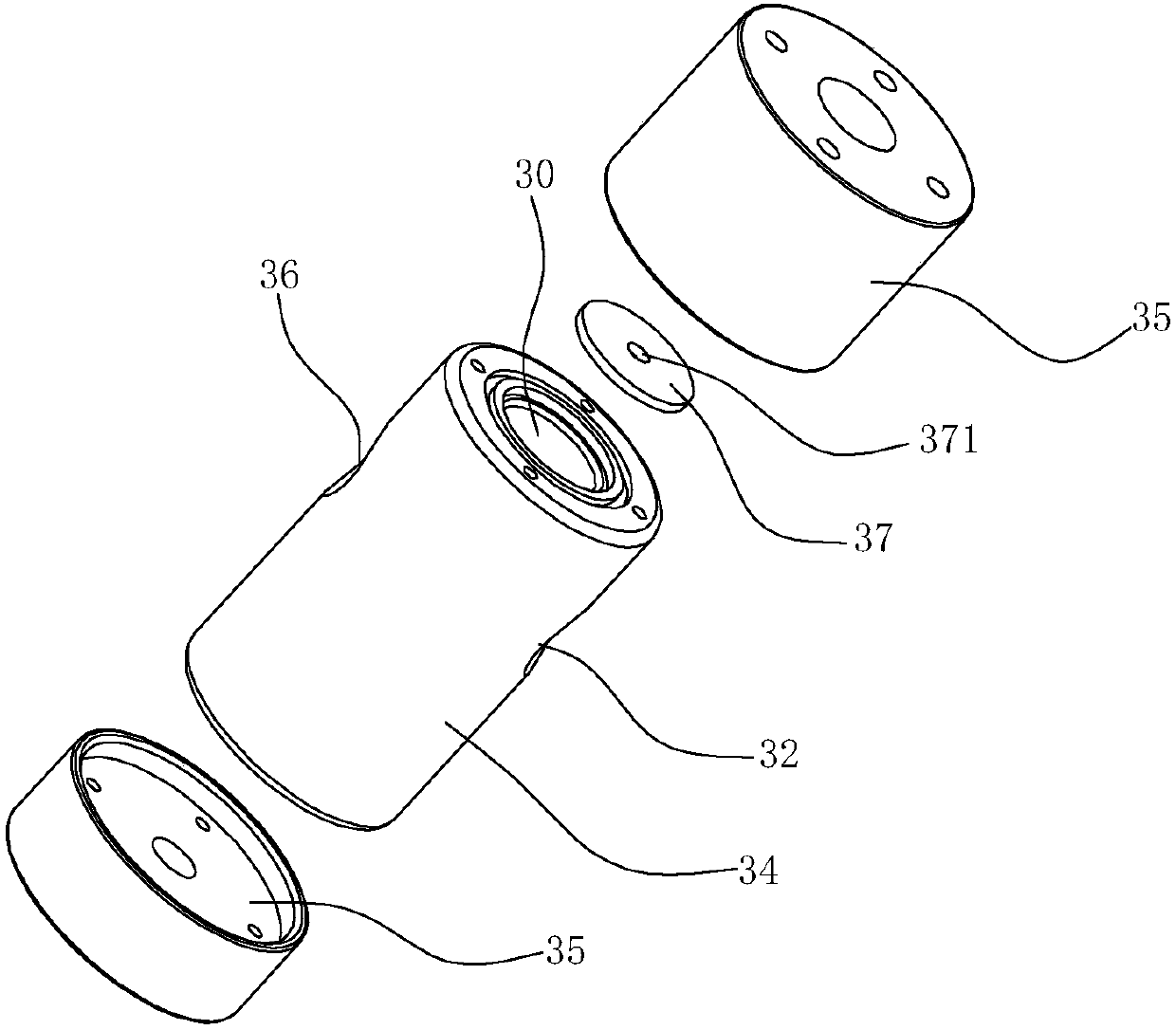

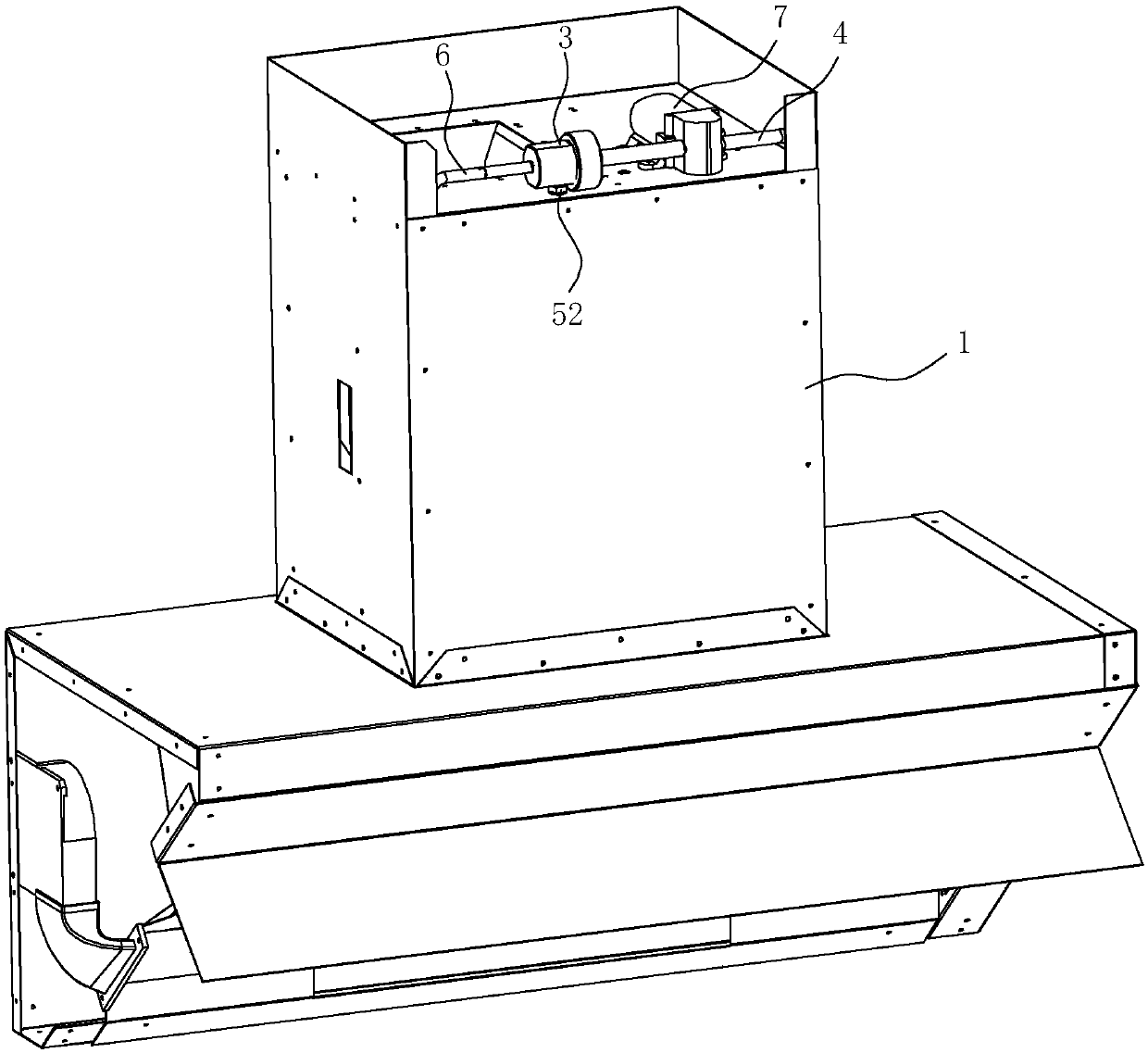

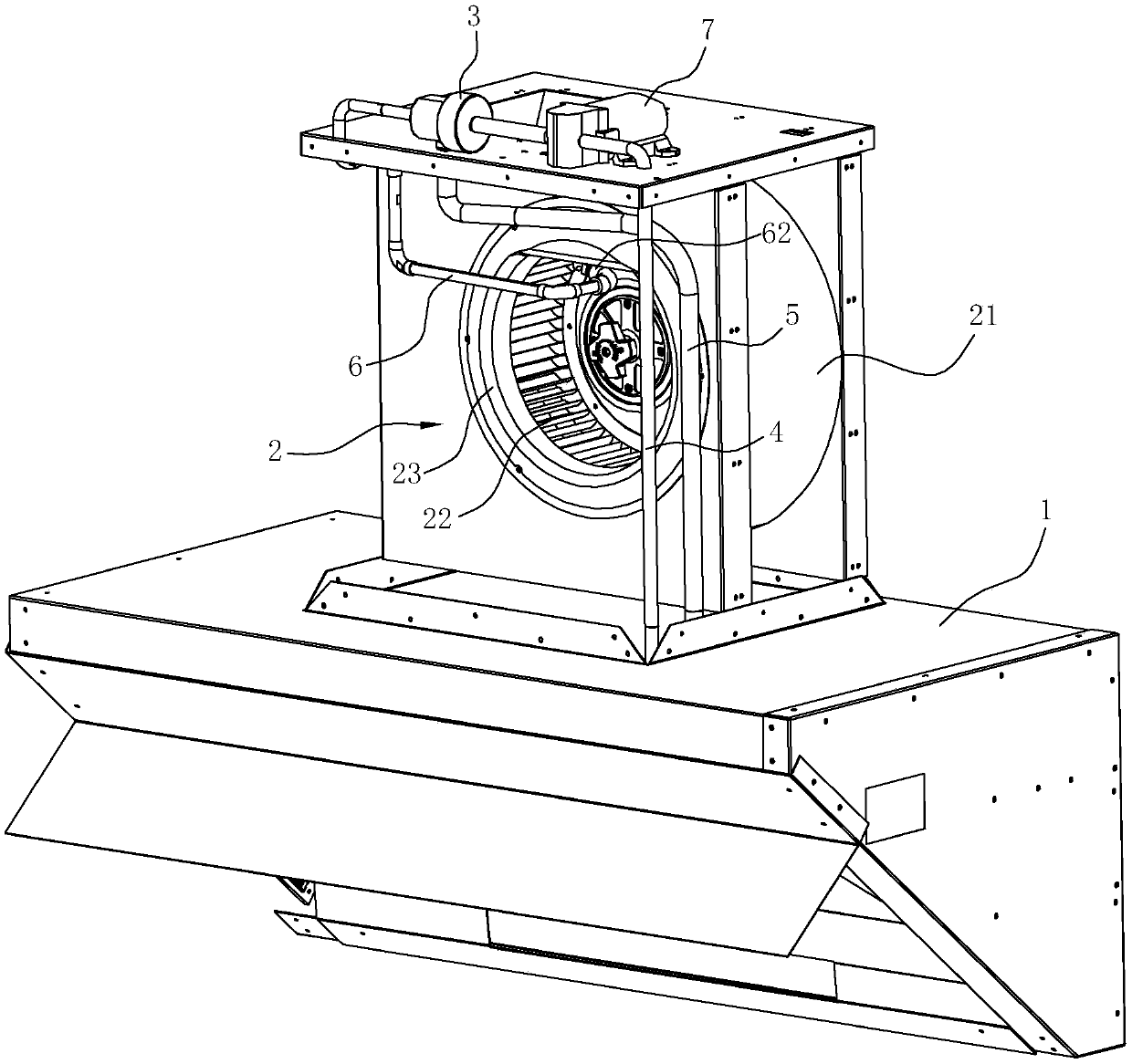

Range hood with self-cleaning function

PendingCN110440316APlay an emulsifying roleIncrease contact timeDomestic stoves or rangesLighting and heating apparatusContact timeWater flow

The invention relates to a range hood with a self-cleaning function. The range hood comprises a shell, a fan, a foaming seat, a first liquid guide pipe, a driving part, a second liquid guide pipe, a gas guide pipe and a third liquid guide pipe, wherein the foaming seat is provided with a mixing chamber; the first liquid guide pipe is provided with a first end opening allowing water to be input, and a second end opening of the first liquid guide pipe communicates with the mixing cavity of the foaming seat; the second liquid guide pipe is provided with a first end opening allowing a detergent toinput, a second end opening of the second liquid guide pipe communicates with the mixing cavity of the foaming seat, and the gas guide pipe communicates with the mixing cavity; and a first end opening of the third liquid guide pipe is connected with an output opening of the mixing cavity, and a second end opening of the third liquid guide pipe extends into the fan. A water flow is sprayed into the mixing cavity of the foaming seat through the first liquid guide pipe, meanwhile, the detergent enters the mixing cavity through the second liquid guide pipe and air enters the mixing cavity throughthe third liquid guide pipe to be mixed with the water flow to form a cleaning medium with foam, the foam can prolong the contact time between the foam and the inner surface of the fan and can emulsify oil contamination, so that the cleaning effect is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

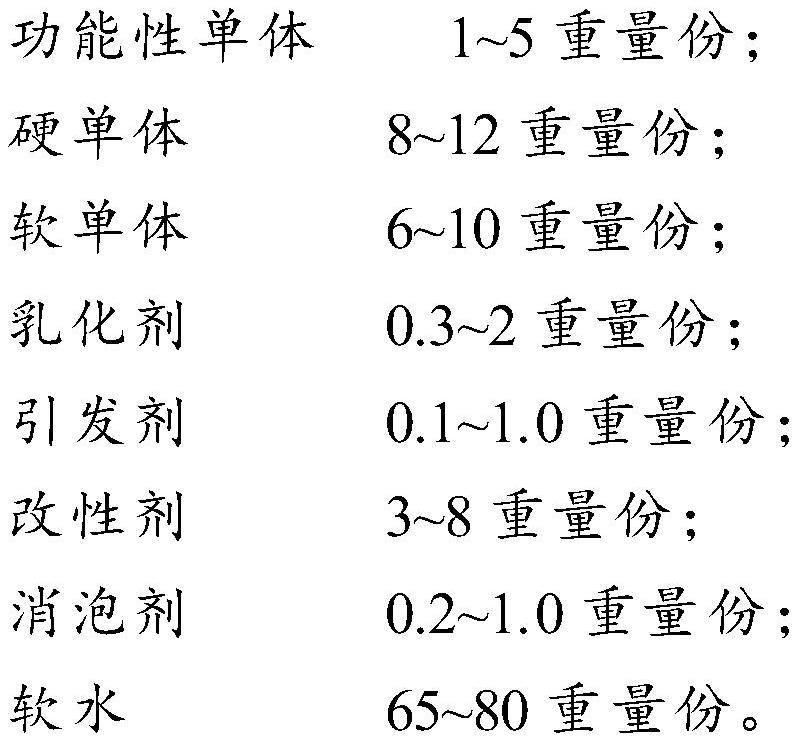

Acrylic emulsion for kraft paper as well as preparation method and application of acrylic emulsion

PendingCN113637112AAdjust the glass transition temperatureGood flexibilityNon-fibrous pulp additionPaper coatingPolymer scienceFunctional monomer

The invention provides an acrylic emulsion for kraft paper. The acrylic emulsion is prepared from a hard monomer, a soft monomer, a functional monomer, an emulsifier, an initiator, a modifier, a defoaming agent and soft water. The invention also provides a preparation method of the acrylic emulsion for kraft paper. The invention further provides composite kraft paper which comprises kraft paper and a coating. A coating formed by coating kraft paper with the acrylic emulsion provided by the invention has good heat sealability and water vapor blocking effect, and the performance reaches the GB / T 36392-2018 food packaging coated paper standard. Used coated cowhide can be recycled and re-pulped, and the acrylic polymer coating on the kraft paper can be used as a filler of paper pulp, so that resources can be recycled.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Soap-free preparation method of fluoropolymer

The invention relates to the technical field of fluoropolymers, in particular to a soap-free preparation method of a fluoropolymer. According to the soap-free preparation method of the fluoropolymer, water is taken as a solvent, a fluorine-containing monomer and perfluorovinyl ether are taken as polymerization monomers, and the fluoropolymer is obtained through a reaction under the combined action of a gaseous chain transfer aid and an inorganic initiator. According to the soap-free preparation method of the fluoropolymer, solid-liquid separation of an obtained polymer emulsion can be achieved in a physical and mechanical mode, and a solid can be directly dried without washing to prepare a finished product, so the manufacturing cost of the fluoropolymer is effectively reduced, and environmental protection is better realized; and the content of auxiliaries and impurities in the prepared product is smaller than 1 ppm.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

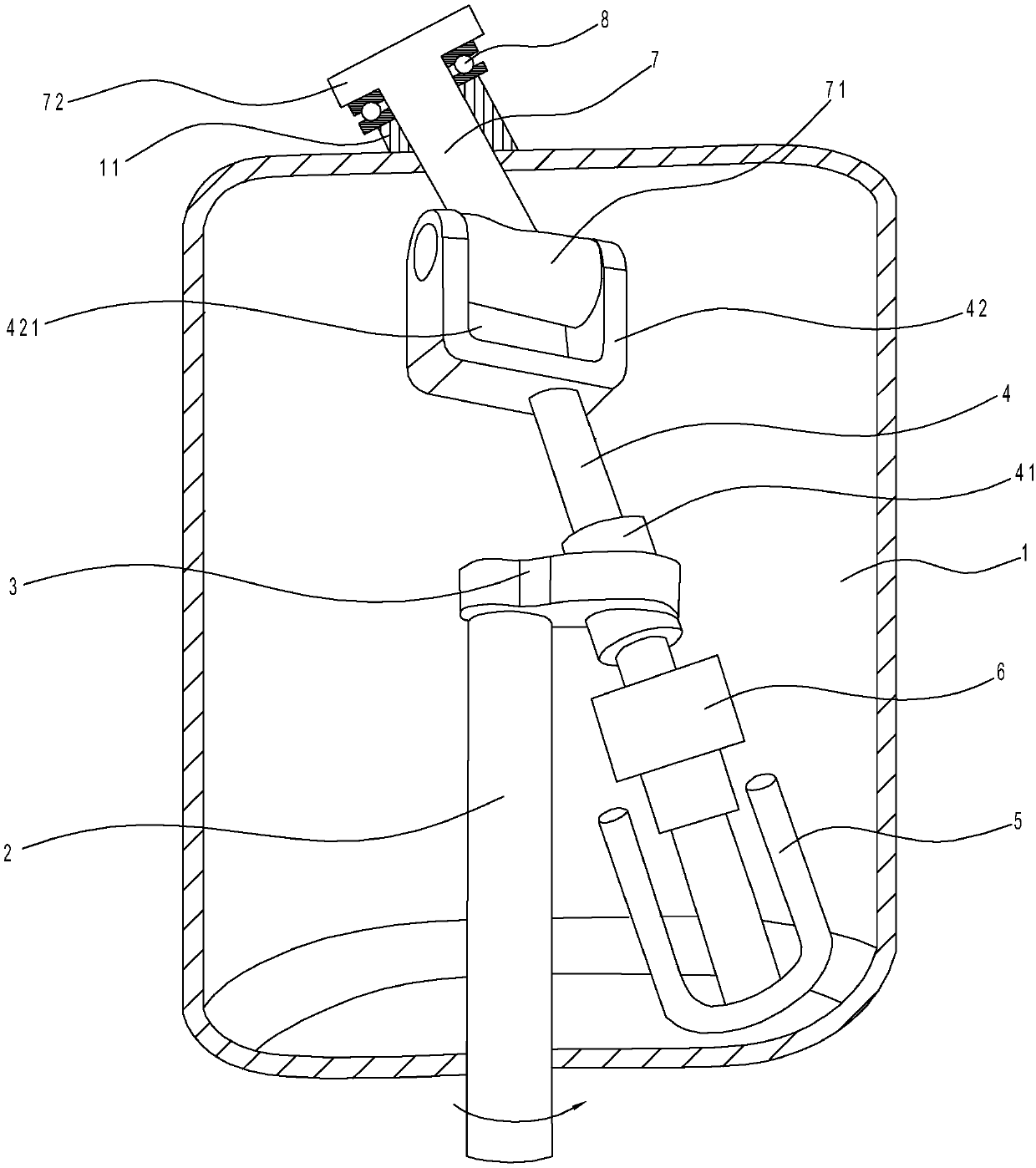

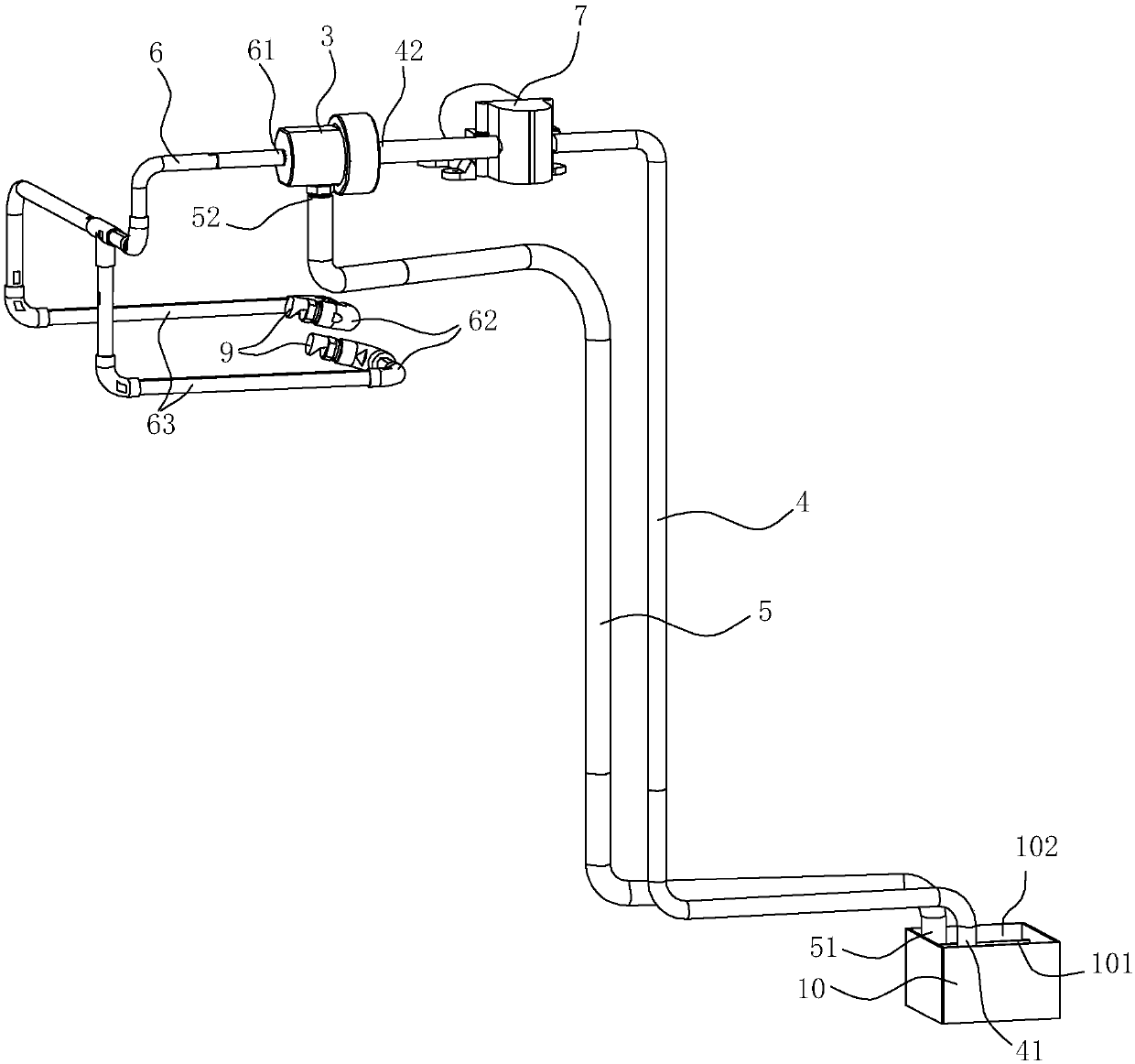

Emulsifying machinedevice

ActiveCN109550429AStir to mix vigorouslyImprove emulsifying abilityRotary stirring mixersMixing methodsEngineering

Owner:太仓中新宝智能装备有限公司

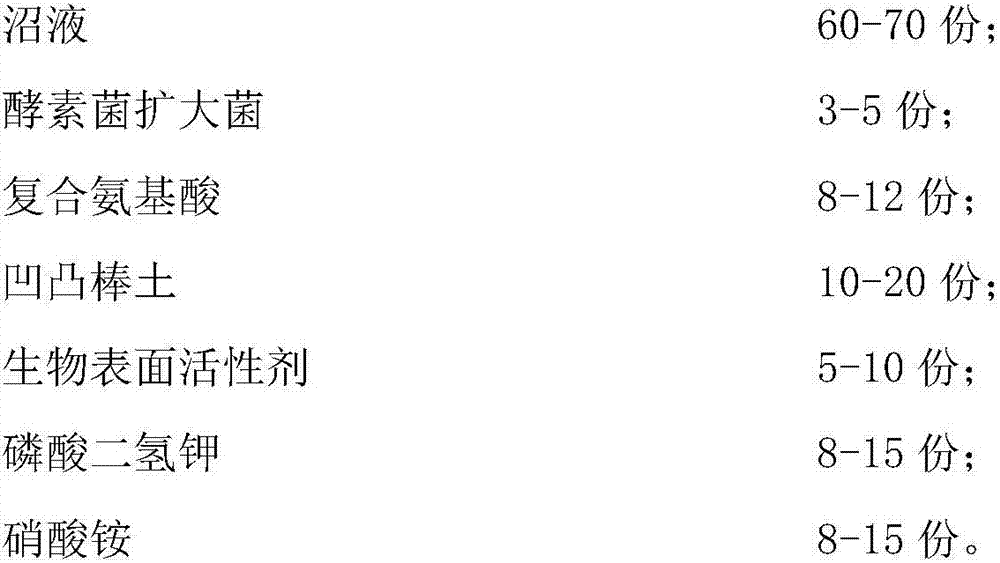

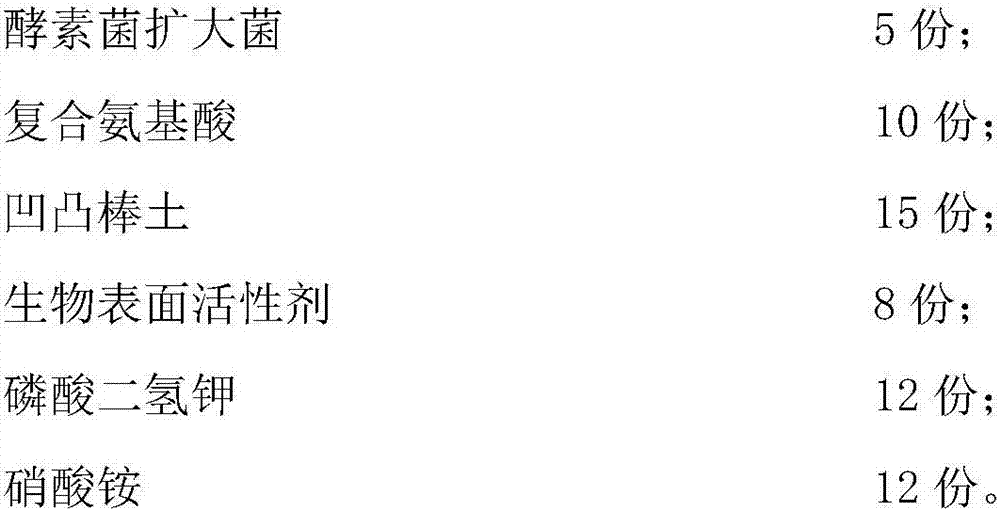

Enzyme microorganism liquid compound fertilizer and preparation method thereof

InactiveCN107500895AHigh in nutrientsImprove stabilityBio-organic fraction processingAlkali orthophosphate fertiliserChemistryNutrient content

The invention discloses an enzyme microorganism liquid compound fertilizer and a preparation method thereof. According to the compound fertilizer, biogas slurry is utilized as a main fertilizer; auxiliary fertilizers such as enzyme microorganism enlarging bacteria, a biological surfactant, attapulgite, compound amino acid, monopotassium phosphate and ammonium nitrate are added; thus, the nutrient content of the fertilizer is improved, and the fertilizer the advantages of greenness and environmental friendliness; the attapulgite has strong water absorption and has viscosity and plasticity when being wet; after being dried, the attapulgite has small shrinkage without obvious cracks; the attapulgite can collapse after being soaked by water to adjust a soil structure, so that the soil is prevented from agglomerating, and fertilizer nutrient absorption is not affected; the biological surfactant has an emulsifying effect, so that stability of the liquid fertilizer is improved; the prepared liquid fertilizer has the advantages of comprehensive nutrient and simple manufacturing technology.

Owner:ANHUI RUIHU BIO FERTILIZER

Bearing inner sleeve polishing oil additive facilitating cleaning

InactiveCN101200619AReduce labor intensityImprove cleaning conditionsSurface-active detergent compositionsGrinding machinesFood additiveOil additive

The present invention discloses a bearing inner cover polishing oil additive which is convenient for cleaning and consists of polishing oil and additive. The quantity of the polishing oil is 95 percent to 97 percent; the quantity of the additive is 3 percent to 5 percent, wherein, the polishing oil contains 97 percent to 98 percent of no.20 machine oil and 2 percent to 3 percent of emery; the additive contains surfactant, cleaning agent and emulsifying oil, and the consumption quantity ratio is 0.5 to 1.5 ®U 9.5 to 10.5 ®U 1.5 to 2.5. The present invention adds the additive into the prior polishing oil, which ensures that the cleaning status of the product which is processed by the method is improved by the corresponding cleaning method under the precondition of not influencing the polishing quality of the bearing inner cover. The present invention lightens the labor intensity of the staff and improves the cleanliness level of the product under the precondition of ensuring the cleaning quality. The time of moving the produce is little, so the unnecessary damage is reduced, which can ensure that the product gyration, the noises etc. which are caused by the damage are reduced by 50 percent. The former form of manually scrubbing by a plurality of persons is changed to the one-person operated mechanical type cleaning, which effectively improves the working efficiency.

Owner:LUOYANG LYC BEARING

Range hood with self-cleaning function

PendingCN109931639APlay an emulsifying roleIncrease contact timeDomestic stoves or rangesLighting and heating apparatusContact timeWater flow

The invention relates to a range hood with a self-cleaning function. The range hood comprises a shell, a fan, a foaming seat, a first liquid guiding pipe, a second liquid guiding pipe, a third liquidguiding pipe and a driving part, the interior of the foaming seat is hollow to form a mixing cavity, the first liquid guiding pipe is provided with a first port for allowing water to be input, a second port of the first liquid guiding pipe communicates with the mixing cavity of the foaming seat, the second liquid guiding pipe is provided with a first port for allowing a detergent to be input, a second port of the second liquid guiding pipe communicates with the mixing cavity of the foaming seat, a first port of the third liquid guiding pipe is connected with an output port of the mixing cavity, and a second port of the third liquid guiding pipe extends into the fan. A water flow is sprayed into the mixing cavity of the foaming seat through the first liquid guiding pipe and is atomized to acertain extent to generate a negative pressure in the mixing cavity, the detergent is sucked into the mixing cavity through the second liquid guiding pipe to be mixed with the water flow to form a cleaning medium with foam, the contact time with the inner surface of the fan can be prolonged through the foam, the foam emulsifies oil contamination, and thus the cleaning effect is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com